Method and equipment for drying and fermenting feed at low temperature

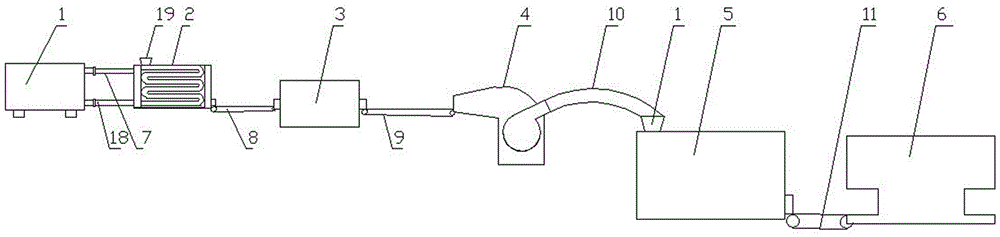

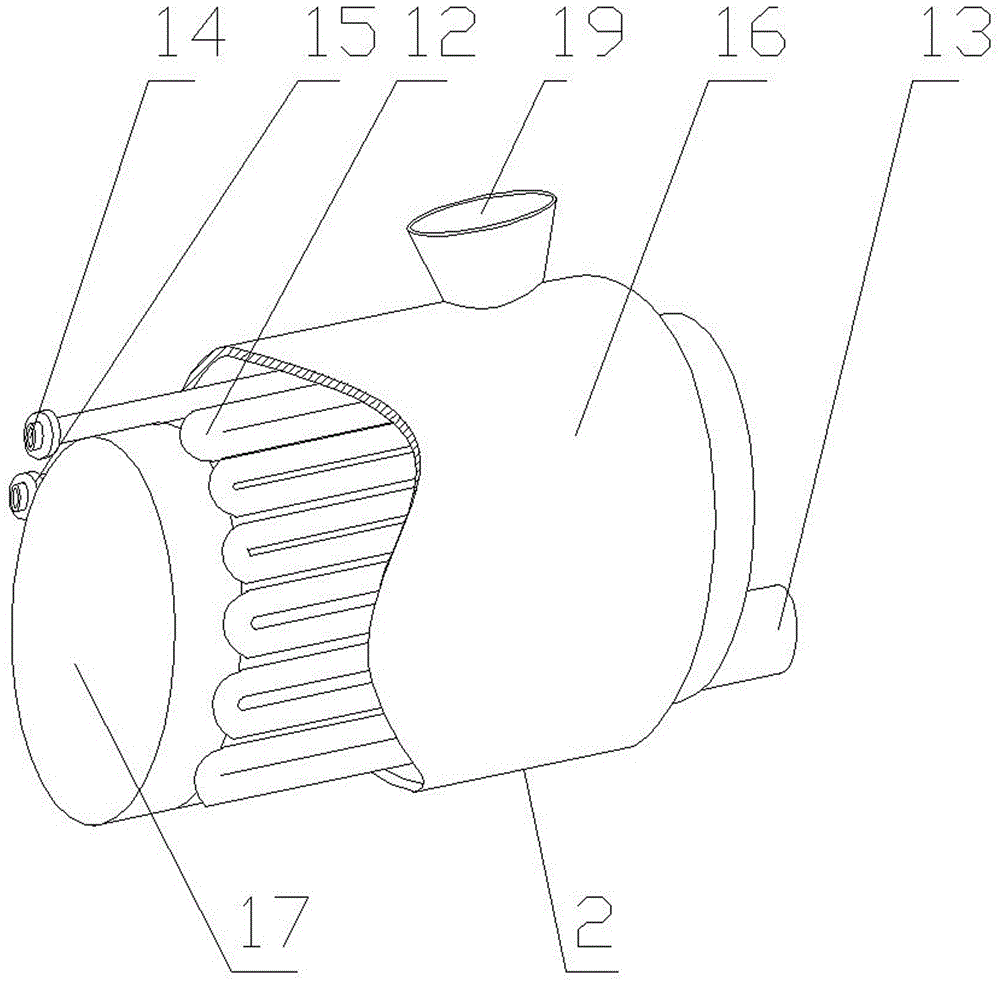

A fermented feed and low-temperature drying technology, which is applied in drying, dryers, animal feed, etc., can solve the problems of reducing the survival amount of probiotics, large temperature difference between inlet temperature and outlet temperature, waste of resources, etc., to improve nutritional value , reduce production costs, and ensure the survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

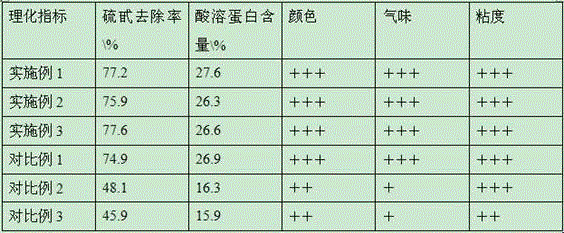

Embodiment 1

[0025] A method for drying fermented feed at low temperature, comprising the following steps:

[0026] (1) Sterilization of raw materials: the mass fraction is rapeseed meal with a total weight of raw materials of 97.8%, the mass fraction is calcium hydrogen phosphate with a total weight of raw materials of 1.2%, the mass fraction is stone powder with a total weight of raw materials of 0.7%, and the mass fraction is The total weight of raw materials is mixed with 0.3% salt, and then steam sterilized for 40 minutes.

[0027] (2) Inoculation of probiotics: Inoculate the sterilized raw materials with the bacterial liquid of Aspergillus oryzae AO-03 for aerobic fermentation, and measure the content of glucosinolates and acid-soluble proteins. When monitoring the contents of glucosinolates and acid-soluble proteins online, when When the removal rate of glucosinolates and the content of acid-soluble protein begin to decrease, the bacterial solution of lactic acid bacteria PL-14 and ...

Embodiment 2

[0033] A method for drying fermented feed at low temperature, comprising the following steps:

[0034] (1) Sterilization of raw materials: the mass fraction is rapeseed meal with a total weight of raw materials of 97.8%, the mass fraction is calcium hydrogen phosphate with a total weight of raw materials of 1.2%, the mass fraction is stone powder with a total weight of raw materials of 0.7%, and the mass fraction is The total weight of raw materials is mixed with 0.3% salt, and then steam sterilized for 40 minutes.

[0035] (2) Inoculation of probiotics: Inoculate the sterilized raw material with Aspergillus oryzae AO-03 bacterial liquid for aerobic fermentation, measure the content of glucosinolate and acid-soluble protein, when the removal rate of glucosinolate and acid-soluble protein begin to decline At the same time, the bacterium solution of lactic acid bacteria PL-14 and Saccharomyces cerevisiae SC-11 was added for further facultative anaerobic fermentation, and the fer...

Embodiment 3

[0041] A method for drying fermented feed at low temperature, comprising the following steps:

[0042] (1) Sterilization of raw materials: the mass fraction is rapeseed meal with a total weight of raw materials of 97.8%, the mass fraction is calcium hydrogen phosphate with a total weight of raw materials of 1.2%, the mass fraction is stone powder with a total weight of raw materials of 0.7%, and the mass fraction is The total weight of raw materials is mixed with 0.3% salt, and then steam sterilized for 40 minutes.

[0043] (2) Inoculation of probiotics: Inoculate the sterilized raw material with Aspergillus oryzae AO-03 bacterial liquid for aerobic fermentation, measure the content of glucosinolate and acid-soluble protein, when the removal rate of glucosinolate and acid-soluble protein begin to decline At the same time, the bacterium solution of lactic acid bacteria PL-14 and Saccharomyces cerevisiae SC-11 was added for further facultative anaerobic fermentation, and the fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com