Novel integral softening and treating device for industrial wastewater with high salt content

A technology for industrial wastewater and softening treatment, which is applied in the field of water treatment and can solve the problems of large consumption of chemicals, large floor space, and difficulty in controlling the dosage of chemicals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

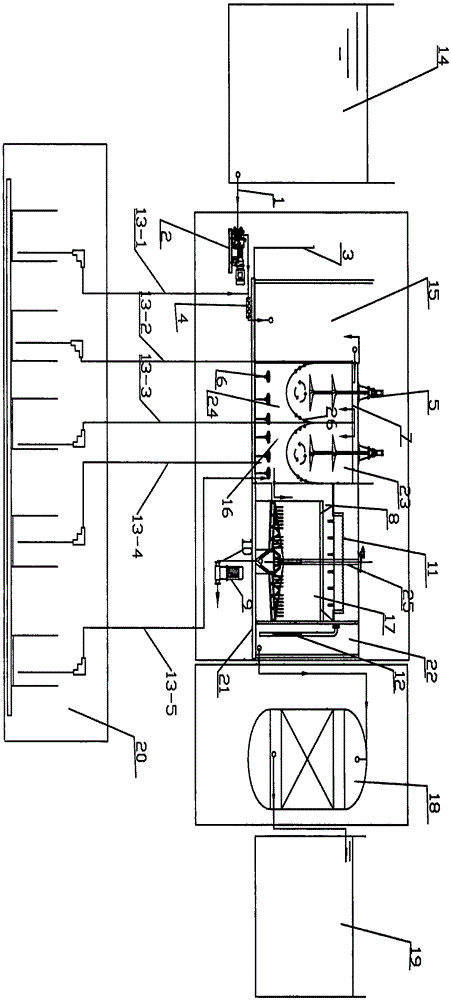

[0045] Such as figure 1 As shown, the high-salt industrial wastewater of the present invention enters the reaction tank 15 from the high-salt wastewater pool 14 through the pipeline mixer 4, and before entering the reaction tank 15, the dosing pipe 13-1 is added with sodium hydroxide and mixed by the pipeline 4 mixing, along with the rise of the water level, sodium carbonate is added through the dosing pipe 13-2 above the reaction tank 15, and then the calcium and magnesium in the water generate magnesium hydroxide and calcium carbonate precipitation by reacting with sodium hydroxide and sodium carbonate, The reaction pool 15 enters the coagulation pool 23 evenly through the water distribution channel 7, and the polyferric sulfate coagulant is added to the water distribution channel 7 through the dosing pipe 13-3, and the mixer 5 slowly stirs and enters the flocculation pool 24 through the outlet hole 26. The flocculation tank 24 is filled with polyacrylamide flocculant and hy...

Embodiment 2

[0047] Such as figure 1 As shown, taking the high-hardness saline wastewater treatment project in the industrial park as an example, the average concentration of each pollutant is: total hardness (in terms of CaCO 3 Calculated) is 3500mg / L, total alkalinity (as CaCO 3 Total) is 300mg / L, TDS is 7800mg / L, COD is 200mg / L, ammonia nitrogen is 12mg / L. The influent flow rate is 400m3 / h.

[0048] Add 32% liquid caustic soda through the dosing pipe 13-1 on the water inlet pipe of the pipeline mixer 4, and the dosage is 3500~3900g / T, add sodium carbonate through the dosing pipe 13-2 above the reaction tank 15, and the sodium carbonate is added The dosage is 2000-2300g / T, and the reaction time is 3-4h; the polyferric sulfate coagulant is added to the distribution channel 7 through the dosing pipe 13-3, and the dosage of the coagulant is 45-65g / T. Stirring speed is 80-120r / min, polyacrylamide flocculant and hydrochloric acid are added to the flocculation tank 24 through dosing pipes 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total hardness | aaaaa | aaaaa |

| Total alkalinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com