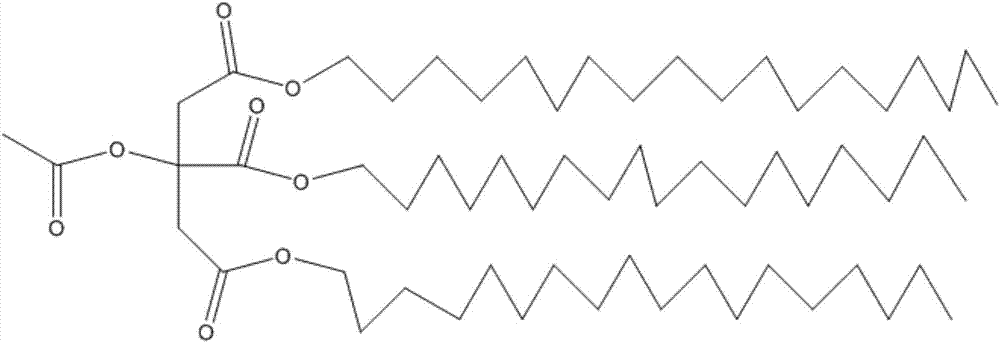

A kind of preparation method of acetyl citrate tri(stearyl alcohol) ester

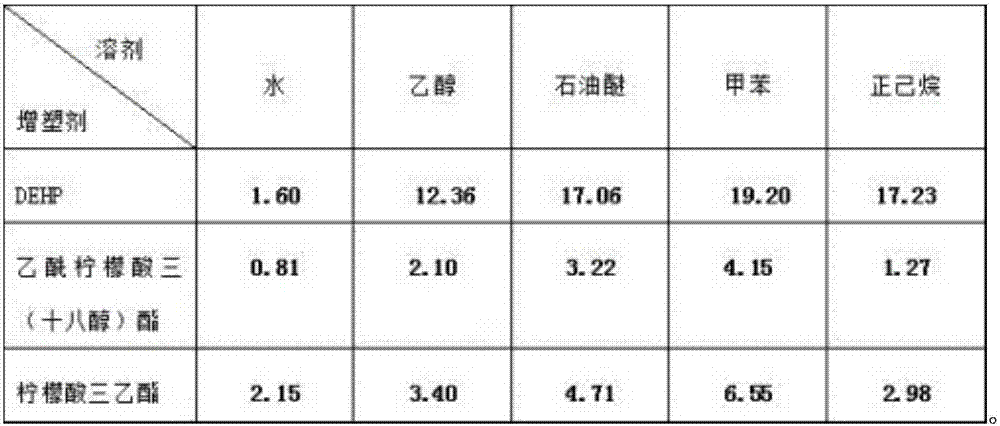

A technology of octadecanol and acetyl chloride, applied in the field of acetyl citrate triester and its synthesis, and the catalytic synthesis of medicinal acetyl citrate triester with mesoporous molecular sieve supported heteropoly acid, can solve the problem of poor catalyst reusability and anti-migration. It can improve the extraction resistance and migration resistance, increase the molecular weight, and have strong thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Phosphotungstic heteropolyacid is dissolved in twice-distilled water, injected into a stainless steel high-pressure autoclave with a polytetrafluoroethylene lining, weighs the molecular sieve MCM-41 carrier that has been baked, and pours it into the heteropolyacid solution, Add 4% molecular sieve quality sodium carbonate solid, stir to form a thick pack, treat in an oven at 110°C for 20h, filter after cooling, heat and dry to obtain the required supported heteropolyacid catalyst;

[0026] (2) Add a quantitative amount of 200g stearyl alcohol and 20g citric acid to a reactor equipped with a mechanical stirrer, a thermometer, and an oil-water separator, heat to melt the raw materials, add 0.5g catalyst and continue to heat up to 60°C, add 300ml n-Butanol, heated to reflux until the reaction is complete, and the excess stearyl alcohol is evaporated under reduced pressure;

[0027] (3) Add 10g of acetyl chloride in step (2), filter after fully reacting, reclaim the cata...

Embodiment 2

[0030] (1) Silicon-tungsten-molybdenum heteropolyacid is dissolved in double distilled water, injected into a stainless steel high-pressure autoclave with PTFE lining, weighed the baked molecular sieve MCM-41 carrier, and poured into the heteropolyacid solution , add 6% molecular sieve quality sodium carbonate solid, stir to form a thick pack, treat in an oven at 110°C for 20h, filter after cooling, heat and dry to obtain the required supported heteropolyacid catalyst;

[0031] (2) Add a quantitative amount of 300g stearyl alcohol and 25g citric acid to a reactor equipped with a mechanical stirrer, a thermometer, and an oil-water separator, heat to melt the raw materials, add 0.5g catalyst and continue to heat up to 70°C, add 300ml n-Butanol, heated to reflux until the reaction is complete, and the excess stearyl alcohol is evaporated under reduced pressure;

[0032] (3) Add 15g acetyl chloride in step (2), filter after fully reacting, reclaim catalyst, residue is washed 4 tim...

Embodiment 3

[0035] (1) Phosphotungstomolybdenum heteropolyacid is dissolved in twice distilled water, injected into a stainless steel high-pressure autoclave with a polytetrafluoroethylene lining, weighed the baked molecular sieve MCM-41 carrier, and added 6% molecular sieve quality carbonic acid Sodium solid, poured into the heteropoly acid solution, stirred to form a thick pack, treated in an oven at 110°C for 24 hours, filtered after cooling, heated and dried to obtain the required supported heteropoly acid catalyst;

[0036] (2) Add a quantitative amount of 400g stearyl alcohol and 30g citric acid to a reactor equipped with a mechanical stirrer, a thermometer, and an oil-water separator, heat to melt the raw materials, add 0.5g catalyst and continue to heat up to 60°C, add 300ml n-Butanol, heated to reflux until the reaction is complete, and the excess stearyl alcohol is evaporated under reduced pressure;

[0037] (3) Add 10g acetyl chloride in step (2), filter after fully reacting, r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| load ratio | aaaaa | aaaaa |

| load ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com