Method for producing butanol by high-temperature enzymolysis and fermentation of lignocellulose

A lignocellulose, high-temperature enzymatic hydrolysis technology, applied in the field of lignocellulose high-temperature enzymatic hydrolysis and fermentation to produce butanol, can solve the problems that are far from industrialization and the immature temperature-resistant cellulase industry, and achieve increased temperature, The effect of reducing the cost of enzymes and improving the ability to withstand high temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The lignocellulosic raw material used in the embodiment of the present invention is dry corn stalk, wherein 38.2wt% of cellulose, 22.1wt% of hemicellulose, 20.2wt% of lignin, and 3.9wt% of ash are pulverized with a pulverizer until the particle size is 1- 5mm. Dilute acid steam explosion was used for pretreatment, the reaction temperature was 190°C, the reaction time was 5min, the solid-liquid ratio was 1:2, and the concentration of dilute sulfuric acid was 2.0wt%. After coming out from the steam explosion device, adjust the pH with NaOH to be 5.0, wherein the dry matter concentration is 32wt%, the cellulose content in the dry matter is 40wt%, the xylose content in the dry matter is 20.8%, and the pretreatment dry matter recovery rate is 96wt%.

[0030] The seed liquid medium is a conventional medium for butanol fermentation strains, such as P2 and RCM, etc., and is sterilized at 115°C for 30 minutes for later use. The preparation of the seed solution is divided into t...

Embodiment 2

[0040] The method for producing butanol by high-temperature enzymatic hydrolysis and fermentation of lignocellulose of the present invention comprises the following steps:

[0041] (1) Combined pretreatment of lignocellulosic raw material corn stalks and corn stalks with dilute acid steam explosion to obtain pretreated raw materials;

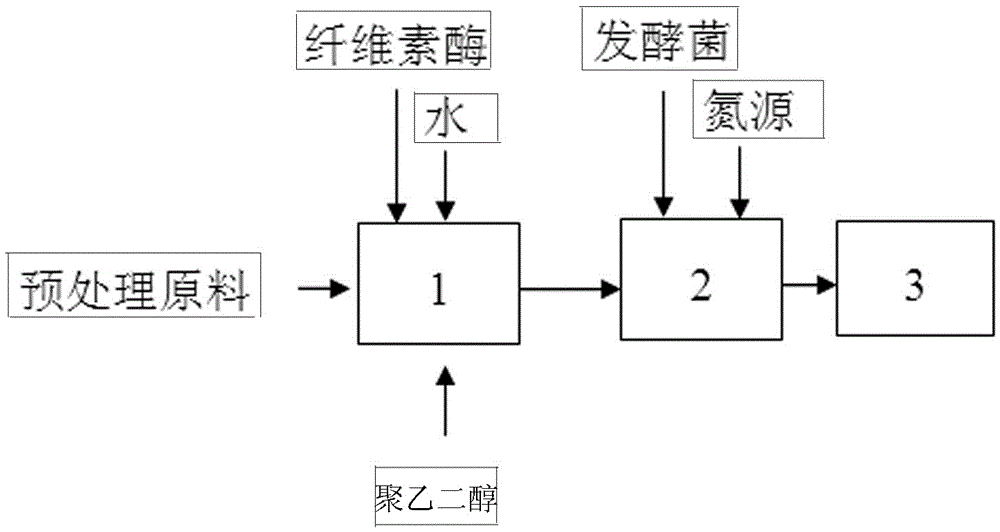

[0042] (2) Add the pretreated raw materials, cellulase, water and polyethylene glycol into the enzymolysis tank for preenzymolysis, and control the dry matter concentration of the enzymolysis system to 5wt%; control the enzymolysis time to 8h; preenzyme The pH of hydrolysis is 4.5; the temperature of pre-enzymolysis is 62 ℃; the addition amount of polyethylene glycol is 0.02g / L; the addition amount of described cellulase makes the ratio of cellulase and cellulose in the pretreatment raw material be 5IU / g cellulose;

[0043] (3) After the pre-enzymolysis, the feed liquid is poured into the fermenter, and the butanol fermentation strain is added ...

Embodiment 3

[0046] The method for producing butanol by high-temperature enzymatic hydrolysis and fermentation of lignocellulose of the present invention comprises the following steps:

[0047] (1) Combined pretreatment of lignocellulosic raw material corn stalks and corn stalks with dilute acid steam explosion to obtain pretreated raw materials;

[0048] (2) Add pretreated raw materials, cellulase, water and polyethylene glycol into the enzymolysis tank for preenzymolysis, and control the dry matter concentration of the enzymolysis system to 15wt%; control the enzymolysis time to 48h; preenzyme The pH of hydrolysis is 5.5; the temperature of pre-enzymolysis is 62 ℃; the addition amount of polyethylene glycol is 0.20g / L; the addition amount of described cellulase makes the ratio of cellulase and cellulose in pretreatment raw material be 25IU / g cellulose;

[0049] (3) After the pre-enzymolysis, the feed liquid is poured into the fermenter, and the butanol fermentation strain is added to ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com