In-situ chemical oxidation repair system and method for underground water polluted by hydrochloric ether

An in-situ chemical oxidation and repair method technology, which is applied in the field of in-situ chemical oxidation repair system for chlorinated hydrocarbon pollution in groundwater, can solve problems such as no waste gas collection system and secondary pollution, and achieve improved repair efficiency and increased oxidation capacity , Increase the effect of hydroxyl radicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

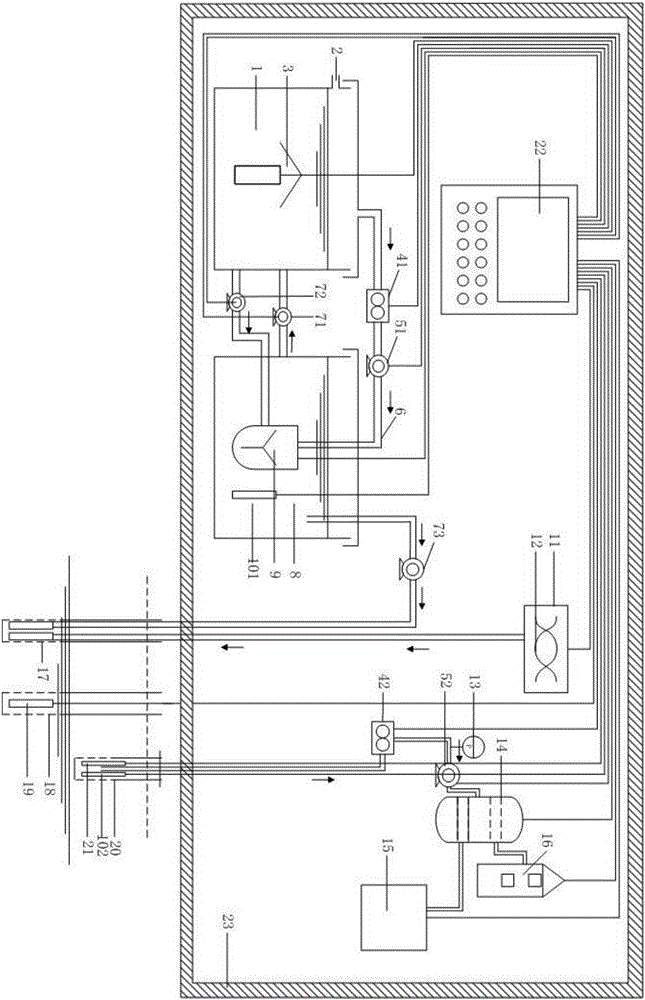

[0044] In a specific embodiment, the method includes the steps of:

[0045] (1) Ozone preparation step: prepare ozone gas;

[0046] (2) Micro-nano ozone bubble water forming step: the ozone gas prepared in step (1) is formed into micro-nano bubble water, and is circulated with step (1) until the ozone concentration in the micro-nano bubble water reaches a specified range, and it is used for Remediation of chlorinated hydrocarbons in groundwater;

[0047] (3) Strengthening agent injection step: when the micro-nano ozone bubble water prepared in step (2) is injected into the groundwater, the strengthening agent is injected into the groundwater at the same time; and

[0048] (4) Waste gas collection and treatment steps: when the organic pollutant gas in soil and groundwater exceeds 1000mg / m 3 , for waste gas collection and treatment.

[0049] In a preferred embodiment, the specified range of the ozone concentration in the micro-nano bubble water in the method step (2) is 1 mg / ...

Embodiment 1

[0074] The method of in-situ oxidation remediation of groundwater contaminated by chlorinated hydrocarbons was used to remediate the groundwater polluted by high concentration of chlorinated hydrocarbons in a pesticide factory in the south. The site can be divided into artificial filling layer and Quaternary sedimentary layer from top to bottom. The artificial fill layer includes miscellaneous fill and plain fill. The thickness of miscellaneous fill is 0.3-2m, with an average thickness of 1m. The thickness of plain fill is 0.5-3.6m, with an average thickness of 1.9m. There are two layers of silty clay and silt, the upper layer is uniform in soil quality, and the lower layer contains more gravel particles, formed by slope accumulation, the silty clay layer is 0.3-7.4m thick, and the silt layer is 0.5-1.8m thick; the bedrock of the site includes mudstone, There are three types of shale and conglomerate, and the bedrock exposure depth varies from 1.2 to 8.1m. The groundwater in ...

Embodiment 2

[0076] In the same site as in Example 1, in areas with similar groundwater hydrogeological conditions and pollution concentrations, micro-nano ozone bubble water was used to remediate groundwater pollution. at 50m 2One injection well, two monitoring wells and two extraction wells are arranged in the groundwater polluted area. The average depth of the injection wells and monitoring wells is 4.3 meters. The well depth of the gas extraction well is 1 meter, the depth of opening the screen is 0.3 meters underground, and the length is 0.5 meters.

[0077] Start the ozone generator and the micro-nano ozone bubble water generator. When the ozone concentration reaches 1.5mg / L and the micro-nano bubble size is 60nm to 50μm, inject micro-nano ozone bubble water into the injection well every day. Nano-ozone bubble water, when the dissolved oxygen in the monitoring well rises significantly, use the enhancer injection tank to configure 5% H 2 o 2 , injected into the injection well. Dur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com