Metal oxide thin film transistor and preparation method therefor, array substrate and display apparatus

A technology of oxide thin film and transistor, which is applied in the direction of transistor, semiconductor/solid-state device manufacturing, electric solid-state device, etc., can solve the problems of etching method preparation, etc., and achieve the effect of low cost, simple preparation process and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

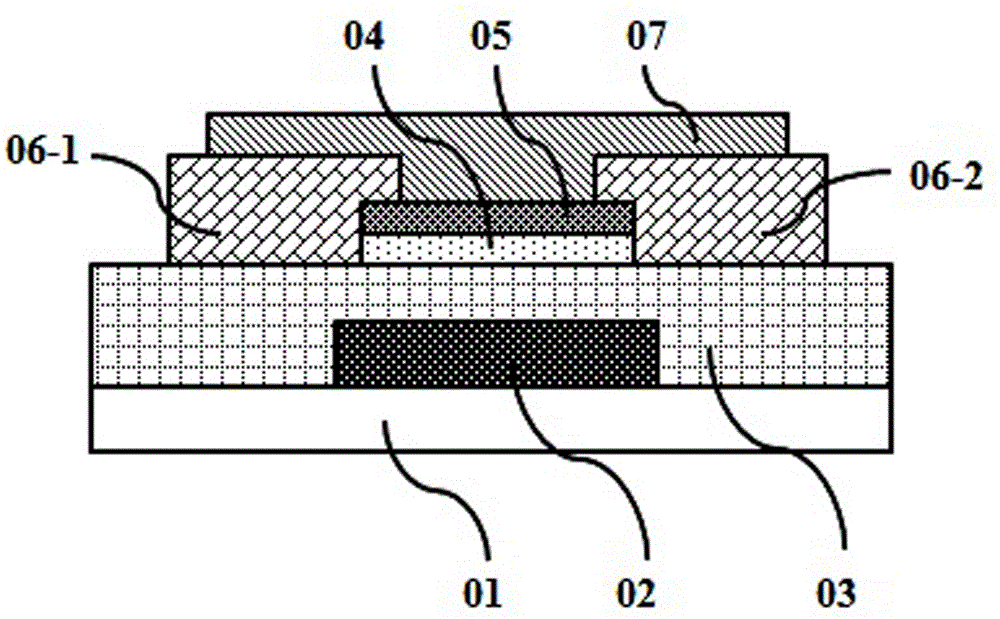

[0034] A metal oxide thin film transistor, such as figure 1 As shown, it includes a gate 02 disposed on a substrate 01, a gate insulating layer 03 covering the gate 02, a semiconductor active layer 04 disposed above the gate insulating layer 03, an active layer protection layer 05, an active layer The source and drain electrodes on the protective layer (the source is marked with 06-1, the drain is marked with 06-2) and the passivation layer 07.

[0035] Among them, the active layer protective layer is (MO)x(SnO 2 )y film, where 0≤x<1, 0.4≤y≤1, and x+y=1, M is silicon, aluminum, gallium, magnesium, calcium, strontium, bismuth, tantalum, hafnium, zirconium, scandium, yttrium or A combination of one or two or more arbitrary elements in the lanthanide rare earth elements.

[0036] The thickness of the protective layer of the active layer is 1-30 nm, preferably 2-10 nm.

[0037] The active layer is a metal oxide semiconductor material, and the active layer can be composed of a s...

Embodiment 2

[0044] A method for preparing a metal oxide thin film transistor, which is used to prepare the metal oxide thin film transistor of Example 1. Such as Figure 2 to Figure 5 shown, including the following steps.

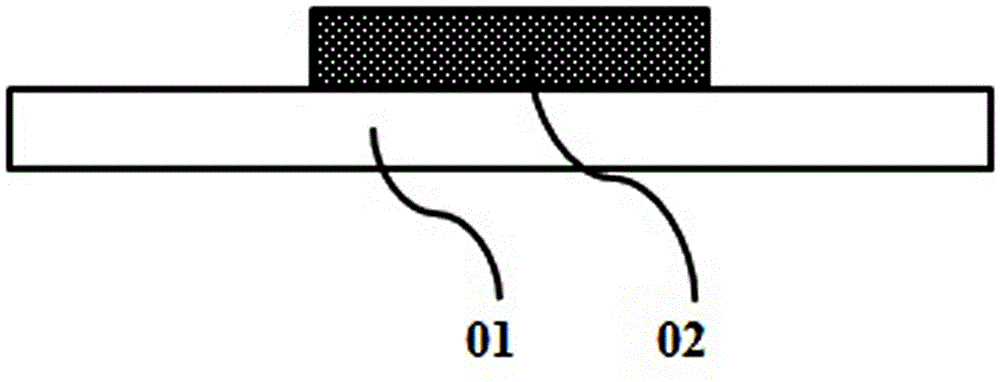

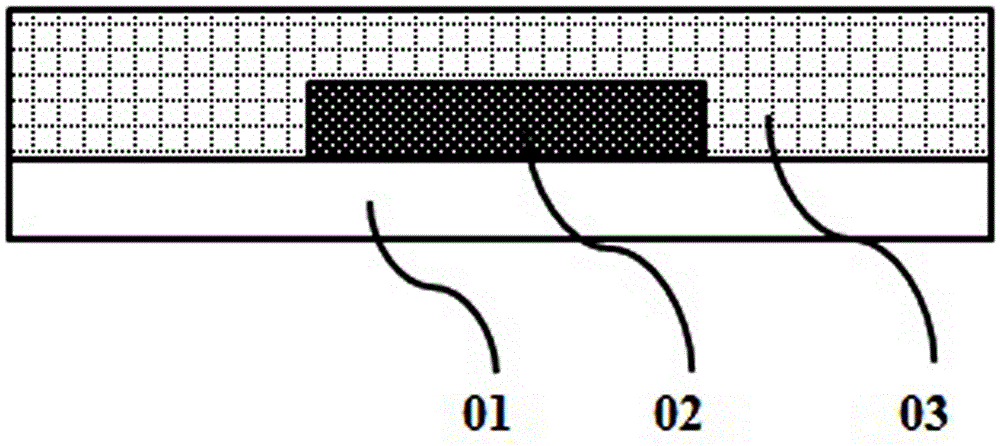

[0045] a) Deposit the gate metal layer film on the substrate 01 by magnetron sputtering, and form a pattern including the gate 02 of the thin film transistor and the gate line through a photolithography process, such as figure 2 shown.

[0046] It should be noted that the material of substrate 01 can be a hard glass substrate or a flexible substrate, such as: polyethylene naphthalate (PEN), polyethylene terephthalate (PET), polyamide imine (PI) or metal foil flexible substrate.

[0047] It should be noted that the substrate 01 may be a substrate without any film layer formed, such as white glass, or a substrate formed with other film layers or patterns, such as a buffer layer formed substrate. The photolithography process generally includes processes such as photore...

Embodiment 3

[0061] This embodiment provides a method for preparing a thin film transistor, which specifically includes the following steps:

[0062] a) A 200nm metal molybdenum thin film is deposited on the substrate by magnetron sputtering, and a gate metal layer is formed by a photolithography process.

[0063] b) Depositing a laminated gate insulating layer film by chemical vapor deposition, the gate insulating layer film is silicon nitride with a thickness of 250nm and silicon oxide with a thickness of 50nm, and the gate insulating layer is formed by a photolithography process.

[0064] c) After the gate insulating layer is completed, the active layer and the active layer protection layer are sequentially deposited by magnetron sputtering deposition method, wherein the active layer is a 50nm thick indium gallium zinc oxide (IGZO) film, and the active layer protection layer is The layer is a 5nm thick gallium tin oxide (GaSnO) film. Finally, the layer of the active layer and the prote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com