Copper nickel-zinc oxide composite nanocrystalline photocatalyst and preparation method and application thereof

A technology of zinc oxide nanocrystals and photocatalysts, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high raw material costs and achieve short reaction times , controllable shape and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

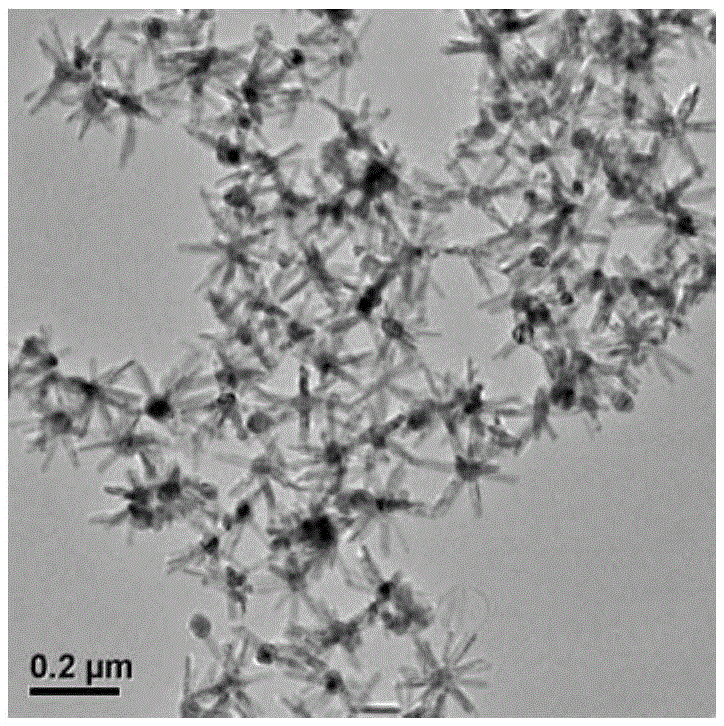

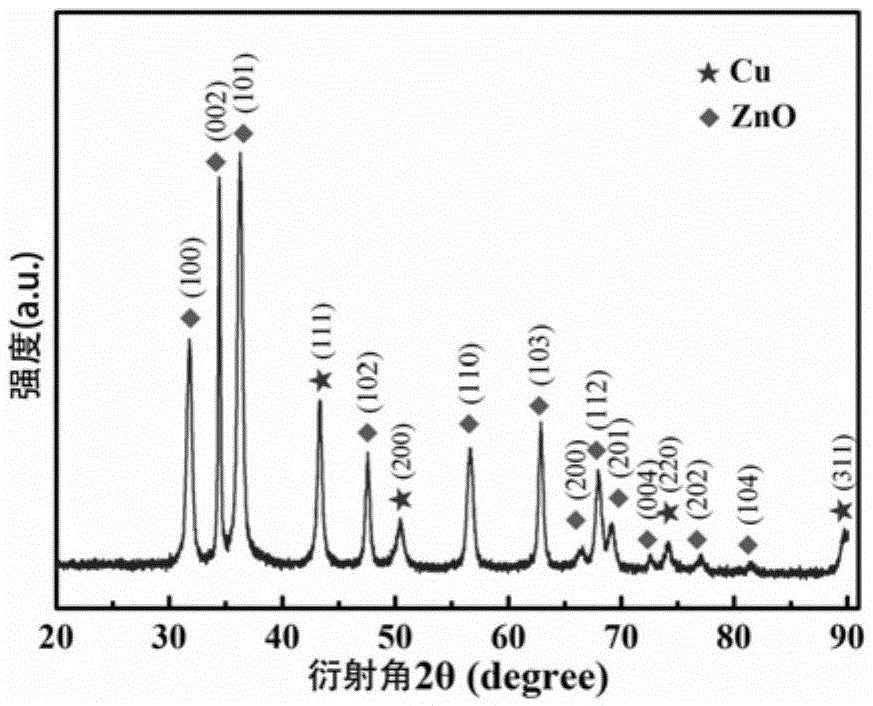

[0032] Add 0.2mmol copper acetylacetonate, 1.5mmol trioctylphosphine oxide, 4ml oleylamine, and 4ml benzyl alcohol into a four-neck flask, stir and mix under the protection of argon, then raise the temperature to 200°C, and keep it warm for 40min. In addition, add 0.15g of zinc acetate and 2ml of oleylamine into the three-necked flask, stir under the protection of argon until the mixture is uniform, keep the temperature at 80°C for about 20min, then suck the mixed solution with a syringe, and wait for the reaction in the four-necked flask After the solution was incubated for 40 minutes, it was immediately injected into the reaction solution in the four-necked bottle, and the whole injection process was about 30 seconds. After the injection was completed, the temperature was raised to 190°C and kept for 60 minutes. The reaction solution was naturally cooled to room temperature, ethanol was added to precipitate the product, and the reaction mother liquid was taken out by centrif...

Embodiment 2

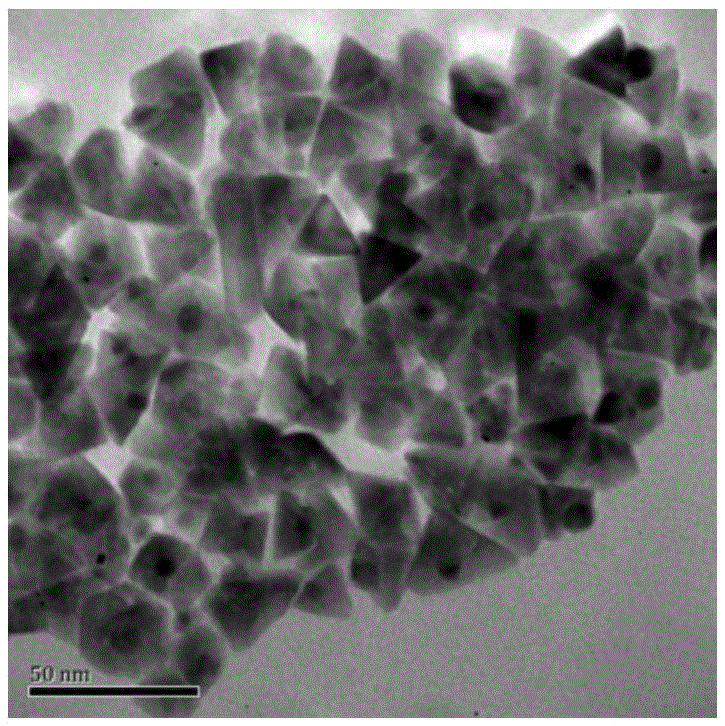

[0035] Add 0.15 mmol of copper acetylacetonate, 0.5 mmol of trioctylphosphine oxide and 7 ml of oleylamine into a four-neck flask, stir and mix under the protection of argon, then raise the temperature to 200°C and keep it warm for 30 minutes. In addition, add 0.35g of zinc stearate and 2ml of oleylamine into a three-necked bottle, stir under the protection of argon until the mixture is uniform, and keep the temperature at 80°C for about 10 minutes, then suck up the mixed solution with a syringe, and put it in the four-necked bottle Immediately after the reaction solution was incubated for 30 minutes, it was immediately injected into the reaction solution in the four-neck bottle, and the entire injection process was about 20 seconds. After the injection was completed, the temperature was raised to 285°C and kept for 40 minutes. The reaction liquid is naturally cooled to room temperature, acetone is added to precipitate the product, the reaction mother liquid is taken out by ce...

Embodiment 3

[0038] Add 0.2mmol copper acetylacetonate, 0.3g dodecanediol, 0.8mmol trioctylphosphine oxide, 2ml oleylamine, and 3ml bibenyl ether into a four-neck flask, stir and mix under the protection of argon, and then heat up to 200 ℃, keep warm for 25min. In addition, add 0.15g of zinc acetate, 1ml of oleylamine, and 1.5ml of bibian ether into a three-necked bottle, stir under the protection of argon until the mixture is uniform, and keep the temperature at 75°C for about 15min, then suck up the mixed solution with a syringe, and wait for After the reaction solution in the four-necked bottle was kept warm for 25 minutes, it was immediately injected into the reaction solution in the four-necked bottle, and the whole injection process was about 40 s. After the injection was completed, the temperature was raised to 265°C and kept for 30 minutes. The reaction solution was naturally cooled to room temperature, ethanol was added to precipitate the product, and the reaction mother liquid w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com