Method for synthesizing alpha-aryl ethyl phosphonate

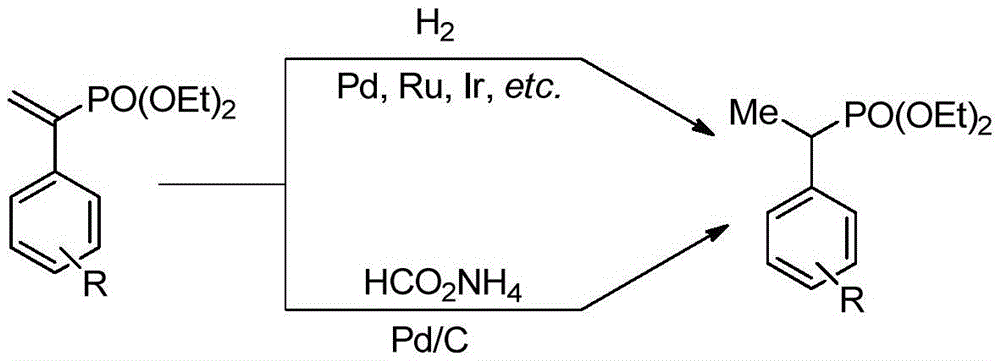

A technology of aryl ethyl phosphonate and aryl vinyl phosphonate, which is applied in the field of synthesizing α-aryl ethyl phosphonate, can solve the problems of heavy metal residues in hydrogenation products, and achieve strong functional group compatibility and reaction Mild conditions and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

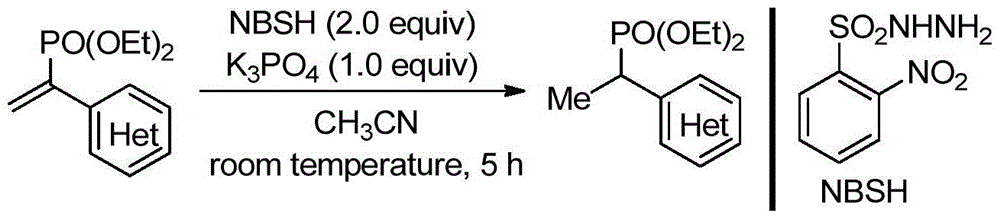

Method used

Image

Examples

Embodiment 1

[0020] Add 0.3mmol of diethyl α-(4-chlorophenyl)vinylphosphonate, 0.6mmol of o-nitrobenzenesulfonyl hydrazide, and 0.3mmol of potassium carbonate to a Schlenk reaction tube (10mL), vacuumize and release N 2 Cycle three times. in N 2 Under protection, add 2.0 mL of anhydrous acetonitrile, stir at room temperature for 5 h; after TLC confirms that the reaction is complete, add 5 mL of water to the reaction system, extract 3 times with 30 mL of ethyl acetate (10 mL*3), combine the organic phases, and wash with anhydrous sulfuric acid Sodium drying; then filter to remove sodium sulfate, and distill through a rotary evaporator to obtain an organic primary product. Then, the above-mentioned organic primary product is separated by column chromatography with a mixture of petroleum ether and ethyl acetate with a volume ratio of 1:1 as an eluent, and finally α-(4-chlorophenyl) ethyl acetate is obtained by distillation with a rotary evaporator. Diethyl phosphonate 80.3 mg, yield 97%. T...

Embodiment 2

[0023] Add 0.3mmol of diethyl α-(3-chlorophenyl)vinylphosphonate, 0.6mmol of o-nitrobenzenesulfonyl hydrazide, and 0.3mmol of potassium phosphate into a Schlenk reaction tube (10mL). 2 Cycle three times. in N 2 Under protection, add 2.0 mL of anhydrous acetonitrile, stir at room temperature for 5 h; after TLC confirms that the reaction is complete, add 5 mL of water to the reaction system, extract 3 times with 30 mL of ethyl acetate (10 mL*3), combine the organic phases, and wash with anhydrous sulfuric acid Sodium drying; then filter to remove sodium sulfate, and distill through a rotary evaporator to obtain an organic primary product. Then, the above-mentioned organic primary product is separated by column chromatography with a mixture of petroleum ether and ethyl acetate with a volume ratio of 1:1 as an eluent, and finally α-(3-chlorophenyl) ethyl acetate is obtained by distillation with a rotary evaporator. Diethyl phosphonate 74.5 mg, yield 90%. The analysis data is as...

Embodiment 3

[0026] Add 0.3mmol of diethyl α-(4-methylphenyl)vinylphosphonate, 0.6mmol of o-nitrobenzenesulfonyl hydrazide, and 0.3mmol of potassium phosphate into a Schlenk reaction tube (10mL), vacuumize and release N 2 Cycle three times. in N 2 Under protection, add 2.0 mL of anhydrous acetonitrile, stir at room temperature for 5 h; after TLC confirms that the reaction is complete, add 5 mL of water to the reaction system, extract 3 times with 30 mL of ethyl acetate (10 mL*3), combine the organic phases, and wash with anhydrous sulfuric acid Sodium drying; then filter to remove sodium sulfate, and distill through a rotary evaporator to obtain an organic primary product. Then the above-mentioned organic primary product is separated by column chromatography with a mixture of petroleum ether and ethyl acetate with a volume ratio of 1:1 as an eluent, and finally α-(4-methylphenyl) is obtained by distillation with a rotary evaporator. Diethyl ethylphosphonate 76.0 mg, yield 99%. The analy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com