Preparation technology of matte imitating foamed wallpaper

A preparation process and frosting technology, applied in paper, papermaking, paper coating and other directions, can solve the problems of strong plastic texture and can not meet consumer demand, etc., and achieve the effect of fine surface, rich variety and comfortable hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

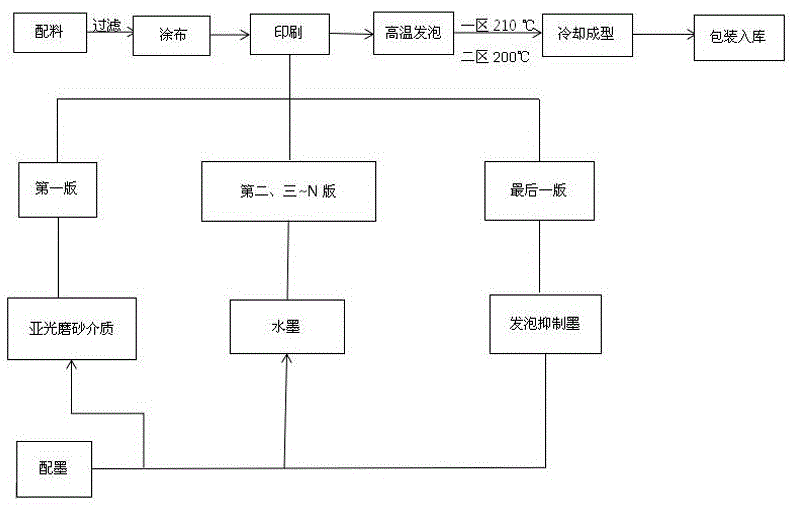

[0037] The new process for preparing frosted PVC foamed wallpaper is realized in the following ways:

[0038] 1. Production process of coating section:

[0039] A. Preparation of paste: first put in plasticizer, epoxy soybean oil, potassium zinc stabilizer, one-half of the amount of viscosity reducer, put it in a mixer and stir at low speed for 5 minutes, and then continuously add AC foaming agent and PVC paste Resin, titanium dioxide, calcium carbonate. After the addition is complete, stir evenly, and finally add one-half of the viscosity reducer to adjust the viscosity to 3000 CPS, and filter.

[0040] The components of the paste are as follows, in parts by weight,

[0041] Plasticizer 60

[0042] Epoxidized soybean oil 12

[0043] AC blowing agent 5

[0044] Potassium zinc stabilizer 5

[0046] PVC paste resin 100

[0047] Titanium dioxide 15

[0049] The plasticizer is DOP (dioctyl phthalate); the AC foaming agent is azodicarbo...

Embodiment 2

[0067] The new process for preparing the imitation frosted PVC foamed wallpaper, the paste ratio in the coating section is as follows, and the others are the same as in Example 1.

[0068] The components of the paste are as follows, in parts by weight,

[0069] Plasticizer 65

[0070] Epoxidized soybean oil 11

[0071] AC blowing agent 5.5

[0072] Potassium zinc stabilizer 5

[0074] PVC paste resin 120

[0075] Titanium Dioxide 10

[0077] The plasticizer is DOP (dioctyl phthalate); the AC foaming agent is azodicarbonamide; and the viscosity reducing agent is a low-sulfur and low-aromatic hydrocarbon solvent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com