Stir friction eutectic reaction welding method for lap joint of dissimilar metal

A eutectic reaction, friction stir technology, used in metal processing, metal processing equipment, welding/welding/cutting items, etc., can solve the problems of cracks in the interface structure, uneven weld bead, low fracture load, etc., to reduce tool Wear, process simplification, effect of increased soldering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

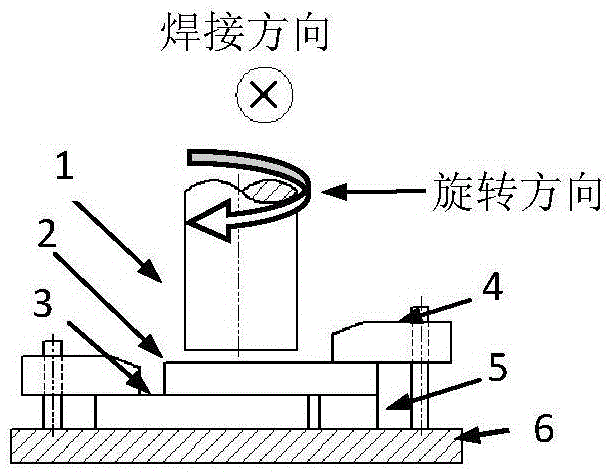

[0053] Example 1: Preparation of Cu / Al lap joints by single pass friction stir eutectic reaction welding

[0054] Commercially available pure copper plate T2 and pure aluminum 1060 with a thickness of 2mm (measured 1.96mm) are selected as the parts to be welded, and the specifications are 100×60×2mm. The assembly method of lap joint is adopted, the area of the lap area is 100×30mm, the upper plate is copper plate, and the lower plate is aluminum plate, such as figure 1 shown. The material of the stirring head is 1Cr13 martensitic stainless steel, the diameter D=20mm, and no needle. The joint quality was evaluated by surface forming quality, shear strength and interface compactness. The welding process parameters are shown in Table 1.

[0055] Table 1. Process parameters of joint preparation by Cu / Al friction stir eutectic reaction welding

[0056]

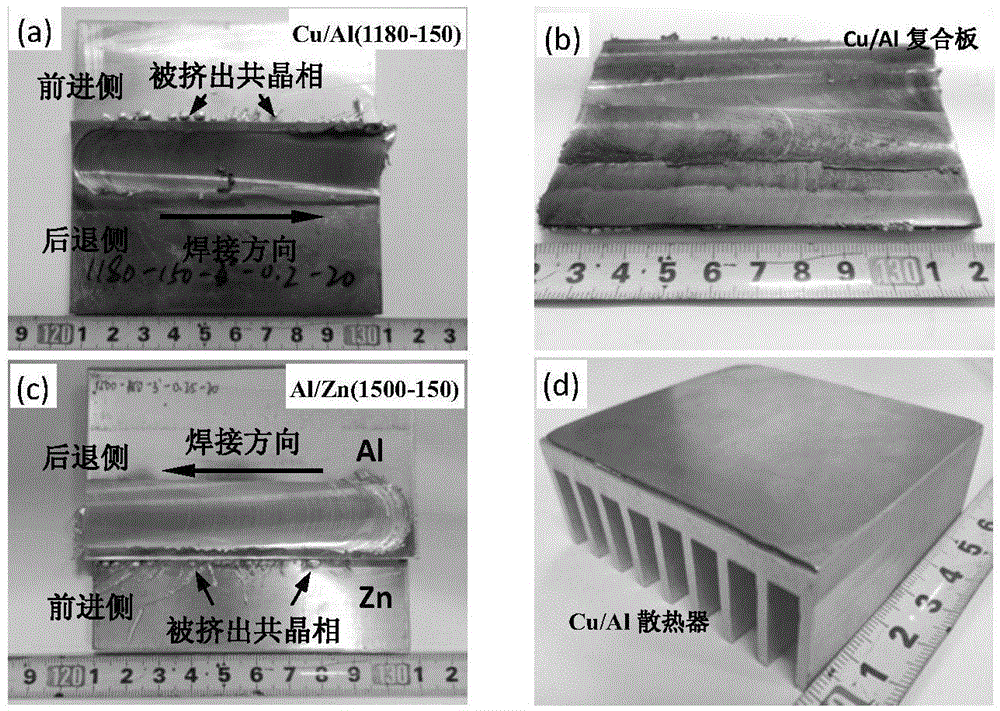

[0057] Surface forming quality: under the conditions of welding process parameters (1180-150-3°-0.2-20) the joint appear...

Embodiment 2

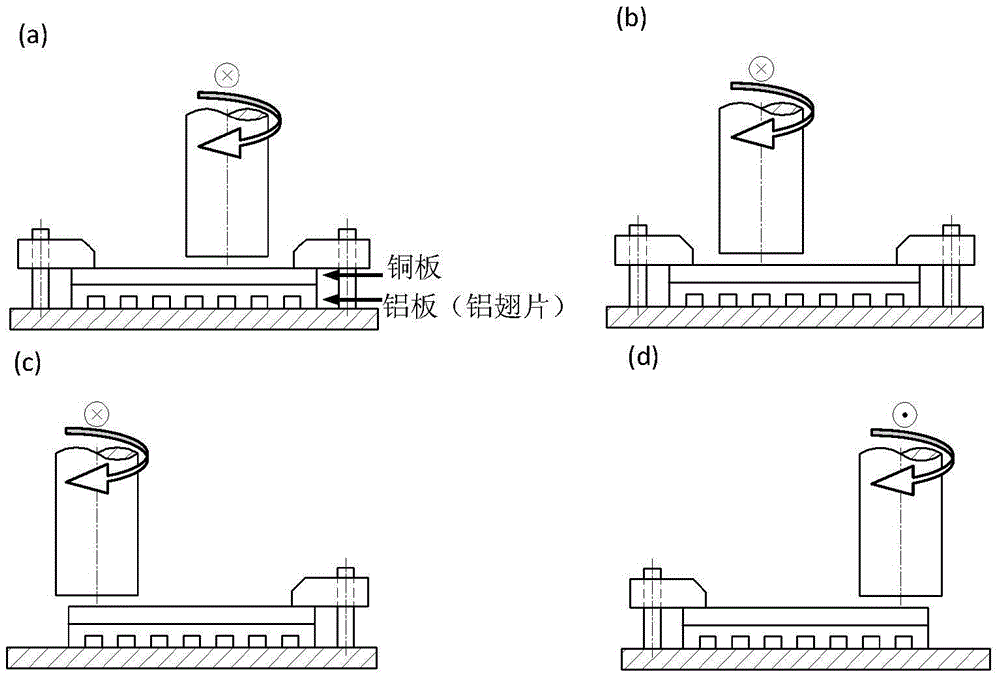

[0062] Example 2: Preparation of Cu / Al composite plate by multi-pass friction stir eutectic reaction welding

[0063] image 3 (b) Untreated Cu / Al composite plate prepared by friction stir eutectic reaction welding technique. Commercially available pure copper plate T2 and pure aluminum 1060 with a thickness of 2mm (measured 1.96mm) are selected as the parts to be welded, and the specifications are 100×60×2mm. The stirring head is a needleless stirring head with a diameter of D=20mm, and the material is 1Cr13 martensitic stainless steel. For the assembly method and welding process during welding, see figure 2 (a), (b), (c) and (d), the copper plate completely covers the aluminum plate, and the area of the overlapping area is 100×60mm. When welding, the welded area is on the retreat side, and the unwelded area is on the On the advancing side, start the first weld seam from ~5mm from the pressure block (see figure 2 (a)), perform the second welding in the direction of th...

Embodiment 3

[0066] Example 3: Fabrication of Al / Zn joints by friction stir eutectic reaction welding

[0067] Commercially available pure aluminum 1060 with a thickness of 2mm (measured 1.96mm) and pure zinc with a thickness of 3mm are selected as the parts to be welded, and the specifications are 100×60×2mm and 100×60×3mm respectively. The material of the stirring head is 1Cr13 martensitic stainless steel, the diameter D=20mm, and no needle. The assembly method of the lap joint is adopted, the area of the lap area is 100×25mm, the upper end is an aluminum plate, and the lower end is a zinc plate, such as figure 1 shown. The welding process parameters are shown in Table 3.

[0068] Table 3. Process parameters of Al / Zn joints prepared by friction stir eutectic reaction welding

[0069]

[0070] See image 3 (c): The joint is formed smoothly, without obvious flash and burrs, and there are extruded eutectic liquid phase solidified metal balls on the edge of the overlapping area, ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com