Production method of high-calcium-dissolution cucumber seed drink

A technology for cucumber seeds and beverages, which is applied in the field of preparation of high-calcium dissolution cucumber seed beverages, can solve the problems of low calcium solubility, difficulty in absorption, low acceptability of pharmaceutical preparations, and single calcium supplementation method, so as to improve the dissolution of calcium The effect of high efficiency and sensory stability, stable product appearance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preparation method of high calcium dissolved cucumber seed beverage, the method comprises the steps of:

[0035] 1) Cucumber seeds are selected as raw materials and washed after sorting. The cucumber seeds and seed skins are relatively soft without softening and shelling, which can reduce the process steps and reduce the loss of calcium during processing;

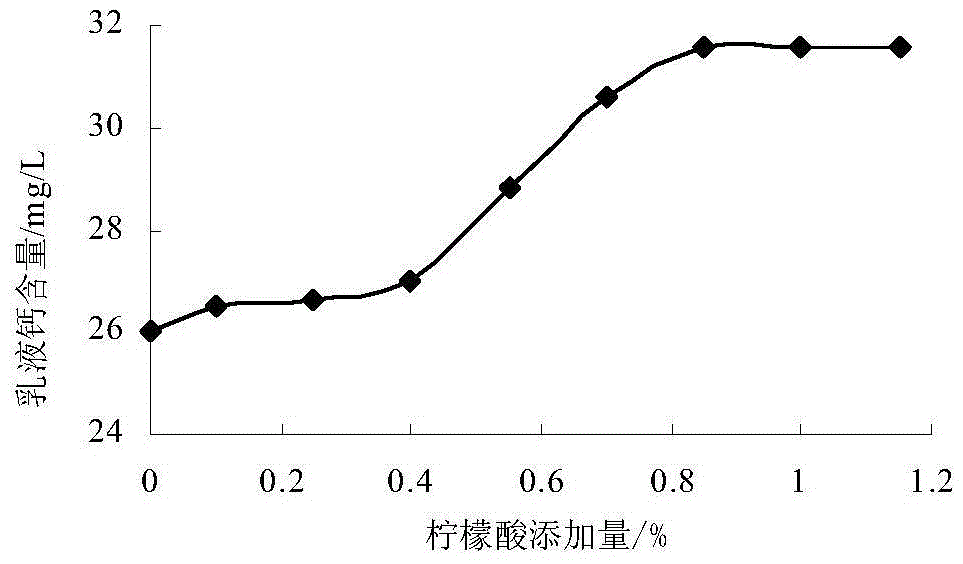

[0036] 2) To prepare acidified water, in order to eliminate the impact of water quality on the results, pure water is used, which is prepared by adding citric acid or lactic acid to the water, wherein the mass percentage concentration of citric acid in the acidified water is 0.85%-1%, lactic acid The mass percentage concentration in acidified water is 0.85%-1.15%.

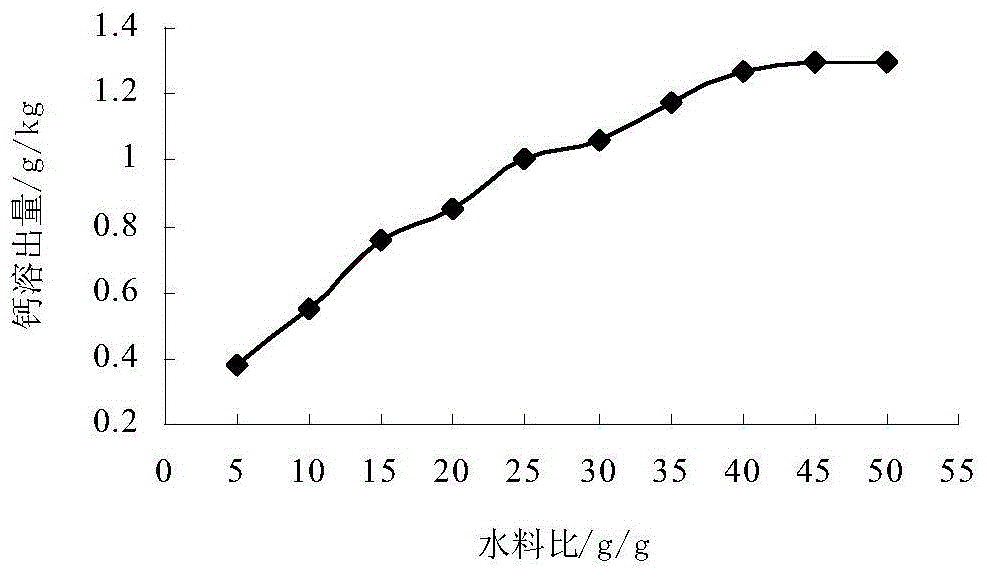

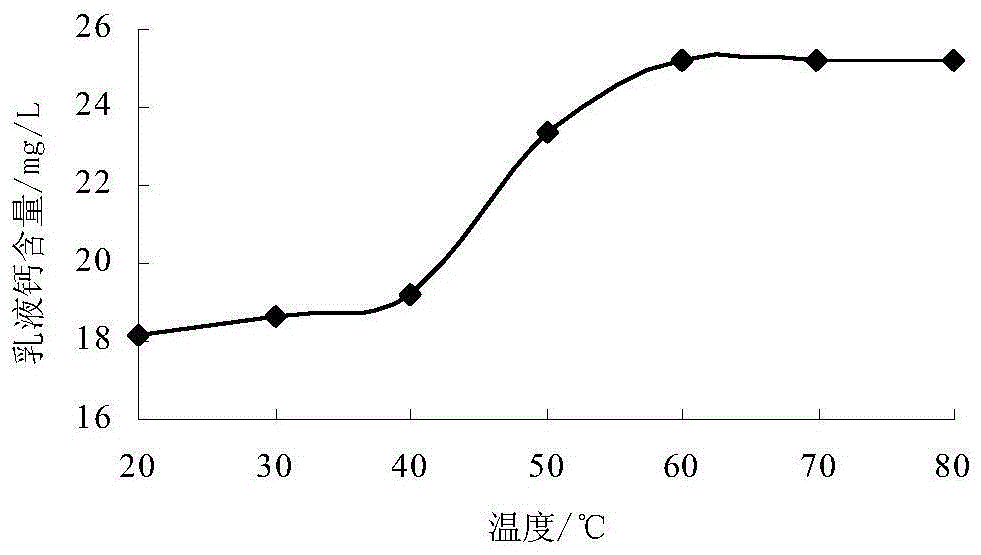

[0037] 3) Mix the cucumber seeds obtained in step 1) with acidified water, beat with a refiner, heat the slurry and keep it warm. Because the outer wall of cucumber seeds is covered with fiber components, the calcium components inside are not easy to d...

Embodiment 1

[0044] Select 20g of cucumber seeds and wash them for later use. Add citric acid to the purified water to a final concentration of 0.85% to prepare 1 L of acidified water. It should be noted that in order to eliminate the influence of water quality on the experimental results, pure water is used in this example, but not limited to pure water. Beat with a refiner. The refined mixture was heated to 60°C and kept for 30 minutes. The slurry is filtered with a 200 mesh sieve (or filter cloth).

[0045]Mix 0.2g of sucrose and 1g of compound thickening stabilizer (locust bean gum and sodium alginate are premixed at a weight ratio of 1:1) and add to the filtrate, and heat to 80°C while stirring until completely dissolved. Other sugars or sweeteners required for seasoning can be added sequentially as needed. The evenly prepared beverage slurry was homogenized 3 times with a colloid mill. The beverage slurry is filled into pre-washed glass bottles, pre-sealed, pasteurized, finally s...

Embodiment 2

[0048] Select 20g of cucumber seeds and wash them for later use. Add lactic acid to purified water to a final concentration of 1.15%, to prepare 1 L of acidified water. Beat with a refiner. The refined mixture was heated to 55°C and kept for 60 minutes. The slurry is filtered with a 200 mesh sieve (or filter cloth). Mix 0.2g of sugar and 1g of compound thickening stabilizer (locust bean gum and sodium alginate are premixed at a weight ratio of 1:1) and add to the filtrate, and heat to 80°C while stirring until completely dissolved. Other sugars or sweeteners required for seasoning can be added sequentially as needed. The evenly prepared beverage slurry was homogenized twice with a colloid mill. The beverage slurry is filled into pre-washed glass bottles, pre-sealed, pasteurized, finally sealed, cooled to room temperature, and then cooled to 4°C for storage. The calcium content in the cucumber seed emulsion can be increased from 18.2 mg / L to 30.2 mg / L after being treated b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com