Anion-exchange membrane for fuel cells and preparation method thereof, and fuel cell using anion-exchange membrane

An anion exchange membrane, fuel cell technology, applied in fuel cells, circuits, electrical components, etc., to achieve the effects of high electrical conductivity, chemical stability and mechanical properties improvement, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

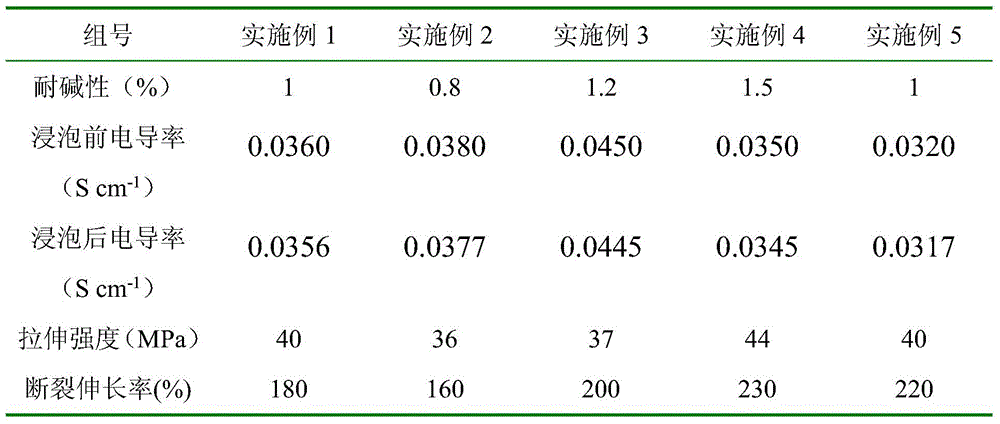

Examples

Embodiment 1

[0026] A method for preparing an anion exchange membrane for a fuel cell, comprising the steps of:

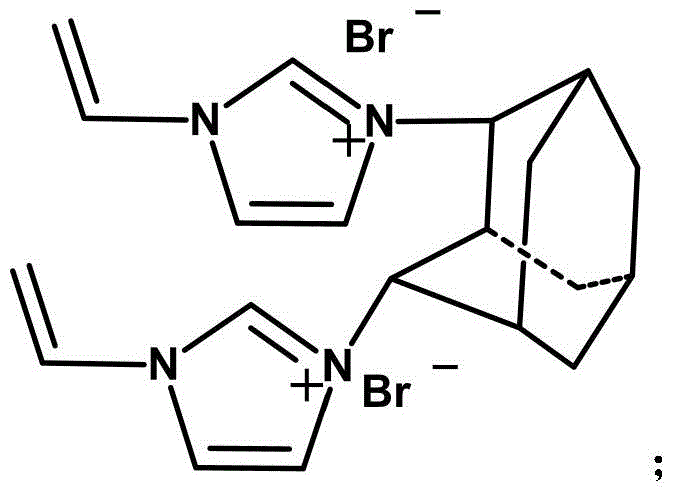

[0027] 1) Dissolve vinylimidazole (18.82g, 0.2mol) and 1,3-dibromoadamantane (29.4g, 0.1mol) in acetonitrile (113g), then add 25gKOH therein, and under nitrogen atmosphere at room temperature Stir for 4 hours. Then rotary evaporate under vacuum to remove the solvent, the obtained crude product was extracted 5 times with dichloromethane, then the organic phase was washed with deionized water, finally dehydrated with anhydrous magnesium sulfate, filtered, rotary evaporated, and heated in vacuum at 40°C Bake down for 12 hours to obtain a polymeric ionic liquid;

[0028] 2) Mix 30 g of the polymeric ionic liquid obtained in step 1), 10 g of methyl methacrylate and 1 g of emulsifier polyoxypropylene polyvinyl glyceryl ether, drop it on a glass plate 20 microns apart, and place it under a nitrogen atmosphere In the radiation field, the cobalt 60-γ radiation method was used to irrad...

Embodiment 2

[0031] A method for preparing an anion exchange membrane for a fuel cell, comprising the steps of:

[0032] 1) Dissolve vinylimidazole (18.82g, 0.2mol) and 1,3-dibromoadamantane (29.4g, 0.1mol) in acetonitrile (113g), then add 30gKOH therein, and under nitrogen atmosphere at room temperature Stir for 4 hours. Then rotary evaporation under vacuum to remove the solvent, the obtained crude product was extracted 3-5 times with dichloromethane, then the organic phase was washed with deionized water, finally dehydrated with anhydrous magnesium sulfate, filtered, rotary evaporation, and in vacuo Bake at 40°C for 12 hours to obtain a polymeric ionic liquid;

[0033] 2) 30g of the polymeric ionic liquid obtained in step 1), 10g of acrylonitrile and 1g of emulsifier sodium dodecylbenzenesulfonate are mixed, dropped on a glass plate 30 microns apart, and placed in a radiation chamber under a nitrogen atmosphere. In the field, the cobalt 60-γ radiation method was used to irradiate, and ...

Embodiment 3

[0036] A method for preparing an anion exchange membrane for a fuel cell, comprising the steps of:

[0037] 1) Dissolve vinylimidazole (18.82g, 0.2mol) and 1,3-dibromoadamantane (29.4g, 0.1mol) in acetonitrile (112.92g), then add 22.4gKOH, and nitrogen at room temperature Stir under atmosphere for 4 hours. Then rotary evaporate under vacuum to remove the solvent, the obtained crude product was extracted 3 times with dichloromethane, then the organic phase was washed with deionized water, finally dehydrated with anhydrous magnesium sulfate, filtered, rotary evaporated, and heated in vacuum at 30°C Bake down for 12 hours to obtain a polymeric ionic liquid;

[0038] 2) Mix 30 g of the polymeric ionic liquid obtained in step 1), 10 g of sulfonated styrene and 1 g of emulsifier nonylphenol polyoxyethylene ether, drop it on a glass plate 22 microns apart, and put it into a In the radiation field, the cobalt 60-γ radiation method was used to irradiate for 30 minutes, and the polyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com