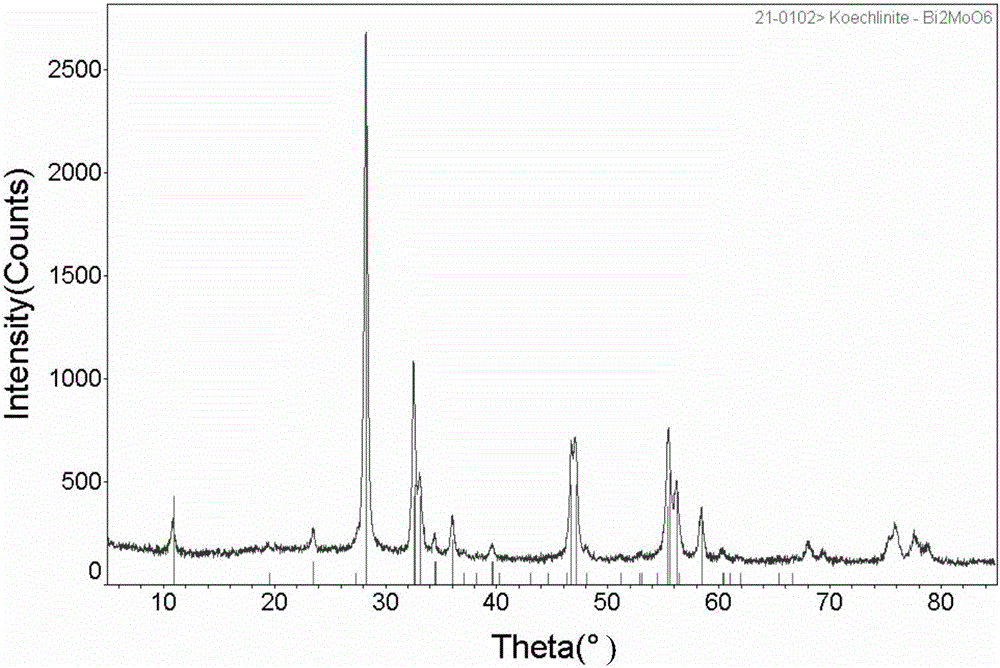

Preparation method of bismuth molybdate nano-wafer

A technology of nano-chips and bismuth molybdate, which is applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as separation difficulties, reduction of photocatalytic activity of photocatalytic materials, particle agglomeration, etc., and achieve simple preparation and high specific surface area. Large, low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

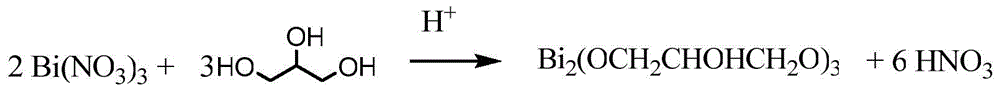

[0020] 1) Dissolve 10 mmol of bismuth nitrate and 30 mmol of glycerin in 4 mol (305 mL) of isopropanol, stir evenly to obtain a clear liquid, transfer the solution to an autoclave with a volume of 500 mL, heat up to 160°C and keep it warm for 6 hours. After stopping the heating, wait for the reactor to cool down to room temperature, filter and wash the filter cake with isopropanol for 3 times, and dry the filter cake at 80°C for 12 hours to obtain bismuth glycerol powder;

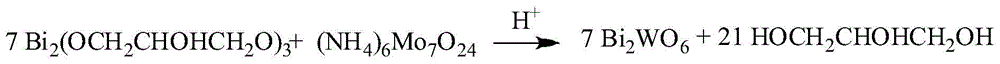

[0021] 2) Take 10mmol of ammonium heptamolybdate and dissolve it in 100ml of deionized water, then add 68mmol of bismuth glycerol to the above deionized aqueous solution, stir vigorously to disperse the bismuth glycerol evenly, adjust the pH value to between 1-2, and then mix the mixture Transfer to an autoclave with a volume of 200ml, raise the temperature to 180°C and keep it warm for 12 hours. After stopping the heating, wait for the reaction kettle to cool down to room temperature, filter and wash the f...

Embodiment 2

[0023] 1) Dissolve 10 mol of bismuth nitrate and 15 mol of glycerin in 1000 mol (76.4 L) of isopropanol, stir evenly to obtain a clear solution, transfer the solution to an autoclave with a volume of 100 L, heat up to 160°C and keep it warm for 12 hours. After stopping the heating, wait for the reactor to cool down to room temperature, filter and wash the filter cake with isopropanol for 3 times, and dry the filter cake at 80°C for 12 hours to obtain bismuth glycerol powder;

[0024] 2) Dissolve 10 mol of ammonium heptamolybdate in 20 liters of deionized water, then add 70 mol of bismuth glycerol to the above deionized aqueous solution, vigorously stir to disperse the bismuth glycerol evenly, adjust the pH value to between 0-1, and then mix the mixture Transfer to an autoclave with a volume of 25 liters, raise the temperature to 180° C. and keep it warm for 24 hours. After stopping the heating, wait for the reaction kettle to cool down to room temperature, filter and wash the ...

Embodiment 3

[0026] 1) Dissolve 100 mmol of bismuth nitrate and 20 mmol of glycerin in 32 mol (2.5 L) of isopropanol, stir evenly to obtain a clear solution, transfer the solution to an autoclave with a volume of 4 liters, heat up to 160° C. and keep it warm for 3 hours. After stopping the heating, wait for the reactor to cool down to room temperature, filter and wash the filter cake with isopropanol for 3 times, and dry the filter cake at 80°C for 12 hours to obtain bismuth glycerol powder;

[0027] 2) Dissolve 100mmol) of ammonium heptamolybdate in 100ml of deionized water, then add 720mmol of bismuth glycerol to the above deionized aqueous solution, stir vigorously to disperse the bismuth glycerol evenly, adjust the pH value to between 1-2, and then mix The liquid was transferred to an autoclave with a volume of 200 ml, and the temperature was raised to 180° C. and kept for 24 hours. After stopping the heating, wait for the reaction kettle to cool down to room temperature, filter and wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com