Light emitting diode epitaxy structure provided with P-type ohmic contact layer

A technology of ohmic contact layer and light-emitting diode, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., to improve the characteristics of P-type ohmic contact, save production costs, and overcome the difficulty of forming P-type ohmic contact and hole supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

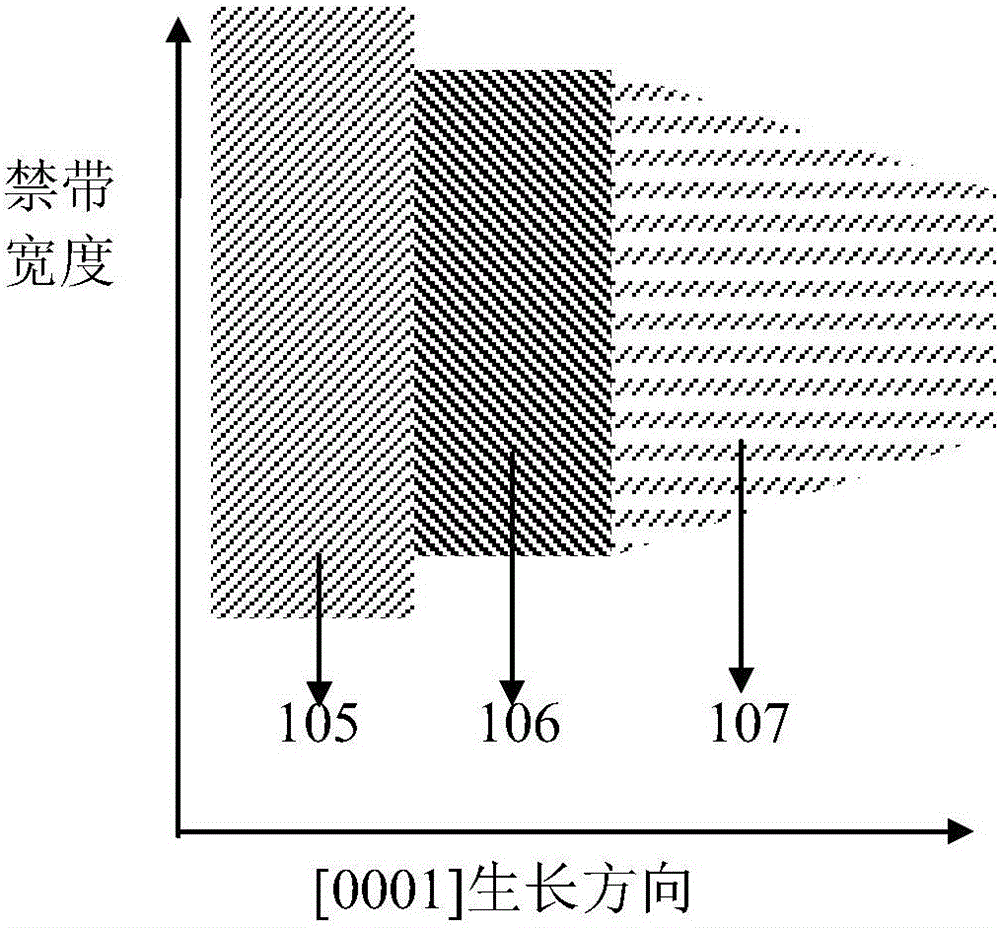

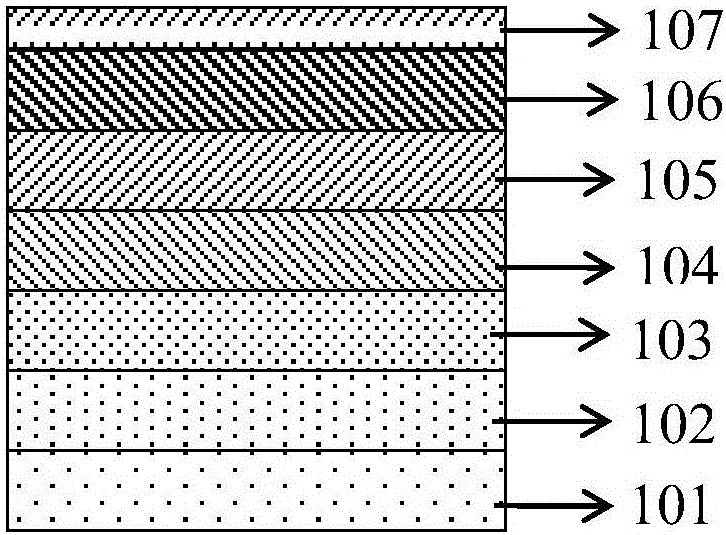

[0033] The light-emitting diode epitaxial structure with a P-type ohmic contact layer in this embodiment includes a sapphire substrate 101, a buffer layer 102 made of AlN material with a thickness of 25 nm, and an N-type AlN material with a thickness of 4 μm from bottom to top. Semiconductor material layer 103, quantum well Al with a quantum barrier AlN thickness of 10 nm 0.8 Ga 0.2 Al with N thickness of 5 nm 0.8 Ga 0.2 Multiple quantum well layer 104 made of N / AlN material, P-type electron blocking layer 105 made of AlN material with a thickness of 50 nm, and Al with a thickness of 150 nm 0.9 Ga 0.1 P-type semiconductor material transport layer 106 of N material and Al with a thickness of 10 nm x Ga 1-x For the P-type ohmic contact layer 107 made of N material, where x is linearly graded from 0.9 to 0, its lattice constant gradually increases along the growth direction, and the forbidden band width gradually decreases.

[0034] The light-emitting diode epitaxial struct...

Embodiment 2

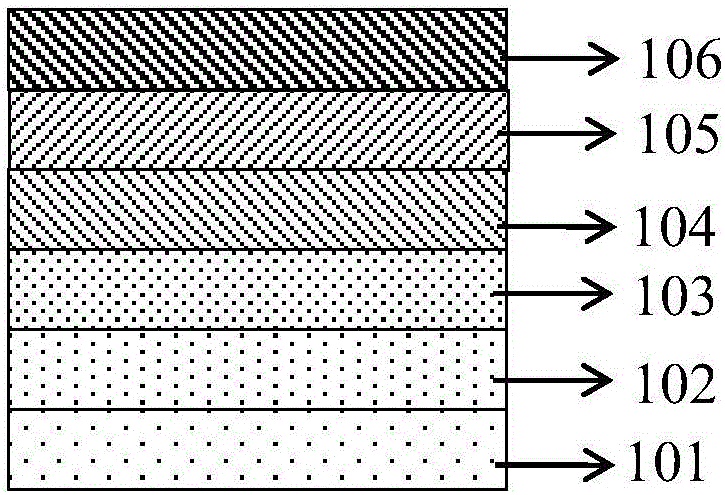

[0042] The light-emitting diode epitaxial structure with a P-type ohmic contact layer of this embodiment includes a Si substrate 101 and Al with a thickness of 10 nm from bottom to top. 0.2 In 0.3 Ga 0.5 Buffer layer 102 of N material, Al with a thickness of 2 μm 0.1 In 0.5 Ga 0.4 N-type semiconductor material layer 103 made of N material, quantum well In with a quantum barrier GaN thickness of 10 nm 0.8 Ga 0.2 In with N thickness of 5 nm 0.8 Ga 0.2 A multiple quantum well layer 104 made of N / GaN material, a P-type electron blocking layer 105 made of AlN material with a thickness of 10 nm, a P-type semiconductor material transport layer 106 made of AlN material with a thickness of 100 nm, and Al with a thickness of 150 nm x In y Ga 1-x-y P-type ohmic contact layer 107 made of N material, in the formula, the first 100nm growth keeps y=0, and x gradually changes from 0.9 to 0; the last 50nm growth keeps x=0, y changes nonlinearly from 0 to 0.1, and the whole P The -typ...

Embodiment 3

[0051] The light-emitting diode epitaxial structure with a P-type ohmic contact layer in this embodiment includes a SiC substrate 101, a GaN buffer layer 102 with a thickness of 50 nm, and an N-type GaN material with a thickness of 8 μm from bottom to top. A semiconductor material layer 103, a quantum well In with a quantum barrier GaN thickness of 10 nm 0.8 Ga 0.2 In with N thickness of 5 nm 0.8 Ga 0.2 Multiple quantum well layer 104 made of N / GaN material, Al with a thickness of 100 nm 0.2 Ga 0.8 P-type electron blocking layer 105 of N material, P-type semiconductor material transport layer 106 of GaN material with a thickness of 500 nm, and In x Ga 1-x P-type ohmic contact layer 107 made of N material, in the formula, the first 100nm growth x linearly changes from 0 to 0.2, and the last 100nm growth x linearly changes from 0.2 to 1, so that its lattice constant gradually increases along the growth direction, and the forbidden The tape width gradually decreases.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com