Wetting agent for pesticide preparations, method for preparing wetting agent and application of wetting agent to pesticide preparations

A technology for pesticide preparation and wetting agent, which is applied in the field of pesticide preparation wetting agent and its preparation, and achieves the effects of reducing environmental pollution, having strong micelle-forming ability and promoting photosynthesis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

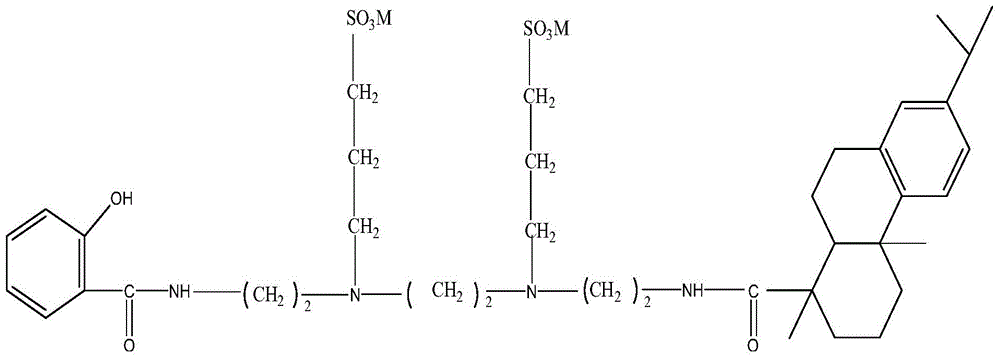

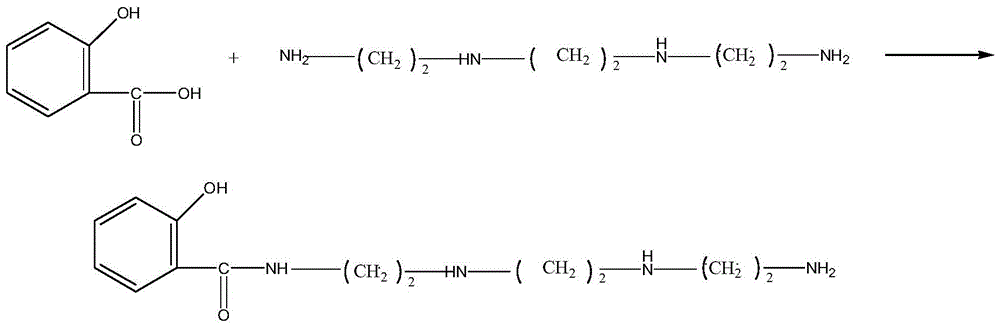

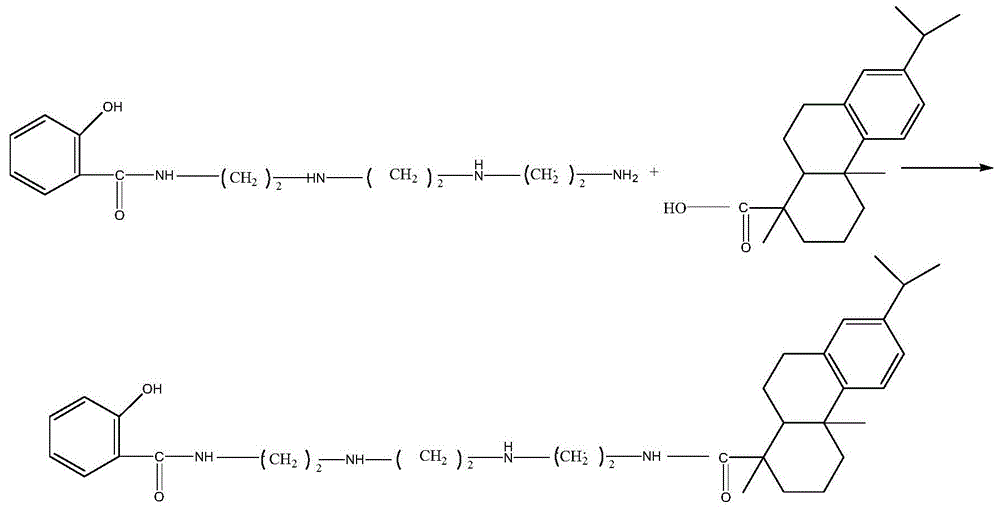

[0032] Add 20.7 grams of salicylic acid and catalyst potassium hydroxide (adding by salicylic acid quality 1.5%) in the 250ml four-neck flask that condenser tube, thermometer and stirrer are housed, open stirring, be warming up to 90 ℃ under nitrogen protection, Slowly add 24.1 grams of triethylenetetramine dropwise to the reactor, and the dropwise addition is completed within 1 hour, then react at a constant temperature of 150-160°C for 6 hours, and cool to 25-30°C to obtain an intermediate monoamide, which is in the reactor Then add 45 grams of dehydroabietic acid, start stirring, raise the temperature to 90°C under the protection of nitrogen, then react at a constant temperature of 150-160°C for 6 hours, cool to 25-30°C, use 150# solvent oil and butanone mixed solvent (Volume ratio 1:1) recrystallize 3 times, remove by-products, dry in a vacuum oven at 60°C to constant weight, and obtain a white powder that is an intermediate asymmetric bisamide with a purity of more than 95...

Embodiment 2

[0035]Add 20.7 grams of salicylic acid and catalyst potassium hydroxide (adding by salicylic acid quality 1.5%) in the 250ml four-neck flask that condenser tube, thermometer and stirrer are housed, open stirring, be warming up to 90 ℃ under nitrogen protection, Slowly add 24.1 grams of triethylenetetramine dropwise to the reactor, and the dropwise addition is completed within 1 hour, then react at a constant temperature of 150-160°C for 6 hours, and cool to 25-30°C to obtain an intermediate monoamide, which is in the reactor Then add 45 grams of dehydroabietic acid, start stirring, raise the temperature to 90°C under the protection of nitrogen, then react at a constant temperature of 150-160°C for 6 hours, cool to 25-30°C, use 150# solvent oil and butanone mixed solvent (Volume ratio 1:1) recrystallize 3 times, remove by-products, dry in a vacuum oven at 60°C to constant weight, and obtain a white powder that is an intermediate asymmetric bisamide with a purity of more than 95%...

Embodiment 3

[0038] Add 20.7 grams of salicylic acid and catalyst potassium hydroxide (adding by salicylic acid quality 1.5%) in the 250ml four-neck flask that condenser tube, thermometer and stirrer are housed, open stirring, be warming up to 90 ℃ under nitrogen protection, Slowly add 24.1 grams of triethylenetetramine dropwise to the reactor, and the dropwise addition is completed within 1 hour, then react at a constant temperature of 150-160°C for 6 hours, and cool to 25-30°C to obtain an intermediate monoamide, which is in the reactor Then add 45 grams of dehydroabietic acid, start stirring, raise the temperature to 90°C under the protection of nitrogen, then react at a constant temperature of 150-160°C for 6 hours, cool to 25-30°C, use 150# solvent oil and butanone mixed solvent (Volume ratio 1:1) recrystallize 3 times, remove by-products, dry in a vacuum oven at 60°C to constant weight, and obtain a white powder that is an intermediate asymmetric bisamide with a purity of more than 95...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com