Method for preparing biuret polyisocyanates

A technology for polyisocyanates and diisocyanates is applied in the field of preparing biuret polyisocyanates, which can solve the problems of energy waste, poor adjustability and high product viscosity, and achieve the effects of improving operation safety, avoiding energy consumption and reducing product viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

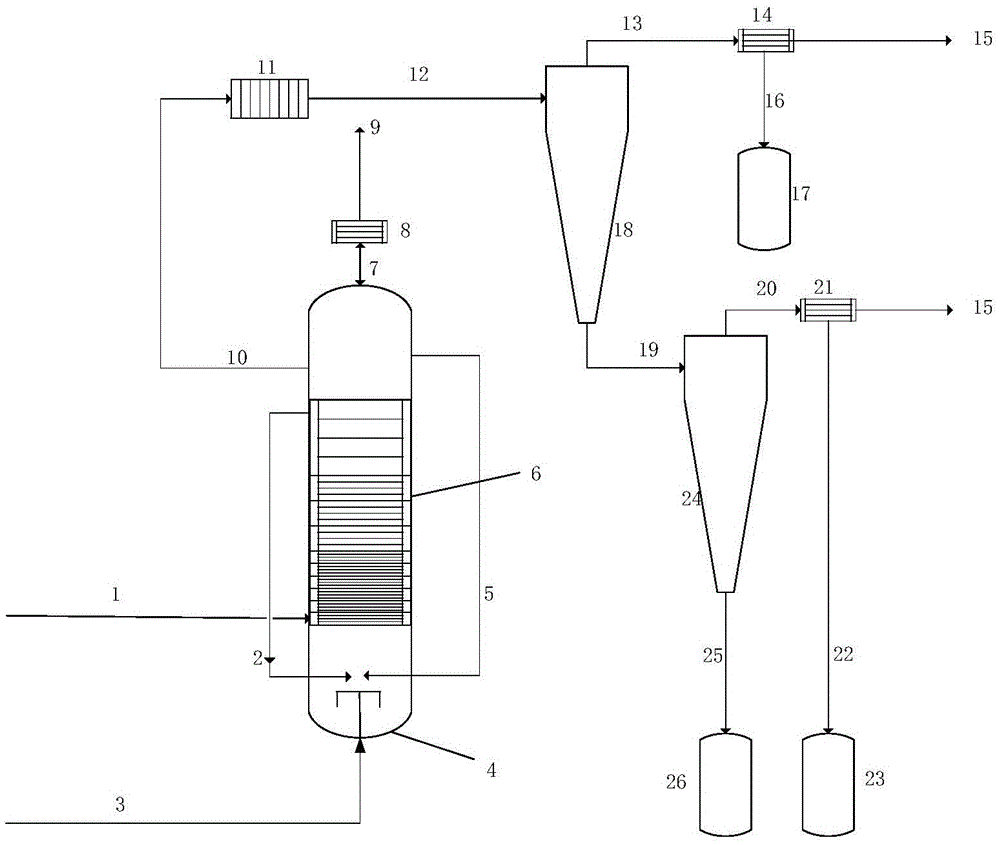

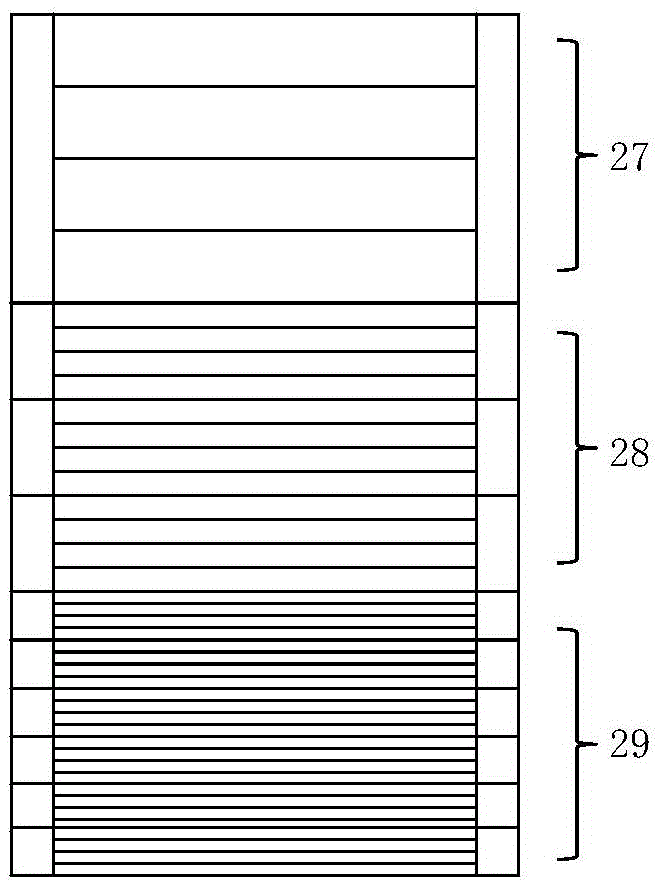

[0056] Prepare the mixed solution of hexamethylene diisocyanate and catalyst diethyl phosphate and piperazine, the temperature is 25 ℃, wherein the consumption of diethyl phosphate and piperazine is 0.6wt% based on hexamethylene diisocyanate, wherein phosphoric acid The mass ratio of diethyl ester and piperazine is 5:1, and the mixed solution is continuously pumped into the built-in heat exchanger 6 with a flow rate of 110kg / h, and then preheated by the built-in heat exchanger 6 to obtain preheated isocyanate Raw material 2, the reaction temperature in the bubble column reactor is 130°C, the mass ratio of water vapor and nitrogen is 1:1, the flow rate is 3.6kg / h, the temperature of the water vapor and nitrogen mixer is 165°C; the circulating reaction solution 5 The ratio of raw material liquid (raw material isocyanate and catalyst mixed raw material 1 or preheated isocyanate raw material 2) is 10:1, and the average residence time of the reaction liquid in the bubble column reac...

Embodiment 2

[0058] Prepare a mixed solution of hexamethylene diisocyanate and catalyst diethyl phosphate and triethylene diamine at a temperature of 25°C, wherein the amount of diethyl phosphate and triethylene diamine is 1 wt% of the mass of hexamethylene diisocyanate , wherein the mass ratio of diethyl phosphate and triethylenediamine is 9:1, the mixed solution is continuously pumped into the built-in heat exchanger 6, the flow rate is 110kg / h, and then preheated by the built-in heat exchanger 6 to obtain For the preheated isocyanate raw material 2, the reaction temperature in the bubble column reactor is 110°C, the mass ratio of water vapor to nitrogen is 1:1, the flow rate is 3.6kg / h, and the temperature of the water vapor and nitrogen mixer is 105°C ; The ratio of circulating reaction liquid 5 to raw material liquid (raw material isocyanate and catalyst mixed raw material 1 or preheated isocyanate raw material 2) is 2:1, and the average residence time of the reaction liquid in the bub...

Embodiment 3

[0060] Prepare a mixed solution of hexamethylene diisocyanate and catalyst diethyl phosphate and imidazole at a temperature of 25°C, wherein the amount of diethyl phosphate and imidazole is 1.05wt% of the mass of hexamethylene diisocyanate, wherein diethyl phosphate The mass ratio of ester and imidazole is 20:1, and the mixed solution is continuously pumped into the built-in heat exchanger 6 with a flow rate of 110kg / h, and then the preheated isocyanate raw material 2 is obtained after being preheated by the built-in heat exchanger 6, The reaction temperature in the bubble column reactor is 100°C, the mass ratio of water vapor and nitrogen is 1:1, the flow rate is 3.6kg / h, the temperature of the water vapor and nitrogen mixer is 100°C; the circulating reaction liquid 5 and the raw material liquid (The ratio of raw material isocyanate and catalyst mixed raw material 1 or preheated isocyanate raw material 2) is 1:5, the average residence time of the reaction liquid in the bubble ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com