Hydrocarbon resistance fire-proof and explosion-proof coating

A technology for coatings and hydrocarbon resistance, applied in the direction of fireproof coatings, coatings, etc., can solve the problems of two-component on-site mixing, poor metal surface wettability, high solid content of two components, etc., and achieve high hydrocarbon fire resistance limit, Low construction cost and good salt corrosion resistance

Active Publication Date: 2016-06-22

应急管理部四川消防研究所

View PDF5 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the two-component coating has high solid content, high viscosity, difficult two-component on-site blending, poor coating leveling, and poor wettability with metal surfaces, resulting in poor coating properties, difficult construction, difficult quality control, and low fire resistance. high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

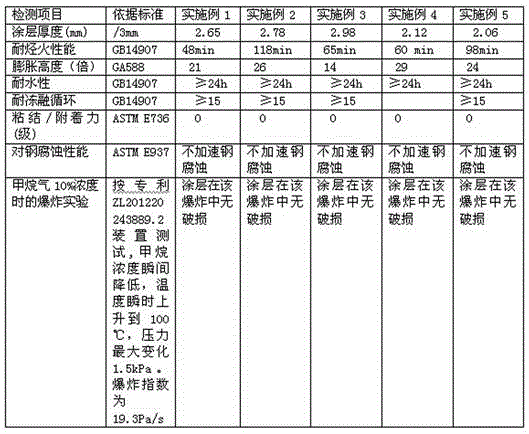

[0016] Table 1: Component proportions of Examples 1 to 5 (by weight):

[0017]

[0018] The above-mentioned components are mixed evenly, ground, and sieved at 80 μm to obtain the hydrocarbon-resistant fireproof and explosion-proof coating of the present invention. Wherein, the preparation method of latex powder, polypolyol phosphate flame retardant and modified expanded vermiculite is as above.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a hydrocarbon resistance fire-proof and explosion-proof coating which is prepared from, by weight, 20-60 parts of emulsion powder, 0-20 parts of polyvinyl alcohol, 1-3 parts of hydrogenated castor oil, 15-35 parts of polyvalent alcohol phosphate flame retardant, 5-13 parts of melamine cyanurate, 4-16 parts of zinc borate, 3-6 parts of modified expanded vermiculite and 0-2 parts of rutile type nanometer titania. The coating is high in hydrocarbon fire resistance limit, also has the explosion resistance, can adhere to a base material in the good condition after an explosion happens, enables a coating film to have the pressure relief function in the explosion, and is good in adhesion force, high in strength, capable of withstanding influences of high and low temperature cycling, good in water resistance, acid-base resistance, salt corrosion resistance and weather resistance, good in flexibility, not prone to disengagement, stable in storage, long in service life, environmentally friendly, convenient to construct, low in construction cost, simple in preparation technology and low in energy consumption. The hydrocarbon resistance fire-proof and explosion-proof coating is particularly suitable for being used as surface coatings of steel materials, aluminum materials and other materials in indoor and outdoor petrochemical industries.

Description

Technical field: [0001] The invention relates to a fireproof and explosion-proof coating, in particular to a hydrocarbon-resistant fireproof and explosion-proof coating. Background technique: [0002] Most of the fires in petrochemical enterprises are typical hydrocarbon fires. Hydrocarbon fires generally heat up faster and have more violent flames than cellulose fires. In hydrocarbon fires, the effectiveness of conventional fire protection coatings designed for cellulosic fires is only about 60% in hydrocarbon fires, and when hydrocarbon fires occur, explosions are often accompanied. Chinese patent 200610091048.3 discloses a solvent-free intumescent fireproof coating, which is composed of two components A and B. The component A uses epoxy resin as the main film-forming substance, and adds modified resin, catalyst, char-forming agent, and foaming agent. , flame retardant, flux, pigment and filler, smoke suppressant, component B is composed of pigment and filler, curing agen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D151/00C09D7/12C09D5/18

CPCC08L2201/02C08L2205/03C09D5/185C09D151/00C08L29/04C08L91/00C08K13/06C08K9/06C08K3/34C08K2003/222C08K5/521C08K5/34924C08K2003/387C08K2003/2241

Inventor 张泽江梅秀娟

Owner 应急管理部四川消防研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com