Refinement method of erythromycin thiocyanate

A technology of erythromycin thiocyanate and a refining method, applied in the field of medicine, can solve problems such as low light transmittance of finished products, and achieve the effects of high light transmittance, low production and operation cost, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

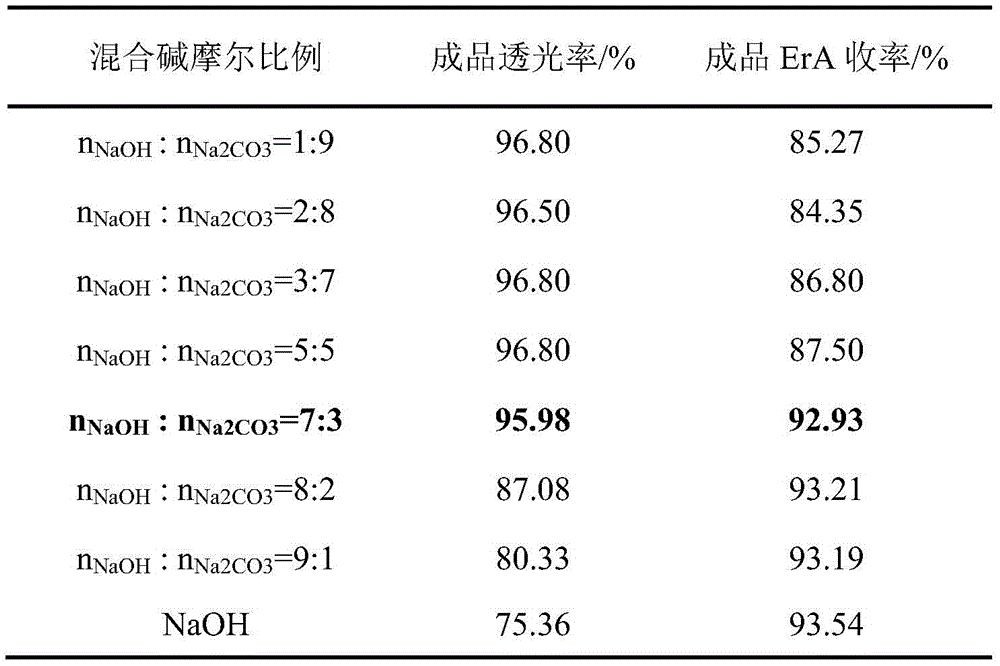

[0032] Embodiment 1 erythromycin thiocyanate refining method of the present invention

[0033] Get 400 grams of erythromycin thiocyanate crude product (moisture content 31.17%, erythromycin titer is 556u / mg; HPLC external standard method detects, contains erythromycin A73.37% in terms of dry product, contains erythromycin B3 .1%, containing erythromycin C1.72%, containing erythromycin E3.99%), adding methanol (adding 2.3 liters of methanol per billion units of erythromycin), stirring, using mixed alkali solution (sodium hydroxide and The molar ratio of sodium carbonate is 7:3, the concentration is 24%) to adjust the pH to 9.5, and the temperature is raised to 38±2°C, the insoluble matter is removed by centrifugation, and the filter cake is washed with methanol (washing with 0.2 liter of methanol per billion units of erythromycin) , combine the washing liquid and the centrifugation liquid, heat up to 41±2°C, add 40% sodium thiocyanate solution (0.4 mole sodium thiocyanate is ad...

Embodiment 2

[0037] Embodiment 2 erythromycin thiocyanate refining method of the present invention

[0038] Get 400 grams of erythromycin thiocyanate crude product (moisture content 31.17%, erythromycin titer is 556u / mg; HPLC external standard method detects, contains erythromycin A73.37% in terms of dry product, contains erythromycin B3 .1%, containing erythromycin C1.72%, containing erythromycin E3.99%), adding methanol (adding 2.3 liters of methanol per billion units of erythromycin), stirring, using mixed alkali solution (sodium hydroxide and The molar ratio of sodium carbonate is 7:3, the concentration is 20%) to adjust the pH to 9.4, and the temperature is raised to 38±2°C, the insoluble matter is removed by centrifugation, and the filter cake is washed with methanol (washing with 0.2 liter of methanol per billion units of erythromycin) , combine the washing liquid and the centrifugation liquid, heat up to 41±2°C, add 40% sodium thiocyanate solution (0.4 mole sodium thiocyanate is ad...

Embodiment 3

[0040] Embodiment 3 erythromycin thiocyanate refining method of the present invention

[0041]Get 400 grams of erythromycin thiocyanate crude product (water content 25.5%, erythromycin titer is 604u / mg; HPLC external standard method detects, contains erythromycin A77.72% in terms of dry product, contains erythromycin B2 .1%, containing erythromycin C2.9%, containing erythromycin E3.6%), add methanol (every billion units of erythromycin add 2.1 liters of methanol), stir, use mixed alkali solution (sodium hydroxide and The molar ratio of sodium carbonate is 6:4, the concentration is 20%) to adjust the pH to 9.5, and the temperature is raised to 38±2°C, the insoluble matter is removed by centrifugation, and the filter cake is washed with methanol (washing with 0.2 liter of methanol per billion units of erythromycin) , combine the washing liquid and the centrifugation liquid, heat up to 41±2°C, add 40% sodium thiocyanate solution (0.4 mole sodium thiocyanate is added for every mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com