Method for preparing gas energy by utilizing chlorine-containing plastic and carrying out harmless treatment on chromium slag at same time

A technology of energy gas and chromium slag, which is applied in the direction of chloride preparation, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of long reaction cycle, HCl is not easy to volatilize, and Cl pollution, so as to achieve harmlessness and avoid Effect of air pressure control and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

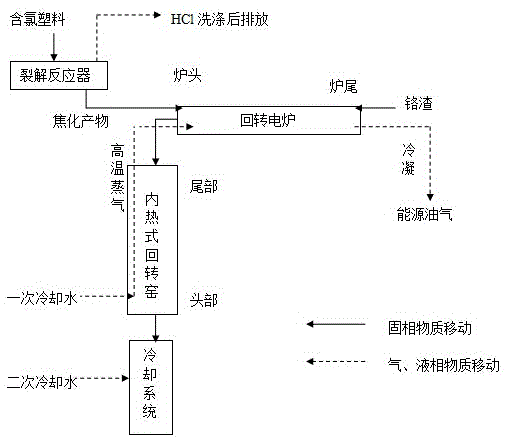

[0028] 1. After the chromium slag is ground to <2mm, it is transported to the tail of the rotary electric furnace through the screw feeder, and finally transported to the furnace head. Heating by an electric furnace keeps the temperature of the chromium slag at the furnace head stable at 800-1000°C. After being discharged from the furnace head, the chromium slag enters the internal heating rotary kiln head, and then is transported to the kiln tail;

[0029] 2. The chlorine-containing plastics are pyrolyzed in a pyrolysis reactor at 250-350°C, and the HCl produced by the pyrolysis enters the washing tower and is discharged. The solid-phase coking products produced by the cracking are then sent to the head of the rotary electric furnace and mixed with high-temperature steam and chromium slag. During this process, the plastic coking products are further cracked to generate cracking gas; the mixed gas of high-temperature steam and plastic cracking gas is rotating The electric f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com