Method for quickly starting short-cut nitrification and denitrification of ammonia-containing wastewater

A short-range nitrification and quick-start technology, which is applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of low removal rate, long start-up time, and ineffective treatment of low COD and high ammonia nitrogen Wastewater and other problems, to achieve the effect of high wastewater treatment efficiency, efficient removal, and long-term stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation of embodiment 1 ammonia oxidizing bacteria growth promoter

[0027] The preparation method of the ammonia oxidizing bacteria growth promoter of the present invention is as follows: (1) prepare the metal salt solution according to the following composition and parts by weight: the metal salt is 40 to 100 parts by weight, preferably 50 to 80 parts by weight, and the metal salt is Calcium salt, ferrous salt and copper salt, Ca in metal salt 2+ , Fe 2+ and Cu 2+ The molar configuration ratio is (5~15):(1~8):(0.5~5), preferably (8~12):(2~6):(1~4); (2) combine 10~40 Parts by weight, preferably 20 to 30 parts by weight Na 2 SO 3 (3) Add 5-30 parts by weight, preferably 10-20 parts by weight, of polyamines and 0.05-1.5 parts by weight, preferably 0.1-1.0 parts by weight, of inorganic acid hydroxylamine before use into the metal salt solution.

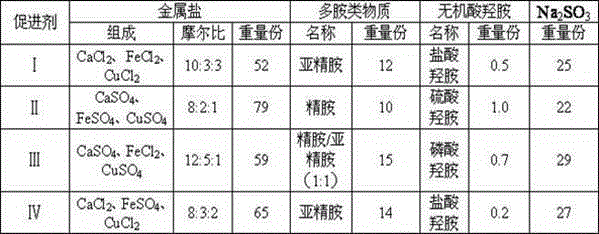

[0028] Four types of accelerators were prepared according to the ratio and formula of the accelerators in Table 1...

Embodiment 2

[0031] The preparation of embodiment 2 denitrification bacteria agent

[0032] (1) Arthrobacter FDN-1 and Flavobacterium waterii FDN-2 were respectively inoculated on beef extract peptone solid medium and activated in a constant temperature incubator at a temperature of 30°C. The medium formula was: beef extract: 5g / L , Peptone: 10g / L, NaNO 2 : 1g / L, add 2.0% agar.

[0033] (2) Scrape a ring of solid bacteria with an inoculation loop to inoculate in the beef extract peptone liquid culture solution, and culture under aerobic conditions at a temperature of 25~35°C and 150~240rpm for 1~3 days until the logarithmic growth phase, and obtain a liquid Bacteria agent seed solution; medium formula: beef extract: 5g / L, peptone: 10g / L, NaNO 2 : 1g / L.

[0034] (3) The above-mentioned Arthrobacter FDN-1 and Flavobacterium waterii FDN-2 seed liquids were combined according to the two ratios of 1:1 and 1:2 to carry out amplified culture in a reactor with a good stirring system, and the T...

Embodiment 3

[0036] The start-up effect of embodiment 3 different accelerants and different bacterial agents

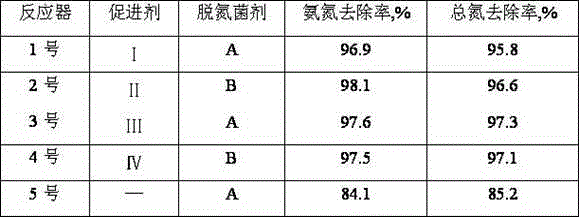

[0037] Take five reactors No. 1 to No. 5 with the same volume, inoculate the remaining activated sludge of a sewage treatment plant according to the MLSS after inoculation of 2.0g / L, and dilute the high-ammonia wastewater from a catalyst plant to 250mg / L as the reactor For water intake, the pH is controlled at 8.2; the temperature is controlled at 30°C; the dissolved oxygen concentration is 3.0~3.5mg / L. Water is fed intermittently first, while the water is fed, according to the accelerator concentration 2mg / L in the sewage, the accelerator of embodiment 1 is added respectively to the No. 1-4 reactor, the ventilation is stopped after 24 hours of reaction, and the supernatant is removed after natural settlement. Leave the bacteria, and then add new ammonia-containing wastewater to the reactor. When the ammonia nitrogen removal rate reaches 80%, reduce the dilution factor of the orig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com