A kind of treatment method of oil refining alkali residue waste liquid

A technology for refining alkali residue and treatment method, applied in combustion methods, chemical instruments and methods, water/sewage multi-stage treatment, etc. Efficient removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

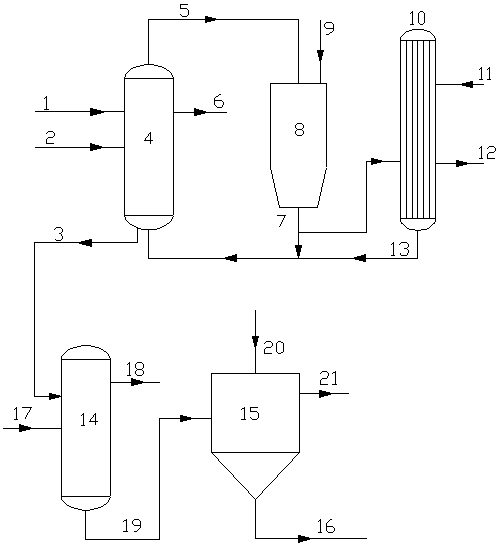

Embodiment 1

[0035] Catalytic gasoline alkali residue in a refinery, where COD is 3.21×10 5 mg / L, sulfide is 1.76×10 4 mg / L, volatile 1.07×10 5 mg / L. The method of the present invention is used for acidification treatment. First, concentrated sulfuric acid is introduced for acidification, and a certain amount of nitrogen is introduced for blowing off. When the pH value of the alkali residue in the acidification reactor is reduced to 13.5, the addition of concentrated sulfuric acid is stopped. The acidification tail gas produced by the acidification is passed into the incinerator for incineration, and at the same time, combustion-supporting oxygen is passed into the incinerator. The amount of oxygen introduced is 3 times the theoretical combustion oxygen demand of the acidification tail gas. The generated high-temperature acid gas first enters the acidification reactor to acidify the alkali slag, and when the temperature in the alkali slag waste liquid is higher than 80 ℃, it is passed into t...

Embodiment 2

[0038] Liquid hydrocarbon alkali residue of a refinery, where COD is 7.97×10 4 mg / L, sulfide is 4×10 3 mg / L, volatile phenol 1.4×10 4 mg / L. Use the method of the present invention to carry out the acidification treatment, firstly pass the gas acidification reagent SO 2 Carry out acidification and blow in a certain amount of nitrogen to blow off, reduce the pH value of the alkali residue in the acidification reactor to 13, and stop adding SO 2 . The acidification tail gas produced by acidification is passed into the incinerator for incineration, and at the same time, combustion-supporting oxygen is passed into the incinerator. The amount of oxygen introduced is 5 times the theoretical combustion oxygen demand of the acidification tail gas. The generated high-temperature acid gas first enters the acidification reactor to acidify the alkali slag. When the temperature of the alkali slag waste liquid is higher than 60°C, it is passed into the waste heat boiler to produce steam, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com