Fenton-like technique and reactor for treating biochemical effluent

A biochemical effluent and reactor technology, applied in water/sewage treatment, chemical instruments and methods, special compound water treatment, etc., can solve the problems of poor biodegradability of coking wastewater, inability to achieve stability, large fluctuations in water quality and water volume, etc., to achieve Meet the wastewater discharge requirements, save manpower, and maintain a stable treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

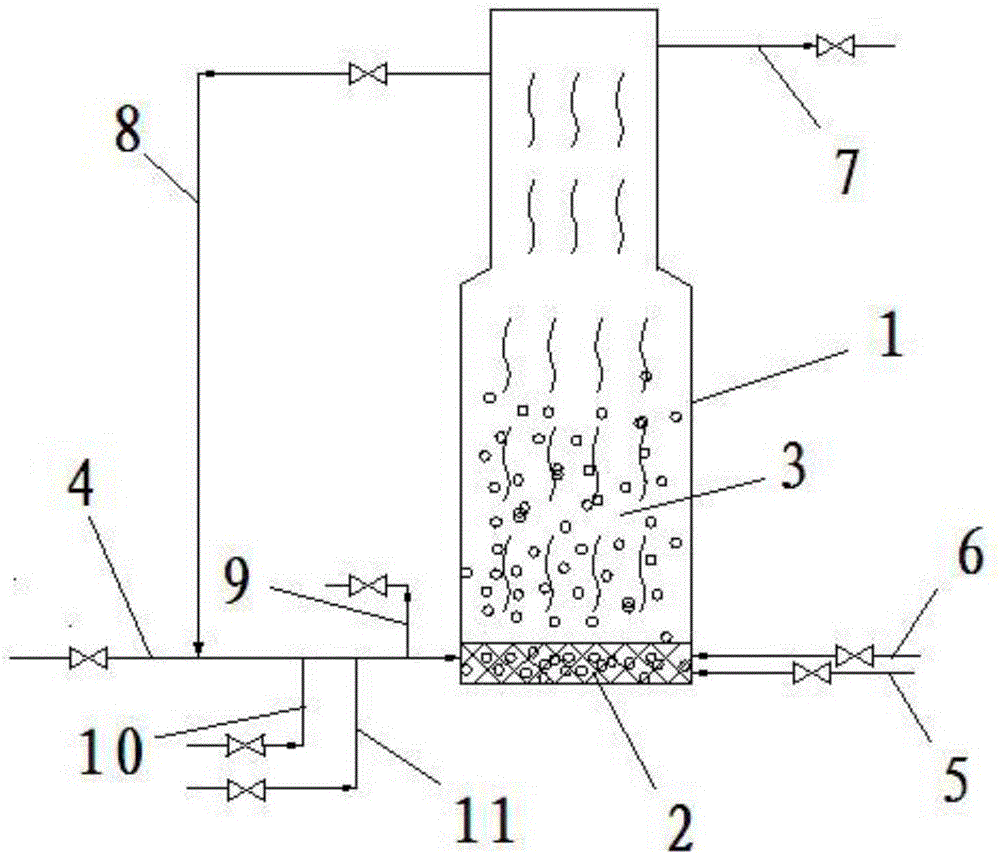

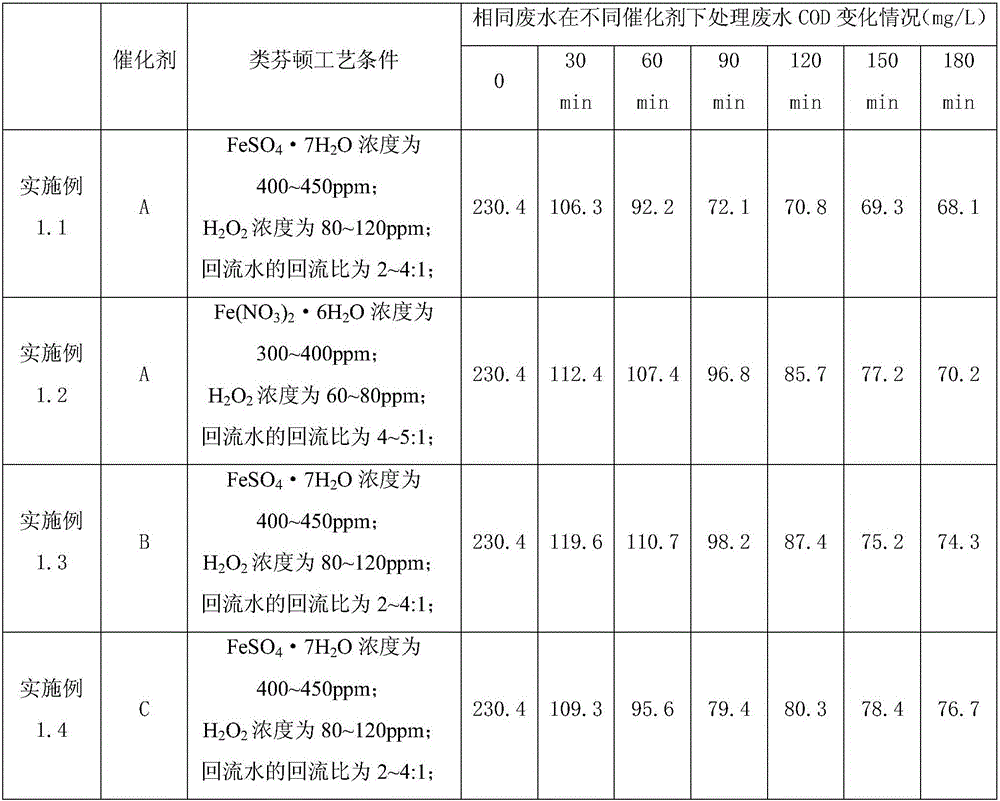

[0027] This embodiment relates to a Fenton-like process for advanced treatment of biochemical effluent.

[0028] exist figure 1 In the shown reactor, the biochemical effluent (the biochemical effluent of coking wastewater is used in this embodiment, and its COD is 230.4mg / L) is subjected to the advanced treatment of the Fenton-like oxidation reaction under the joint action of ferrous salt solution and hydrogen peroxide . In the process of advanced wastewater treatment, control the pH of the wastewater to be advanced treatment to 6.0-7.0, and dilute H can be selected. 2 SO 4 solution or dilute NaOH solution to adjust the pH of the wastewater, and then continuously input it to the bottom of the reactor; continuously inject the ferrous salt solution and hydrogen peroxide into the reactor from the other side of the bottom of the reactor; fix the Fenton-like reaction catalyst part in a fixed state in the reaction In the fixed bed with structured packing at the bottom of the reac...

Embodiment 2

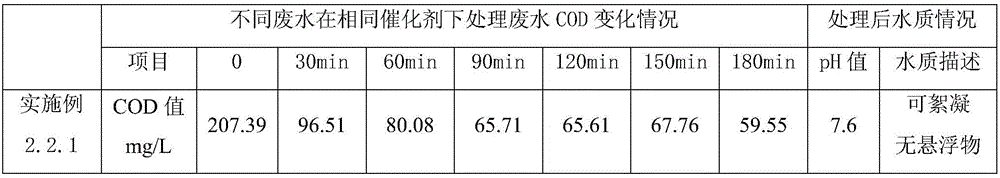

[0036] This embodiment relates to the comparison of the treatment effects of different biochemical effluents by using the Fenton-like process of the present invention.

[0037] Using the Fenton-like process of the present invention, under optimal process conditions, FeSO 4 ·7H 2 O solution, and FeSO 4 ·7H 2 O use concentration is 400~450ppm, H 2 o 2 The use concentration is 80-120ppm, the reflux ratio of reflux water is 2-4:1, and catalyst A is used to treat different biochemical effluents (different biochemical effluents are the effluents of wastewater in different production fields after biochemical treatment, and their COD is different). Processing, the processing results are shown in the table below:

[0038]

[0039]

[0040] As can be seen from the results in the above table, under the optimal reaction conditions, the Fenton-like process of the present invention has a good treatment effect on biochemical effluents with different CODs, and the COD removal rate ...

Embodiment 3

[0042] This embodiment relates to the comparison of the treatment effects of the Fenton-like process of the present invention and the existing Fenton-like process on biochemical effluent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com