Graphene reinforced copper-rare earth based electrical contact material and preparing method thereof

An electrical contact material, graphene technology, applied in the directions of contacts, circuits, electrical switches, etc., can solve the problems of reducing the electrical conductivity and thermal conductivity of copper contact materials, and it is difficult to obtain comprehensive performance copper-based contact materials. High density, low production cost, fast cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

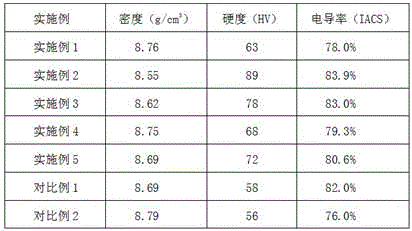

Examples

Embodiment 1

[0031] (1) The copper-rare earth alloy is made into 200-mesh alloy powder by centrifugal atomization method, the rare earth in the copper-rare earth is cerium-rich mixed rare earth metal, and the weight content is 0.05% of the copper-rare earth alloy.

[0032] (2) Graphene and alloy powder are put into a ball mill and mixed in a weight ratio of 0.1:99.9 to make a uniformly mixed powder. Graphene is 1-10 layers. The process parameters of the ball mill are: the ball mill tank is evacuated first and then argon protection is introduced, the speed is 100r / min, the ball mill is 15 minutes, stop for 5 minutes, rotate clockwise and counterclockwise alternately, and the total mixing time is 6h.

[0033] (3) Put the powder mixed in step (2) into the mold for cold press molding, the pressure is 400MPa, and the holding time is 5 minutes. The cold-pressed parts are sintered under the protection of argon, and the vacuum degree is 1.0*10 -3 Pa, the sintering temperature is 900°C, and the ho...

Embodiment 2

[0036] (1) The copper-rare earth alloy is made into 300-mesh alloy powder by ultrasonic atomization. The rare earth in the copper-rare earth is lanthanum-rich mixed rare earth metal, and the weight content is 0.5% of the copper-rare earth alloy.

[0037] (2) Put graphene and alloy powder into a ball mill and mix them in a weight ratio of 3.0:97.0 to make a uniformly mixed powder. Graphene is 1-10 layers. The process parameters of the ball mill are: the ball mill tank is evacuated first and then argon protection is introduced, the speed is 250r / min, the ball mill is 10 minutes, stop for 5 minutes, rotate clockwise and counterclockwise alternately, and the total mixing time is 2h.

[0038] (3) Put the powder mixed in step (2) into the mold for cold press molding, the pressure is 600MPa, and the holding time is 3 minutes. The cold-pressed molded parts are sintered under the protection of hydrogen, and the vacuum degree is 5.0*10 -1 Pa, the sintering temperature is 700°C, and the...

Embodiment 3

[0041] (1) The copper-rare earth alloy is made into 200-mesh alloy powder by gas atomization method, the rare earth is cerium-rich mixed rare earth metal, and the weight content is 3.0% of the copper-rare earth alloy.

[0042] (2) Put the graphene and alloy powder into a ball mill and mix the powder in a weight ratio of 2:98 to make a uniformly mixed powder. Graphene is 1-10 layers. The process parameters of the ball mill are: the ball mill tank is evacuated first and then argon protection is introduced, the speed is 200r / min, the ball mills for 15 minutes, stops for 5 minutes, rotates clockwise and counterclockwise alternately, and the total mixing time is 2h.

[0043] (3) Put the powder mixed in step (2) into the mold for cold press molding, the pressure is 500MPa, the pressure holding time is 3 minutes, the cold pressed molded parts are sintered under the protection of argon, and the vacuum degree is 1.0*10 -1 Pa, the sintering temperature is 750°C, and the holding time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com