Long-life catalyst for synthesis of propylene carbonate and preparation method thereof

A technology of acrylate carbonate and catalyst, which is applied in the field of long-life catalyst and its preparation, can solve the problems of difficult separation of homogeneous catalyst, easy loss of active components, loss of active components, etc., and achieves low loss rate, long catalyst life, The effect of high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

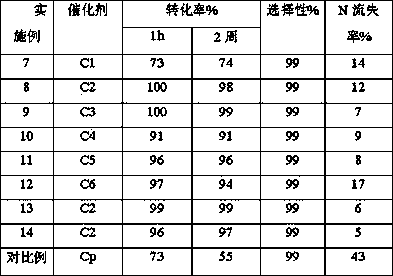

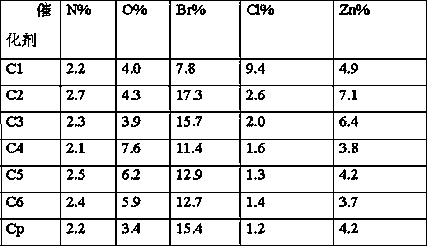

Examples

Embodiment 1

[0034] (1) 11 g of imidazo[1,2-a]pyrazine and 19 g of 1,2-dibromoethane were dissolved in 30 g of methanol, and refluxed at 50°C for 2 days. Then the product is concentrated by distillation to obtain an oily long-chain domidazole compound.

[0035] (2) Reflux 20 g of domisole compound and 40 g of chloromethyl polystyrene microspheres in 200 g of toluene for 2 days. After filtering, it was washed three times with toluene and propylene carbonate respectively, and then dried in vacuum at 70° C. for 24 hours to obtain active component A1.

[0036] (3) Grinding and mixing 20 grams of active component A with 10 grams of zinc chloride, 20 grams of resorcinol formaldehyde resin, and 2 grams of urotropine, and crushing them into powders below 120 mesh. The powder is compressed into tablets, the pressure of the compression molding is 12 MPa, and the time of holding under pressure is 3 minutes. Active precursor B1 was prepared.

[0037] (4) The active precursor B was heated at 180 °C ...

Embodiment 2

[0040] (1) 11 g of imidazo[1,2-a]pyrazine and 19 g of 1,2-dibromoethane were dissolved in 30 g of methanol, and refluxed at 50°C for 4 days. Then the product is concentrated by distillation to obtain an oily long-chain domidazole compound.

[0041] (2) Reflux 20 g of domidazole compound and 40 g of chloromethyl polystyrene microspheres in 200 g of toluene for 1 day. After filtration, it was washed three times with toluene and propylene carbonate respectively, and then dried in vacuum at 70° C. for 24 hours to obtain active component A2.

[0042] (3) Grind and mix 20 grams of active component A2 with 15 grams of zinc bromide, 20 grams of resorcinol formaldehyde resin, and 2 grams of urotropine, and grind them into powders below 120 mesh. The powder is compressed into tablets, the pressure of the compression molding is 12 MPa, and the time of holding under pressure is 3 minutes. Active precursor B2 was prepared.

[0043] (4) The active precursor B2 was heated at 180 °C for 2 ...

Embodiment 3

[0046] (1) 11 g of imidazo[1,2-a]pyrazine and 19 g of 1,2-dibromoethane were dissolved in 30 g of methanol, and refluxed at 50°C for 2 days. Then the product is concentrated by distillation to obtain an oily long-chain domidazole compound.

[0047] (2) Reflux 20 g of domidazole compound and 40 g of chloromethyl polystyrene microspheres in 200 g of toluene for 3 days. After filtering, it was washed three times with toluene and propylene carbonate respectively, and then dried under vacuum at 70°C for 24 hours to obtain active component A3.

[0048] (3) Grinding and mixing 20 grams of active component A3 with 30 grams of zinc bromide, 20 grams of resorcinol formaldehyde resin, and 2 grams of urotropine, and crushing them into powders below 120 mesh. The powder is compressed into tablets, the pressure of the compression molding is 12 MPa, and the time of holding under pressure is 3 minutes. Active precursor B3 was prepared.

[0049] (4) The active precursor B3 was heated at 180...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com