Silicon material a for hydrogen gas production, silicon material b for hydrogen gas production, method for producing silicon material a for hydrogen gas production, method for producing silicon material b for hydrogen gas production, method for producing hydrogen gas, and device for producing hydrogen gas

A production method and technology for silicon raw materials, which are applied to silicon raw material A for hydrogen production, silicon raw material B for hydrogen production, production of silicon raw material A for hydrogen production, production of silicon raw material B for hydrogen production, hydrogen production, and hydrogen production equipment It can solve problems such as difficulty in controlling hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

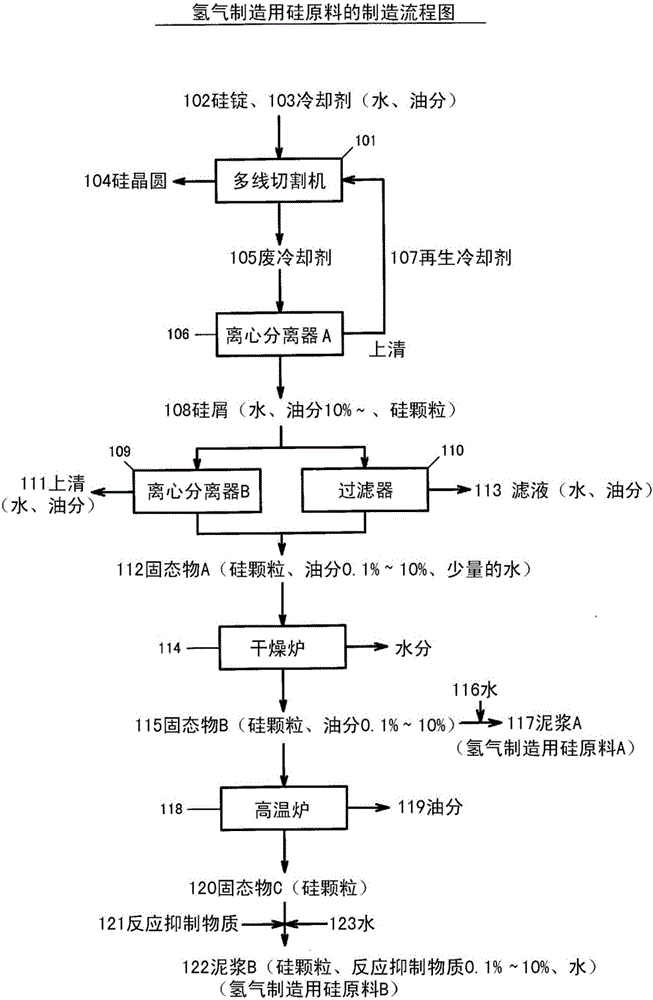

[0173] [Manufacture of silicon raw material A for hydrogen production]

[0174] As a coolant, a liquid mixture of 90% by weight of water and 10% by weight of propylene glycol was used. Using this coolant, silicon ingots are cut with a wire saw to produce silicon wafers. The shavings contained in the waste coolant were silicon particles with an average particle diameter of 1 μm. The waste coolant was centrifuged with centrifugal separator A (2500rpm).

[0175] Next, the silicon chips were centrifuged with a centrifuge B (3000 rpm) to obtain a solid A, and then the solid A was dried in a drying oven at 105° C. to obtain a solid B. The composition of the solid B was 97% by weight of silicon particles and 3% by weight of propylene glycol. In this way, by adjusting the amount of oil contained in the coolant 103 as the starting material and the rotational speed of the centrifugal separator B, the amount of oil contained in the solid matter B can be a desired value (0.1 wt. % to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com