Nano composite NdFeB (neodymium iron boron) permanent magnetic material and preparation method

A nano-composite, NdFeB technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of easy powder corrosion, poor temperature characteristics, low coercivity of NdFeB magnets, etc. Good performance, improved machinability, and obvious effect of nano-enhancing and toughening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

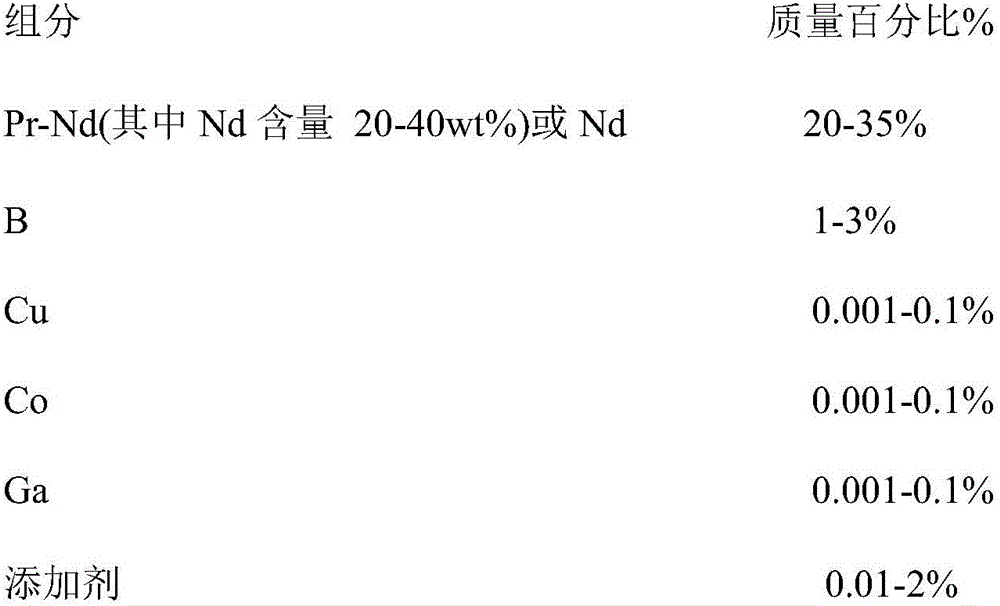

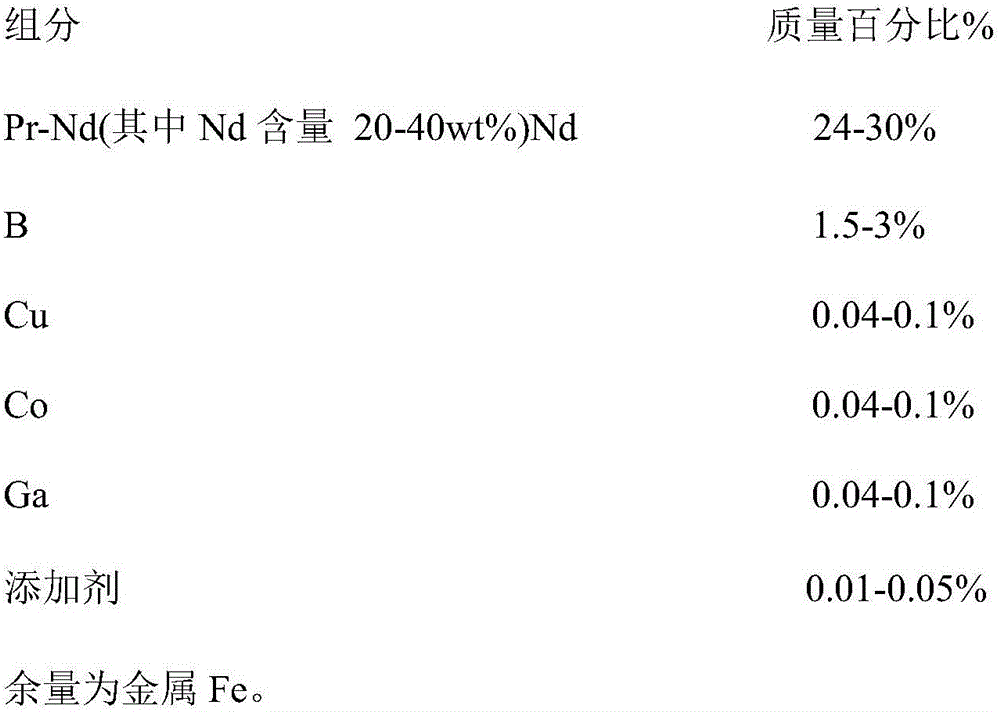

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of nanocomposite NdFeB permanent magnet material, the steps are as follows:

[0027] (1) earlier powder raw material Pr-Nd alloy (wherein Nd content 20wt%) 300kg, B15kg, metal Fe669.5kg, Cu0.5kg, Co0.5kg, Ga0.5kg (each component metal powder particle diameter is in 100-500nm between) under the hydrogen pressure of 0.6Mpa, absorb hydrogen for 2 hours, and then dehydrogenate for 4 hours at a temperature of 650 ° C; after dehydrogenation, cool to 25 ° C, and the powder raw materials are sintered at high temperature and then agglomerated into a particle size of 90-140 mesh coarse granule spare;

[0028] (2) Grind the above-mentioned coarse particles to a fine powder with an average particle size of 3.0 μm under a working pressure of 0.12-0.18Mpa with a jet mill; then, add 0.5kg particle size Mesoporous silica of 100-200nm and pore size of 6-20nm, and stirred and mixed in a mixer for 3 hours, so as to realize the uniform adsorption of nano-additives in ...

Embodiment 2

[0031] A preparation method of nanocomposite NdFeB permanent magnet material, the steps are as follows:

[0032] (1) First put the powder raw material Pr-Nd alloy (wherein the Nd content is 30wt%) 280kg, B20kg, metal Fe696.8kg, Cu1kg, Co1kg, Ga1kg (the particle size of each component metal powder is between 100-500nm) at 1.0Mpa Under the pressure of hydrogen, absorb hydrogen for 3 hours, and then dehydrogenate for 7 hours at a temperature of 700 ° C; after dehydrogenation, cool to 25 ° C, and the powder raw materials are sintered at high temperature and then agglomerated into coarse particles with a particle size of 90-140 mesh for later use;

[0033] (2) Grind the above-mentioned coarse particles into a fine powder with an average particle size of 4.0um under a working pressure of 0.12-0.18Mpa with a jet mill; then, in a helium protective atmosphere, add 0.2kg of particles Mesoporous silicon carbide with a diameter of 50-100m and a pore diameter of 10-20nm is stirred and mixe...

Embodiment 3

[0036] A preparation method of nanocomposite NdFeB permanent magnet material, the steps are as follows:

[0037] (1) earlier powder raw material Pr-Nd alloy (wherein Nd content 40wt%) 220kg, B30kg, metal Fe747.1kg, Cu0.4kg, Co0.4kg, Ga1kg (each component metal powder particle size is between 100-500nm ) under a hydrogen pressure of 0.8Mpa, absorb hydrogen for 5 hours, and then dehydrogenate for 3 hours at a temperature of 430°C; after dehydrogenation, cool to 25°C, and the powder raw materials are sintered at high temperature and then agglomerated into coarse particles with a particle size of 90-140 mesh for later use (2) the above-mentioned coarse particles are ground to a fine powder with an average particle diameter of 3.0um under a working pressure of 0.12-0.18Mpa with a jet mill; then, in a helium protective atmosphere, compoundly add 1.1kg Mesoporous boron carbide with a particle size of 30-90nm and a pore size of 3-9nm is stirred and mixed in a mixer for 4 hours, so tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com