Preparation method of phosphorus-doped two-dimensional carbon material and application thereof in sodium-ion battery

A two-dimensional carbon material, sodium-ion battery technology, applied in battery electrodes, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of poor sodium storage activity, difficult to effectively insert, etc., achieves low cost, controllable conditions, and is conducive to The effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

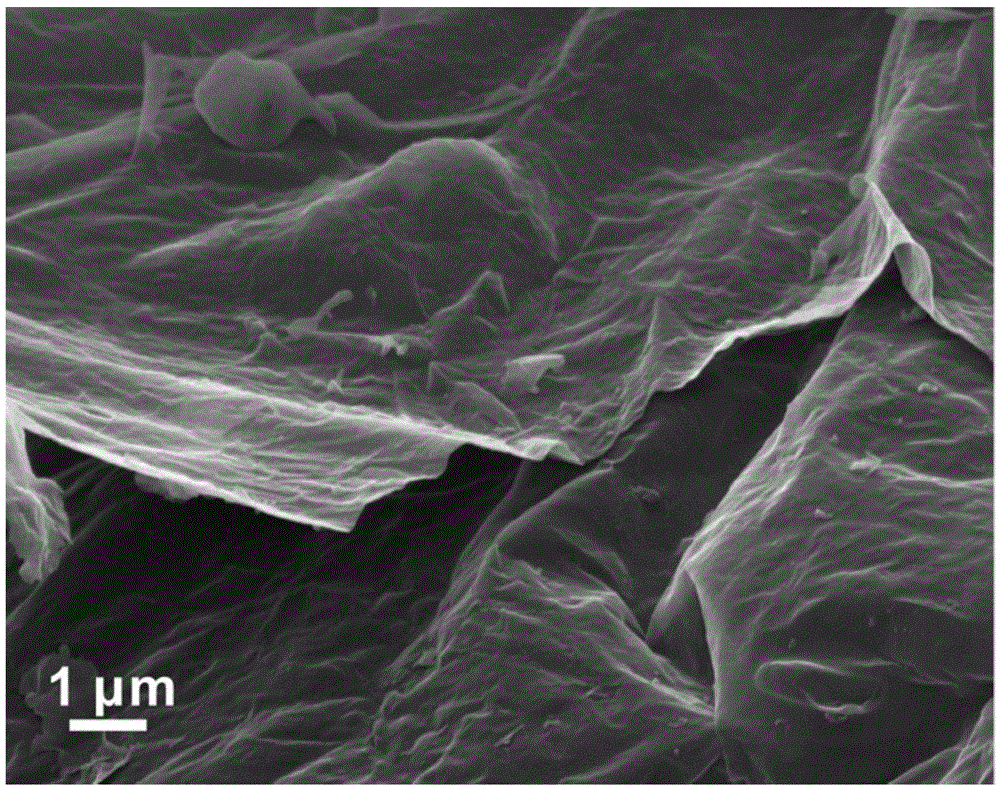

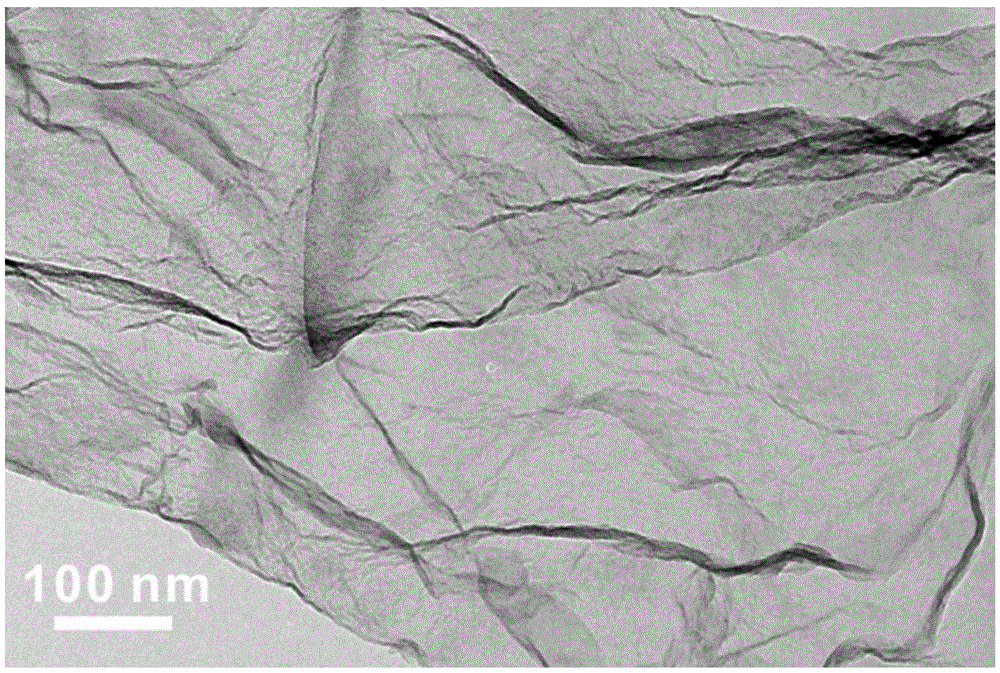

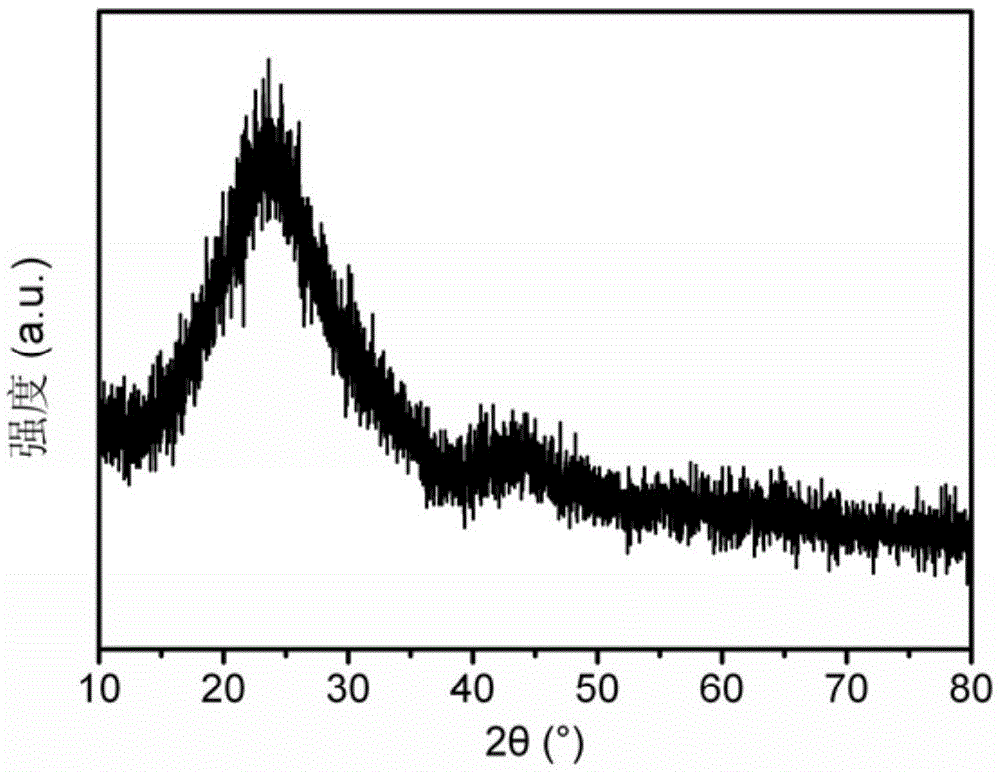

[0031] Mix 0.4g of carbon quantum dots and 4.0g of sodium dihydrogen phosphate evenly, and then calcinate them at 900°C for 2h under the protection of an inert gas, with a heating rate of 10°C / min, and cool down naturally. Grind the calcined product into powder, add an appropriate amount of concentrated hydrochloric acid, adjust its pH to neutral, centrifuge at 8000r / min for 10min, wash with deionized water for 5 times, and vacuum dry at 100°C for 12h to obtain a black powder . Its scanning electron microscope picture is figure 1 , it can be seen that the product is a large area of nano flakes. figure 2 Its transmission electron microscope picture is consistent with the scanning electron microscope result. image 3 Is its X-ray diffraction spectrum, the product obtained is amorphous carbon. X-ray photoelectron spectroscopy results ( Figure 4 ) shows that the phosphorus content in the obtained two-dimensional carbon material is 1.39At%. Adsorption and desorption test r...

Embodiment 2

[0033] Mix 0.4g of carbon quantum dots and 4.0g of sodium dihydrogen phosphate evenly, and then calcinate them at 800°C for 2h under the protection of an inert gas, with a heating rate of 10°C / min, and cool down naturally. Grind the calcined product into powder, add an appropriate amount of concentrated hydrochloric acid, adjust its pH to neutral, centrifuge at 8000r / min for 10min, wash with deionized water for 5 times, and vacuum dry at 100°C for 12h to obtain a black powder . Figure 6 It is its transmission electron microscope picture, and two-dimensional nano-sheets can be clearly observed. X-ray photoelectron spectroscopy results ( Figure 7 ) shows that the phosphorus content in the obtained two-dimensional carbon material is 0.75At%.

Embodiment 3

[0035] 0.4g of carbon quantum dots and 3.2g of sodium dihydrogen phosphate were mixed evenly, and then calcined at 900°C for 2h under the protection of an inert gas, with a heating rate of 10°C / min, and the temperature was naturally lowered. Grind the calcined product into powder, add an appropriate amount of concentrated hydrochloric acid, adjust its pH to neutral, centrifuge at 8000r / min for 10min, wash with deionized water for 5 times, and vacuum dry at 100°C for 12h to obtain a black powder . Figure 8 It is its transmission electron microscope picture, and two-dimensional nano-sheets can be clearly observed. X-ray photoelectron spectroscopy results ( Figure 9 ) shows that the phosphorus content in the obtained two-dimensional carbon material is 1.30At%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Inverse specific capacity | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com