Glycerol alkyl ether production method and production device based on heterogeneous catalysis

A technology of glycerin alkyl ether and production method, which is applied in the fields of dehydration of hydroxyl-containing compounds to prepare ether, ether preparation, organic chemistry, etc., and can solve problems such as large labor input, reduced conversion rate of raw materials, unfavorable environmental protection, and efficient utilization of resource recycling , to achieve the effect of prolonging the service life and improving the reaction conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

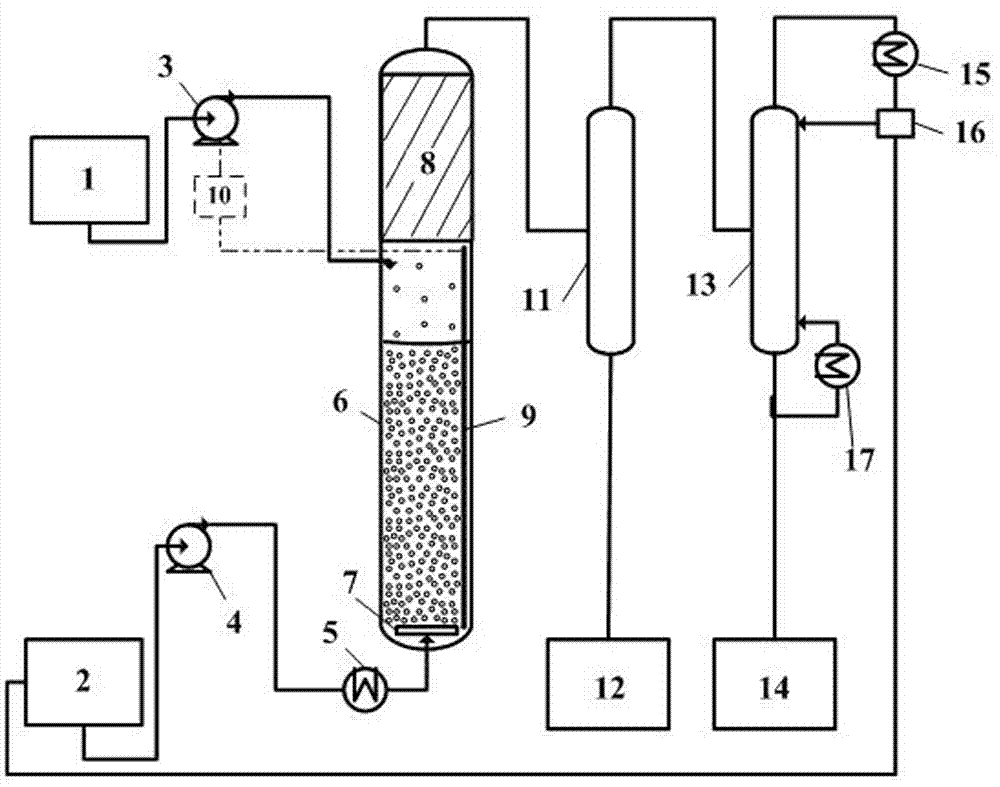

[0054] The structure of glycerol alkyl ether production plant is as follows figure 1 , mainly composed of glycerin storage tank 1, low-carbon alcohol storage tank 2, bubble column reactor 6, flash distillation column 11 and rectification column 13 and so on.

[0055] The upper part of the bubble column reactor 6 is provided with a packing reflux demister 8, the middle and lower part is a reaction zone, and a gas distributor 7 is set at the bottom of the tower; the packing reflux demister 8 is filled with regular or bulk packing, and the reaction zone is The solid alcohol dehydration catalyst is filled with a liquid level sensor 9, which is electrically connected to the glycerol feed pump 3 through a liquid level controller 10; Below the foamer, a gas-phase feed port is arranged at the bottom of the reactor, communicated with the gas distributor, and a reaction material outlet is arranged at the top of the reactor.

[0056] The liquid glycerin storage tank 1 is connected to th...

Embodiment 2

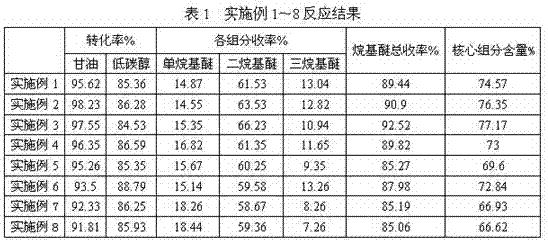

[0060] The production device is the same as that of Example 1. The reactor was filled with catalyst MCM-22 with a particle size of 200 meshes. The ethanol and glycerol were pumped into the reactor according to the liquid volume flow ratio of 5:1, and the mass space velocity of ethanol was controlled to be 3h. -1 . Among them, ethanol is preheated to 79 ℃ through a heat exchanger and then gasified before entering the reactor, and glycerol is directly fed into the reactor. The reaction temperature in the reactor was set to 225°C and the pressure was 0.3Mpa; the feed temperature of the flash tower was 220°C and the flash pressure was 0.3Mpa; the feed temperature of the rectification tower was 115°C and the reflux ratio was 3. The experimental results are shown in Table 1.

Embodiment 3

[0062] The production device is the same as that of Example 1. The reactor was filled with catalyst MCM-41 with a particle size of 200 meshes. Turn on the liquid feed pump in turn, pump n-propanol and glycerol into the reactor according to the liquid volume flow ratio of 5:1, and control the mass space velocity of n-propanol to be 3h -1 . The n-propanol is preheated to 98 ℃ through a heat exchanger and then gasified before entering the reactor, and the glycerol is directly fed into the reactor. The reaction temperature in the reactor was set to 245°C and the pressure was 0.3Mpa; the feed temperature of the flash tower was 230°C and the flash pressure was 0.3Mpa; the feed temperature of the rectification tower was 130°C and the reflux ratio was 5. The experimental results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com