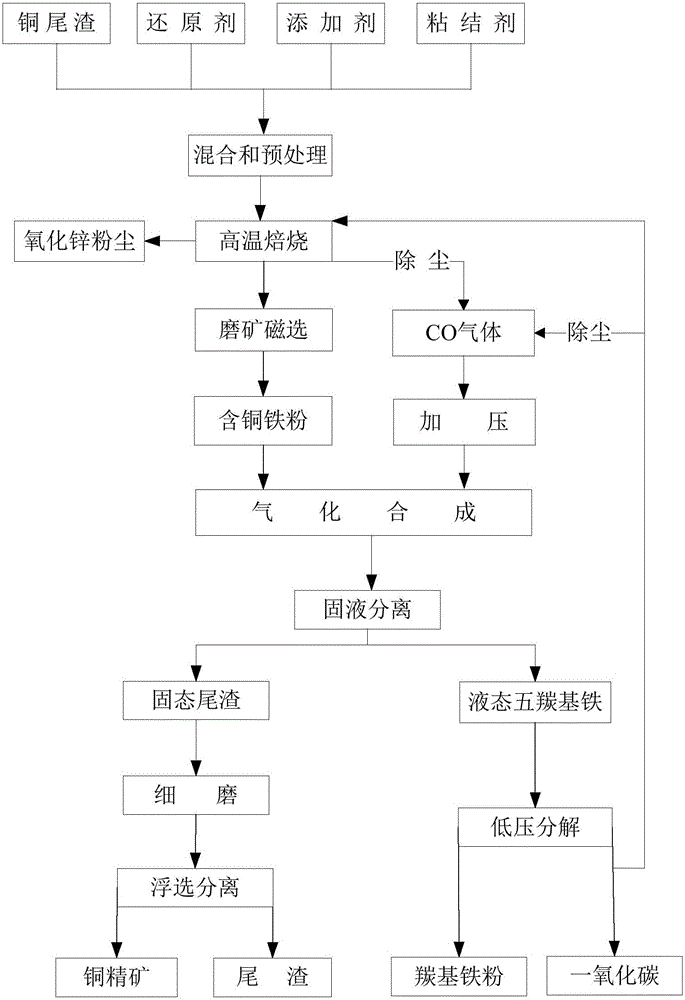

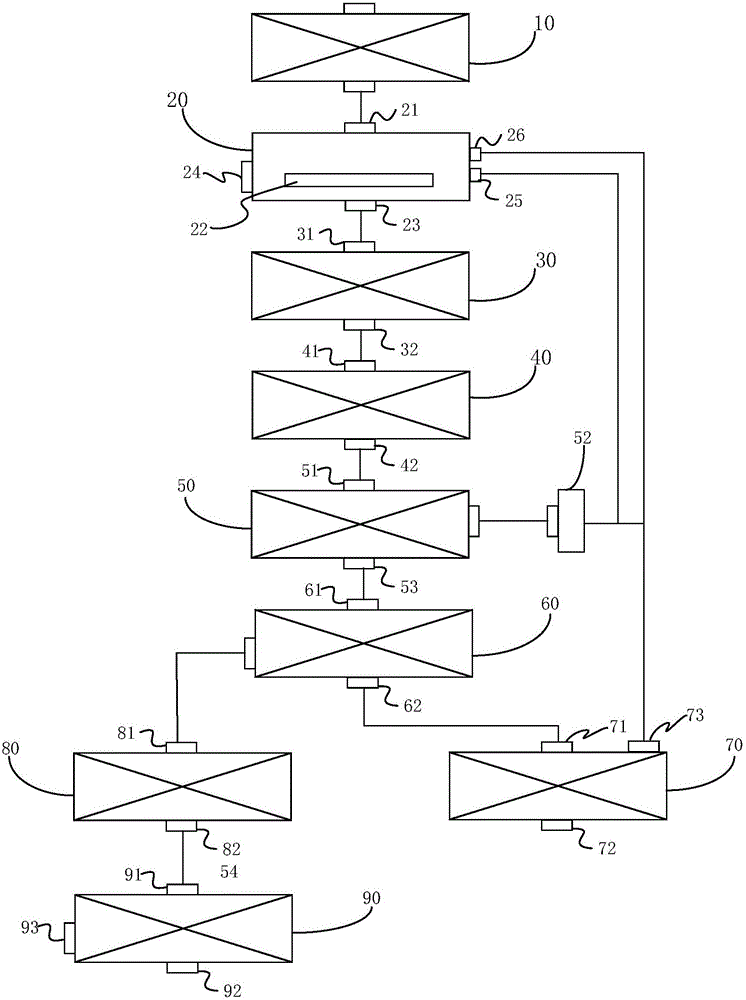

Method and system for utilizing copper tailings comprehensively

A technology of copper tailings and tailings, applied in the field of metallurgy, can solve the problems of difficult gas pollution, harsh conditions, and many process links, and achieve significant economic benefits and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0097] Copper tailings: reducing agent: additive: binder = 100:15:20:1 by mass ratio to pelletize, wherein the TFe grade of copper tailings is 35%, the Cu content is 0.4%, and the Zn content is 1%. , the S content is 0.1%, and its particle size is -0.045mm, accounting for 90%. The pelletized products are dried and put into the rotary hearth furnace for direct reduction. 50min, in the direct reduction process of the rotary hearth furnace, zinc oxide dust with a zinc content of 52% can be obtained through dust collection in the flue, and the roasted product can be obtained after two stages of grinding, and the iron powder containing copper can be obtained, and its TFe grade is 88%. The Cu content is 1%, the S content is <0.1%, and its particle size is -0.074mm, accounting for 60%.

[0098] Export the reducing atmosphere in the high temperature zone of the rotary hearth furnace, and then obtain CO gas containing a small amount of sulfur oxides after dust removal; the CO gas and t...

Embodiment example 2

[0104] Copper tailings: reducing agent: additive: binder = 100:20:10:3 by mass ratio to pelletize, wherein the TFe grade of copper tailings is 40%, the Cu content is 0.3%, and the Zn content is 1.5% , The S content is 0.3%, and its particle size is -0.045mm, accounting for 90%. The pelletized products are dried and put into the rotary hearth furnace for direct reduction. 40min, in the direct reduction process of the rotary hearth furnace, zinc oxide dust with a zinc content of 58% can be obtained through dust collection in the flue, and the roasted product can be obtained after two stages of grinding, and the iron powder containing copper can be obtained, and its TFe grade is 90%. Cu content is 0.5%, S content <0.4%, and its particle size is -0.074mm, accounting for 80%.

[0105] Export the reducing atmosphere in the high temperature zone of the rotary hearth furnace, and then obtain CO gas containing a small amount of sulfur oxides after dust removal; the CO gas and the CO ga...

Embodiment example 3

[0111] The copper tailings: reducing agent: binder = 100:30:5 are pelletized according to the mass ratio, wherein the TFe grade of the copper tailings is 45%, the Cu content is 0.2%, the Zn content is 2%, and the S content is 0.2%, and its particle size is -0.045mm, which accounts for 90%. After the pelletized product is dried, it is put into the rotary hearth furnace for direct reduction. During the direct reduction process of the rotary hearth furnace, zinc oxide dust with a zinc content of 62% can be obtained through dust collection in the flue, and the roasted product can be obtained after two-stage grinding and selection to obtain copper-containing iron powder with a TFe grade of 94% and a Cu content of 0.4 %, S content <0.4%, and its particle size is -0.074mm, accounting for 90%.

[0112] Export the reducing atmosphere in the high temperature zone of the rotary hearth furnace, and then obtain CO gas containing a small amount of sulfur oxides after dust removal; the CO ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com