Optical film comprising primer layer containing polyester resin and polarizing plate using same

一种聚酯树脂、光学膜的技术,应用在偏光板领域,能够解决低折射率、损坏、降低偏光板性能等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

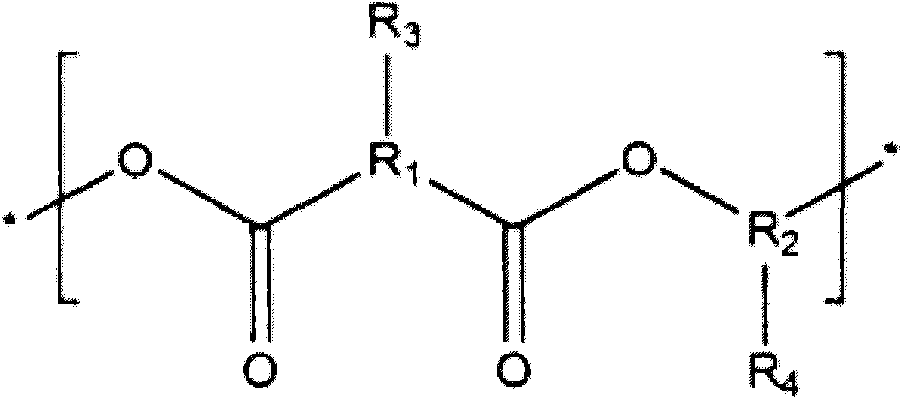

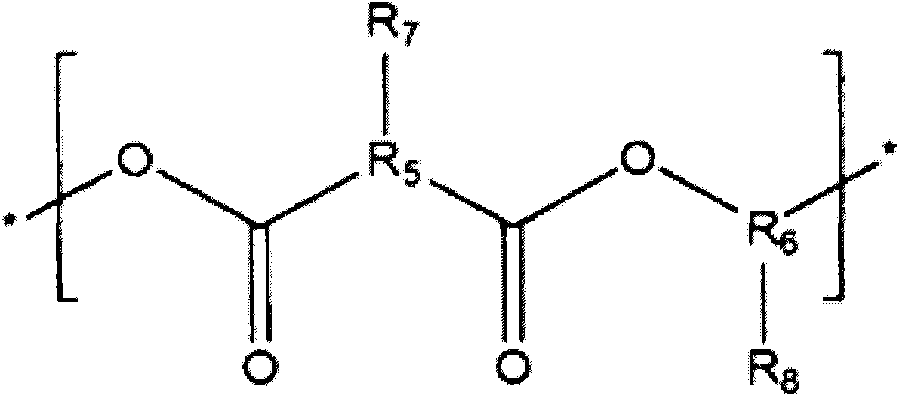

Method used

Image

Examples

preparation Embodiment 1

[0110] Preparation Example 1 - Preparation of a composition for forming a functional coating

[0111] 18 g of pentaerythritol triacrylate and 18 g of dipentaerythritol pentaacrylate as binder resin; 250 g of hollow silica particle dispersion solution (produced by Catalystand Chemicals Co., Ltd., hollow silica particles with a number average particle size of 50-60 nm in 20 wt % 10g of polyether siloxane polymer (produced by EVONIKInd., trade name: TEGOGlide450) particles; and 4g of light A polymerization initiator (manufactured by CIBA Specialty Chemicals, trade name: Irgacure 184) was mixed and stirred for 30 minutes. Here, it was diluted with methyl isobutyl ketone (MIBK) so that the solid content was 3 wt%, to prepare a low reflection coating composition.

preparation Embodiment 2

[0112] The preparation of preparation example 2-polyester resin

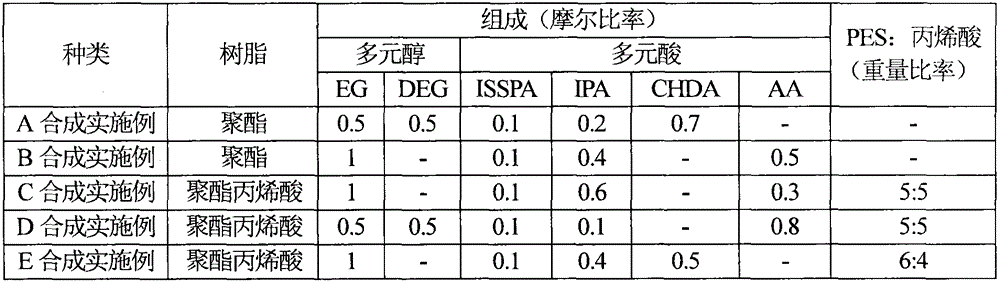

[0113] (1) Synthesis Example of Polyester Resin A

[0114] The 500 ml round bottom flask was replaced with nitrogen, and ethylene glycol (EG), diethylene glycol (DEG), m-benzene Sodium sulfonate dicarboxylate (SSIPA), isophthalic acid (IPA) and cyclohexanedicarboxylic acid (CHDA), were esterified at 200°C for 2 hours to remove the theoretical amount of water. Add tetramethyl titanate, antimony acetate, and dibutyltin oxide as a catalyst, and trimethyl phosphate as a stabilizer to continuously remove water, and then carry out polycondensation at 255°C under a reduced pressure of 2.5 torr or less React for 150 minutes to prepare polyester resin A.

[0115] (2) Synthesis Example of Polyester Resin B

[0116] The 500 ml round bottom flask was replaced with nitrogen, and ethylene glycol (EG), diethylene glycol (DEG), m-benzene Sodium sulfonate dicarboxylate (SSIPA), isophthalic acid (IPA) and adipic acid (AA), we...

Embodiment 1

[0126] After mixing 40 parts by weight of polyester resin A produced as described above, 3 parts by weight of silica, and 57 parts by weight of water to produce a primer composition, the primer composition was coated onto an electric wire by #7 bar. on one surface of a halo-treated acrylic-based film, and the film was uniaxially stretched in the MD direction at 135°C, and then uniaxially stretched in the TD direction to produce a film in which the primer layer was formed with a thickness of 600 nm. Acrylic based film. The surface of the membrane is at 50W / m 2 / min under the conditions of corona treatment.

[0127] The composition for forming a functional coating produced by Preparation Example 1 was applied to the surface of the prepared primer layer-coated film by using a bar coating method so that the thickness after drying was 4 μm, and then irradiated at 280 mJ / cm 2 UV to carry out curing, and thus obtain a film formed with a functional coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com