A kind of polyferric sulfate and preparation method thereof

A technology for polymerizing ferric sulfate and waste sulfuric acid, applied in ferric sulfate, chemical instruments and methods, water/sewage treatment, etc., can solve problems such as long reaction cycle, equipment corrosion, heavy maintenance tasks, etc. Performance-boosting, high-acidity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

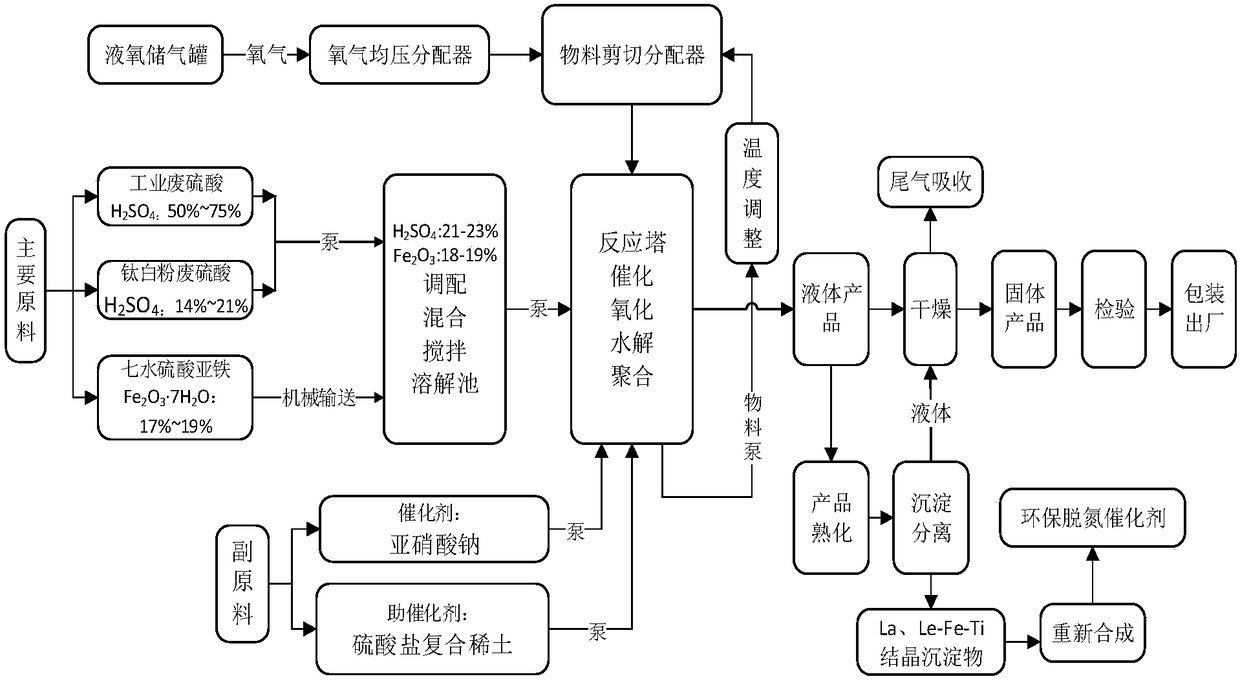

[0043] Refer below figure 1 Describe in detail an embodiment of the preparation method of polyferric sulfate provided by the present invention; as shown in the figure, the preparation process of primary polyferric sulfate in this embodiment mainly includes the following steps:

[0044] In step 1, transport ferrous sulfate heptahydrate with a weight ratio of 40%-50% and titanium dioxide waste sulfuric acid with a weight ratio of 60%-50% to the mixing tank for material mixing, and deploy titanium H in white powder waste sulfuric acid 2 SO 4 The concentration range is 21%-23%, and the mixed reaction materials are obtained; during specific implementation, industrial sulfuric acid can be used to adjust the H in the titanium dioxide waste sulfuric acid. 2 SO 4 concentration.

[0045] In step 2, the reaction materials are sent into the reaction tower, and during the process of the reaction materials entering the reaction tower, the weight proportion is 0.2%-0.4%, the metal concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com