Blood dialysis membrane and preparation method thereof

A technology of hemodialysis and collagen, applied in the field of hemodialysis membrane and its preparation, can solve the problems of poor barrier effect and high price of polymer membrane, and achieve good water permeability, good permeability, good bacteria and virus barrier effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

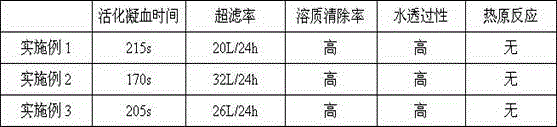

Examples

Embodiment 1

[0025] A hemodialysis membrane, which is mainly made of the following raw materials in proportion by mass: 21 parts of collagen, 16 parts of silk protein, 8 parts of silk fibroin, 7 parts of sericin, 11 parts of cellulose, 2 parts of polyethersulfone, 2 parts of sulfonated polyethersulfone, 7 parts of heparin, 3 parts of lysine, 4 parts of cellulose acetate, 9 parts of methyl acrylate, 14 parts of polyacrylamide, 2 parts of sodium bicarbonate, 32 parts of deionized water.

[0026] A preparation method for a hemodialysis membrane, comprising the following steps:

[0027] (1) Dissolve sodium bicarbonate in deionized water, adjust the pH to 8.2 after completely dissolving; add collagen, silk protein, silk fibroin and sericin, stir to dissolve and store at 4°C for 10 minutes;

[0028] (2) Put cellulose, polyethersulfone, sulfonated polyethersulfone, heparin, lysine, cellulose acetate, methyl acrylate and polyacrylamide in a reaction kettle at a temperature of 480°C and a pressure ...

Embodiment 2

[0032] A hemodialysis membrane, mainly made of the following raw materials according to the ratio of parts by mass: 39 parts of collagen, 34 parts of silk protein, 15 parts of silk fibroin, 11 parts of sericin, 22 parts of cellulose, 12 parts of polyethersulfone, 5 parts of sulfonated polyethersulfone, 19 parts of heparin, 12 parts of lysine, 9 parts of cellulose acetate, 18 parts of methyl acrylate, 23 parts of polyacrylamide, 8 parts of sodium bicarbonate, 54 parts of deionized water.

[0033] A preparation method for a hemodialysis membrane, comprising the following steps:

[0034] (1) Dissolve sodium bicarbonate in deionized water, adjust the pH to 9.2 after completely dissolving; add collagen, silk protein, silk fibroin and sericin, stir and dissolve, store at 6°C for 23 minutes;

[0035] (2) Put cellulose, polyethersulfone, sulfonated polyethersulfone, heparin, lysine, cellulose acetate, methyl acrylate and polyacrylamide in a reaction kettle at a temperature of 725°C an...

Embodiment 3

[0039] A hemodialysis membrane, mainly made of the following raw materials according to the mass ratio: 55 parts of collagen, 42 parts of silk protein, 19 parts of silk fibroin, 15 parts of sericin, 25 parts of cellulose, 15 parts of polyethersulfone, 7 parts of sulfonated polyethersulfone, 22 parts of heparin, 13 parts of lysine, 11 parts of cellulose acetate, 22 parts of methyl acrylate, 29 parts of polyacrylamide, 11 parts of sodium bicarbonate, 60 parts of deionized water.

[0040] A preparation method for a hemodialysis membrane, comprising the following steps:

[0041] (1) Dissolve sodium bicarbonate in deionized water, adjust the pH to 9.6 after completely dissolving; add collagen, silk protein, silk fibroin and sericin, stir to dissolve and store at 8°C for 26 minutes;

[0042] (2) Put cellulose, polyethersulfone, sulfonated polyethersulfone, heparin, lysine, cellulose acetate, methyl acrylate and polyacrylamide in a reaction kettle at a temperature of 760°C and a pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com