Chitosan-based hemostatic material and preparation method thereof

A hemostatic material, chitosan technology, applied in the field of medical materials, can solve the problem of limited hemostatic effect, achieve good anti-adhesion effect, simple preparation method, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

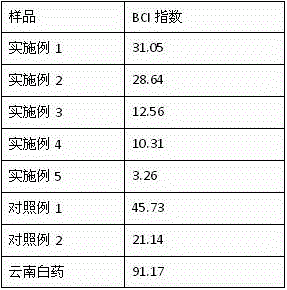

Examples

Embodiment 1

[0020] A chitosan-based hemostatic material prepared from the following raw materials in parts by mass: 40 parts of chitosan, 12 parts of corn starch, 5 parts of whey protein, 5 parts of wheat starch, 5 parts of glucose, and 5 parts of sodium alginate , 10 parts of pectin, 4 parts of lecithin, 4 parts of citric acid, 3 parts of sodium fumarate, 4 parts of sodium chloride, 15 parts of glycerin.

[0021] The preparation method comprises the steps of:

[0022] 1) Mix chitosan, glucose, pectin and polyol evenly, add citric acid, stir evenly, add sodium alginate and sodium fumarate, heat to 65°C and mix for cross-linking reaction for 5 hours;

[0023] 2) Add corn starch, whey protein and wheat starch to a small amount of water to moisten, mix and stir evenly, heat to 50°C, and stir for 40 minutes to obtain a viscous mixture;

[0024] 3) Add the mixture of step 2) and the remaining components into the reaction solution of step 1), continue to stir for 20 minutes, cool down to room ...

Embodiment 2

[0026] A chitosan-based hemostatic material prepared from the following raw materials in parts by mass: 20 parts of chitosan, 8 parts of corn starch, 1 part of whey protein, 2 parts of wheat starch, 1 part of glucose, and 2 parts of sodium alginate , 2 parts of pectin, 1 part of lecithin, 1 part of citric acid, 1 part of sodium fumarate, 1 part of sodium chloride, 8 parts of glycerin.

[0027] The preparation method comprises the steps of:

[0028] 1) Mix chitosan, glucose, pectin and polyol evenly, add citric acid, stir evenly, add sodium alginate and sodium fumarate, heat to 65°C and mix for cross-linking reaction for 5 hours;

[0029] 2) Add corn starch, whey protein and wheat starch to a small amount of water to moisten, mix and stir evenly, heat to 50°C, and stir for 40 minutes to obtain a viscous mixture;

[0030] 3) Add the mixture of step 2) and the remaining components into the reaction solution of step 1), continue to stir for 20 minutes, cool down to room temperatu...

Embodiment 3

[0032] A chitosan-based hemostatic material prepared from the following raw materials in parts by mass: 35 parts of chitosan, 11 parts of corn starch, 4 parts of whey protein, 4 parts of wheat starch, 4 parts of glucose, and 3.8 parts of sodium alginate , 8 parts of pectin, 3 parts of lecithin, 3.4 parts of citric acid, 2.3 parts of sodium fumarate, 3 parts of sodium chloride, 13 parts of ethanol, 5 parts of vitamin C, and 2.3 parts of vitamin E.

[0033] The preparation method comprises the steps of:

[0034] 1) Mix chitosan, glucose, pectin and polyol evenly, add citric acid, stir evenly, add sodium alginate and sodium fumarate, heat to 65°C and mix for cross-linking reaction for 5 hours;

[0035] 2) Add corn starch, whey protein and wheat starch to a small amount of water to moisten, mix and stir evenly, heat to 50°C, and stir for 40 minutes to obtain a viscous mixture;

[0036] 3) Add the mixture of step 2) and the remaining components into the reaction solution of step 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com