Method for preparing high-performance CoSb3-based thermoelectric materials by one step

A thermoelectric material and high-performance technology, which is applied in the field of preparing high-performance CoSb3-based thermoelectric materials, can solve problems such as hindering the batch process, long synthesis cycle, and complex synthesis process, and achieve shortened preparation cycle, short preparation time, and simplified synthesis process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

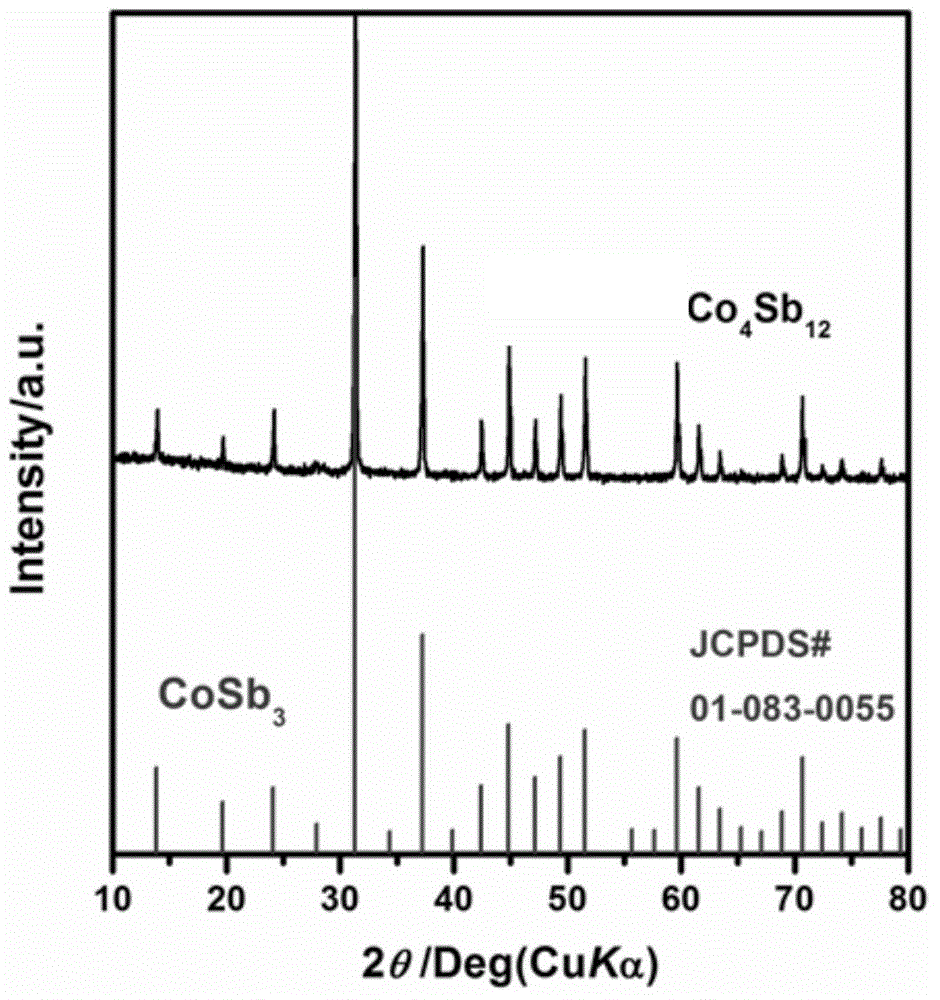

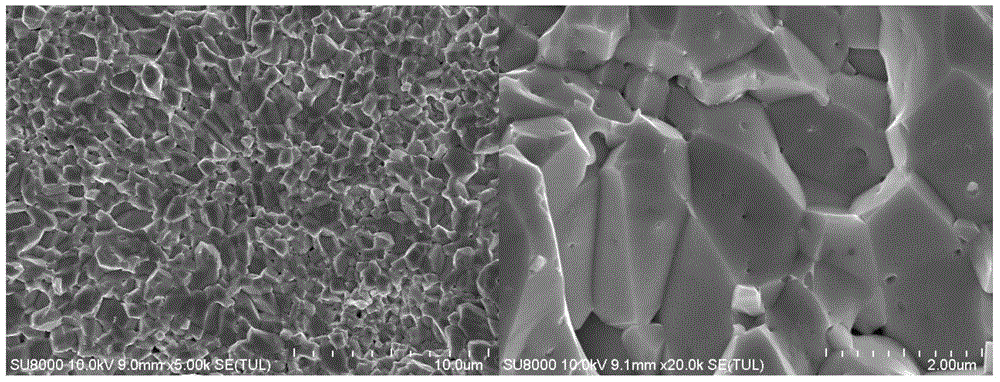

[0030] One-step rapid preparation of high-performance CoSb 3 method based on thermoelectric materials, according to the chemical formula Co 4 Sb 12 (ie chemical formula Co 4-x m x Sb 12-y Te y The stoichiometric ratio of elements Co and Sb in x=0 and y=0) is 4:12, that is, take Co powder and Sb powder as raw materials according to the molar ratio of 4:12, with a total mass of 4g; then the raw material powder Use an agate mortar to grind and mix evenly by hand, put it into a 16mm graphite mold and compact it for plasma activation sintering, and then sinter under a vacuum condition of less than 10Pa, the heating rate is 100°C / min, and the sintering temperature is 550°C , the sintering pressure is 40MPa, and the holding time is 5min, that is, high-performance CoSb can be obtained 3 The bulk thermoelectric material, that is, Co 4 Sb 12 Dense bulk thermoelectric materials.

[0031] It can be seen from Figure 1 that the obtained bulk thermoelectric material is a single-phas...

Embodiment 2

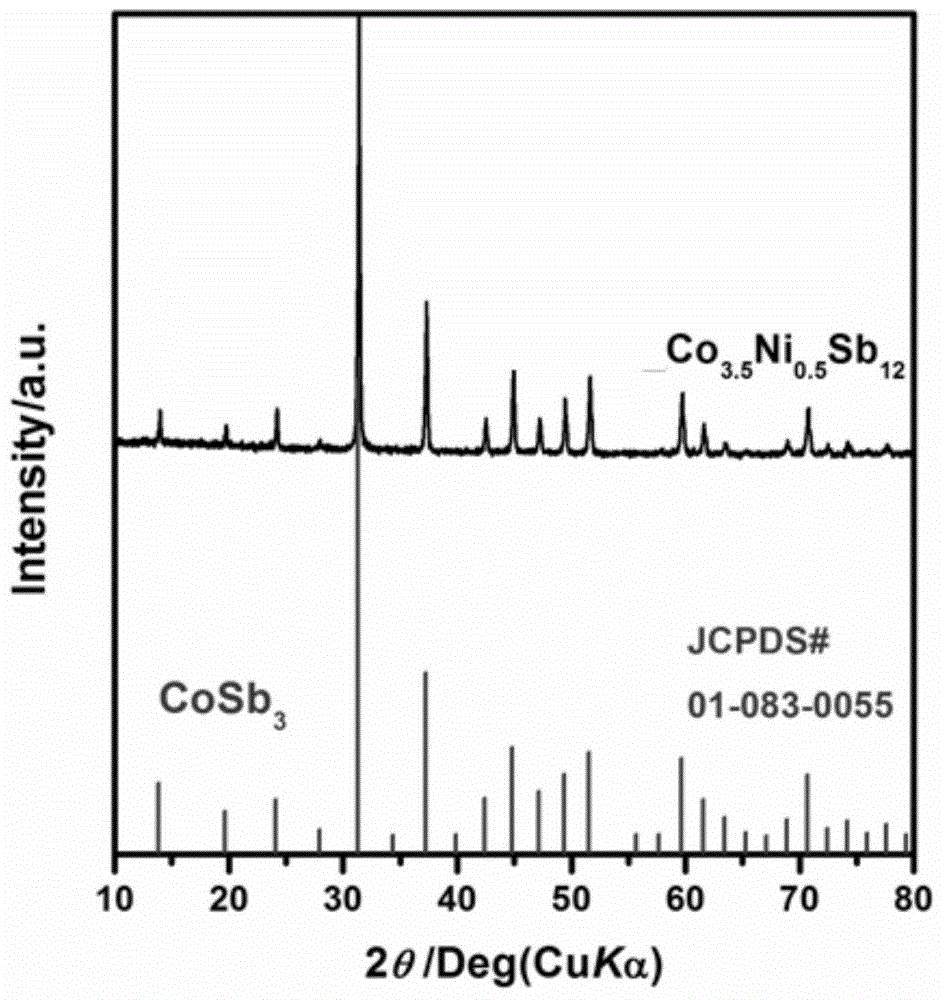

[0033] One-step rapid preparation of high-performance CoSb 3 method based on thermoelectric materials, according to the chemical formula Co 3.5 Ni 0.5 Sb 12 (ie chemical formula Co 4- x m x Sb 12-y Te y In x=0.5 and y=0), the stoichiometric ratio of elements Co, Ni, and Sb is 3.5:0.5:12, that is, Co powder, Ni powder, and Sb powder are taken as raw materials according to the molar ratio of 3.5:0.5:12, and the total The mass is 4g; then the raw material powder is manually ground and mixed evenly with an agate mortar, and then packed into a 16mm graphite mold for compaction for plasma activation sintering, and then sintered under a vacuum condition of less than 10Pa, with a heating rate of 100 ℃ / min, the sintering temperature is 550℃, the sintering pressure is 40MPa, and the holding time is 5min, that is, high-performance CoSb can be obtained 3 The bulk thermoelectric material, that is, Co 3.5 Ni 0.5 Sb 12 Dense bulk thermoelectric materials.

[0034] It can be seen ...

Embodiment 3

[0036] One-step rapid preparation of high-performance CoSb 3 method based on thermoelectric materials, according to the chemical formula Co 4 Sb 11.5 Te 0.5 (ie chemical formula Co 4- x m x Sb 12-y Te y In x=0 and y=0.5), the stoichiometric ratio of elements Co, Sb and Te is 4:11.5:0.5, that is, taking Co powder, Sb powder and Te powder as raw materials according to the molar ratio of 4:11.5:0.5, the total The mass is 4g; then, after the raw material powder is ground and mixed evenly, it is put into a 16mm graphite mold and compacted for plasma activation sintering, and then sintering is carried out under a vacuum condition of less than 10Pa, the heating rate is 100°C / min, and the sintering temperature at 550°C, sintering pressure at 40MPa, and holding time at 5min, high-performance CoSb can be obtained 3 The bulk thermoelectric material, that is, Co 4 Sb 11.5 Te 0.5 Dense bulk thermoelectric materials.

[0037] It can be seen from Figure 3 that the obtained bulk t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com