Preparation method of high-temperature-resistant great-temperature-difference cement paste for oilfield well cementing

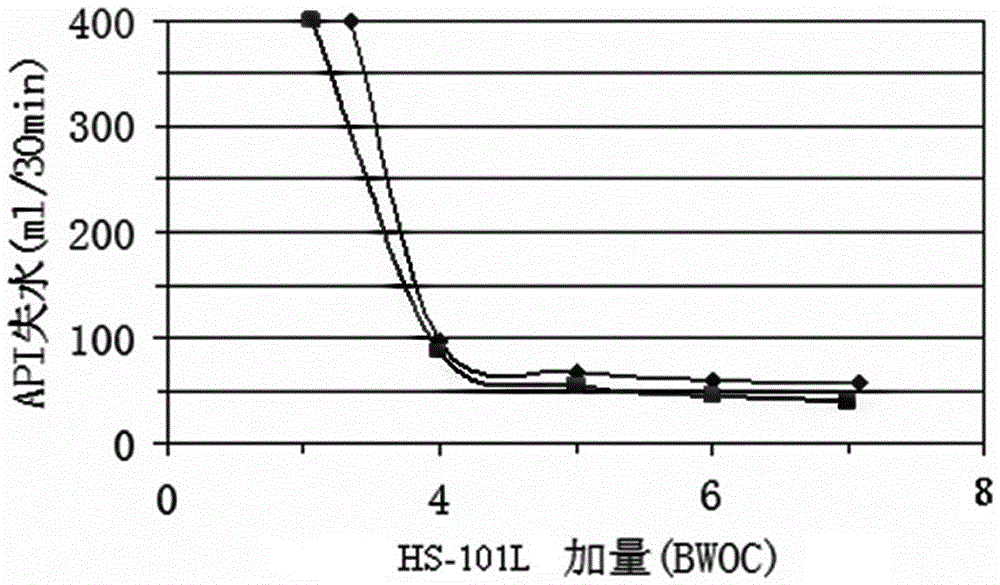

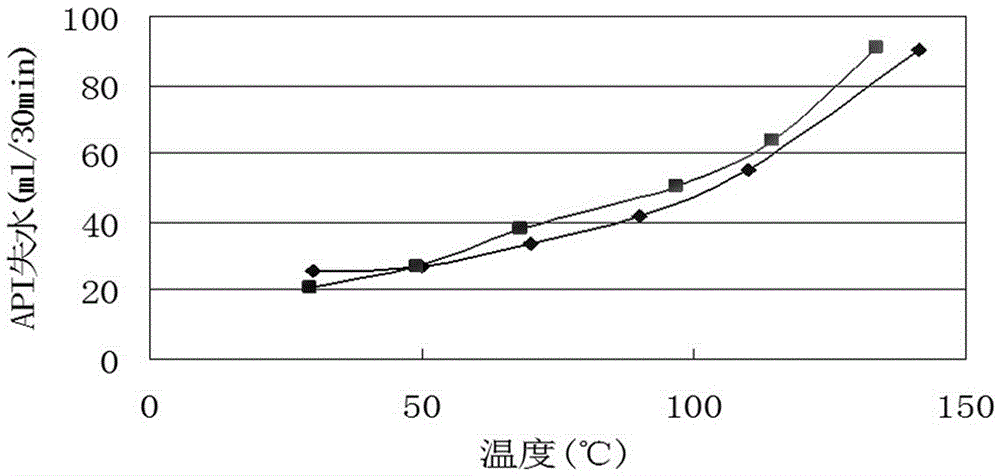

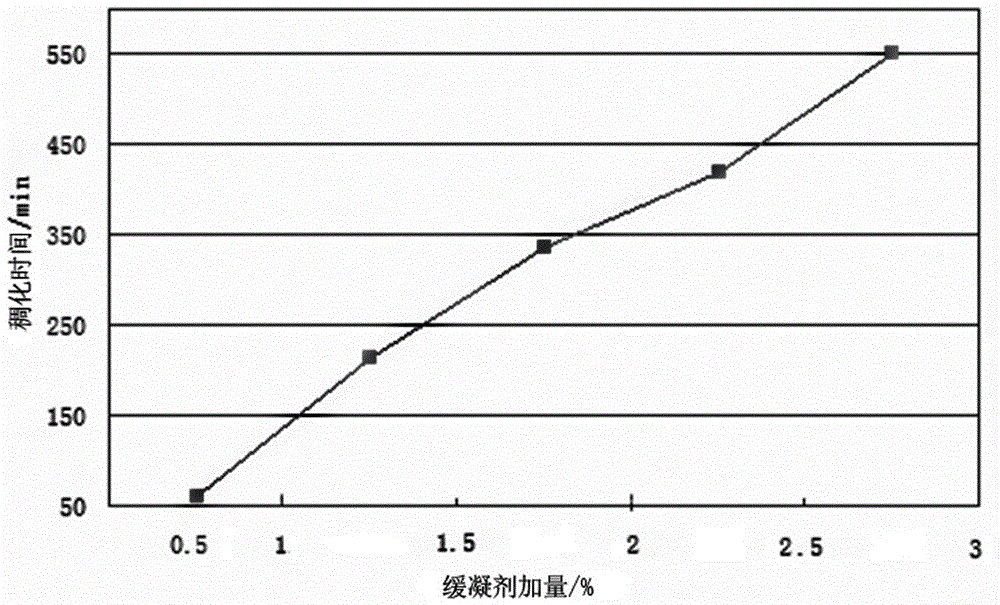

A technology for cement slurry and oil well cement, applied in the field of oil drilling, can solve the problems of long cement slurry thickening transition time, performance deterioration, sensitivity to temperature and amount of retarder, etc., to achieve excellent water loss reduction performance, prevent structure Formation and overcoming of dose sensitive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of the high-temperature-resistant and large-temperature-difference cement slurry for oilfield well cementing of the present invention comprises the following steps in turn: (1) prepare raw materials according to the following components and weight contents, G grade oil well cement: 600 parts, HS101L fluid loss reducer: 30 parts, HS201L retarder: 8 parts, HS-301S dispersant: 1.8 parts, quartz sand: 150 parts, microsilica fume: 30 parts, HS-XF1S suspension stabilizer: 1.8 parts, water: 280 parts and di(2-B Base hexyl) sodium succinate sulfonate: 1 part; the particle diameter of the quartz sand is 80-120 mesh, the particle diameter of the micro-silica fume is 300-400 mesh and the silicon dioxide content is more than 90%; (2) Add the above-mentioned water, HS101L fluid loss reducer and HS201L retarder into the mixing container and mix well; (3) Add the above-mentioned G-grade oil well cement, HS-301S dispersant, quartz sand, and microsilica into the so...

Embodiment 2

[0032]The preparation method of the high-temperature-resistant and large-temperature-difference cement slurry for oilfield well cementing of the present invention comprises the following steps in turn: (1) Prepare raw materials according to the following components and weight contents, G-grade oil well cement: 600 parts, HS101L fluid loss reducer: 33 parts, HS201L retarder: 14 parts, HS-301S dispersant: 1.8 parts, quartz sand: 150 parts, microsilica fume: 30 parts, HS-XF1S suspension stabilizer: 1.8 parts, water: 290 parts and di(2-B Base hexyl) sodium succinate sulfonate: 1 part; the particle diameter of the quartz sand is 80-120 mesh, the particle diameter of the micro-silica fume is 300-400 mesh and the silicon dioxide content is more than 90%; (2) Add the above-mentioned water, HS101L fluid loss reducer and HS201L retarder into the mixing container and mix well; (3) Add the above-mentioned G-grade oil well cement, HS-301S dispersant, quartz sand, and microsilica into the so...

Embodiment 3

[0039] The preparation method of the high-temperature-resistant and large-temperature-difference cement slurry for oilfield well cementing of the present invention comprises the following steps in turn: (1) prepare raw materials according to the following components and weight contents, G grade oil well cement: 600 parts, HS101L fluid loss reducer: 36 parts, HS201L retarder: 20 parts, HS-301S dispersant: 1.8 parts, quartz sand: 150 parts, microsilica fume: 30 parts, HS-XF1S suspension stabilizer: 1.8 parts, water: 300 parts and di(2-B Base hexyl) sodium succinate sulfonate: 1 part; the particle diameter of the quartz sand is 80-120 mesh, the particle diameter of the micro-silica fume is 300-400 mesh and the silicon dioxide content is more than 90%; (2) Add the above-mentioned water, HS101L fluid loss reducer and HS201L retarder into the mixing container and mix well; (3) Add the above-mentioned G-grade oil well cement, HS-301S dispersant, quartz sand, and microsilica into the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com