High static pressure and enzyme hydrolysis combined method for preparing hypoallergenic ginkgo protein powder

A technology with high static pressure combined with enzymes, applied in food science, fermentation, etc., to achieve the effects of high safety, good solubility, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] High static pressure treatment of ginkgo protein

[0034] Take a certain amount of ginkgo protein, prepare a ginkgo protein solution with a concentration of 40-60 mg / mL with distilled water, seal it in a double-layer polyethylene plastic bag, vacuum seal it, put it in a high-pressure device, and store it at 25°C. Under high static pressure treatment, the treatment pressure range is 100-700MPa, and the treatment time is 20-30min.

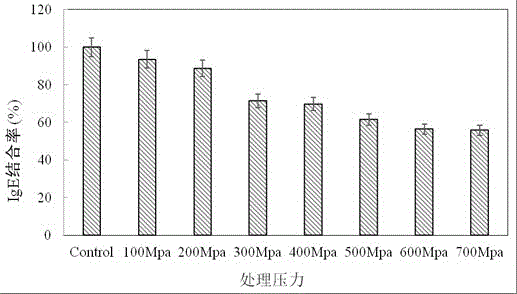

[0035] The present invention studies the influence of different treatment pressures on the sensitization of ginkgo protein. 50 g of ginkgo protein is taken respectively, and distilled water is used to prepare a ginkgo protein solution with a concentration of 50 mg / mL, which are respectively sealed in double-layer polyethylene plastic bags, and pumped out. After being vacuum-sealed, place it in a high-pressure equipment, and use 100, 200, 300, 400, 500, 600, and 700 MPa to perform high-static pressure treatment at 25°C for 20 minutes, and then us...

Embodiment 2

[0038] Protease Hydrolysis of Ginkgo Protein

[0039] Take a certain amount of high-pressure-treated ginkgo protein sample, heat-treat it at 90°C for 5 minutes, and then use 1mol / L HCl or 1mol / L NaOH to adjust the pH value of the solution to the optimum hydrolysis pH for protease. According to the quality of ginkgo protein sample, press 1~ Add protease to 5% mass ratio for hydrolysis. The hydrolysis temperature is the optimum hydrolysis temperature of protease. The hydrolysis time is 1-2 hours. After hydrolysis, the enzyme activity is inactivated at 95°C for 10 minutes. Ginkgo protein powder.

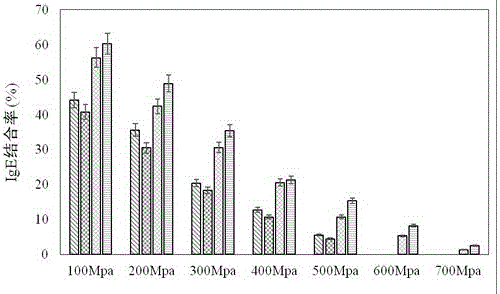

[0040] The protease is one of alkaline protease, papain, pepsin or neutral protease.

[0041] The optimum hydrolysis pH of the protease is pH 8.0 for alkaline protease, pH 6.5 for papain, pH 1.5 for pepsin and pH 7.0 for neutral protease.

[0042] The optimum hydrolysis temperature for protease is 45°C for alkaline protease, 55°C for papain, 40°C for pepsin and 45°C for neutral protea...

Embodiment 3

[0046] Preparation of Hypoallergenic Ginkgo Protein Powder

[0047] (1) Separation and purification of ginkgo protein

[0048] Take 1kg of fresh ginkgo fruit, shell them, freeze-dry them, grind and sieve them, and degrease them with petroleum ether until the degreasing is complete. After the petroleum ether is completely volatilized, add pH7.4 at a ratio of 1:15g / mL to a concentration of 0.2mol / L The Tris-HCl solution was used for protein extraction, magnetically stirred at 4°C for 24h, then refrigerated and centrifuged at 5000r / min for 15min at 4°C, and the supernatant was passed through 40 and 80g / 100mL saturated (NH4) 2 SO 4 Carry out fractional precipitation, refrigerate and centrifuge at 5000r / min for 30min at 4°C, dissolve the precipitate with a small amount of Tris-HCl solution with a concentration of 0.01mol / L at pH 8.0, place it in a dialysis bag with a molecular weight cut-off of 3.5kDa and use the same Tris- HCl solution was dialyzed, and after the dialysate was f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com