Butylene oxy-dehydrogenation catalyst for fluidized bed and preparation method therefor

A technology for oxidative dehydrogenation and catalyst, applied in the field of catalysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

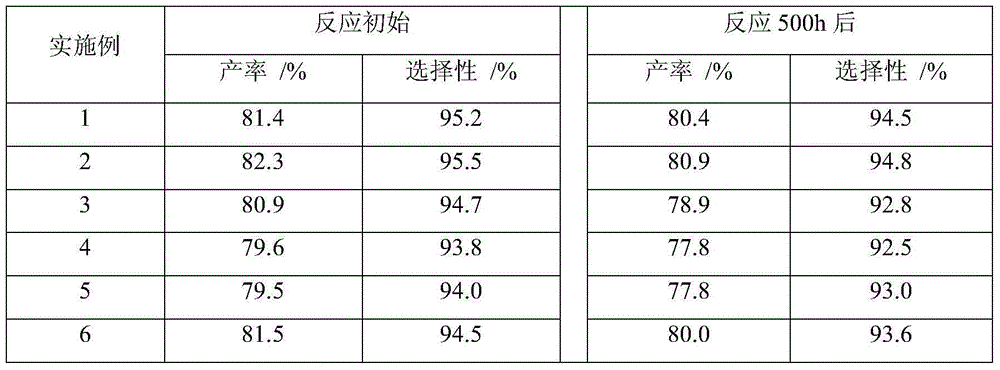

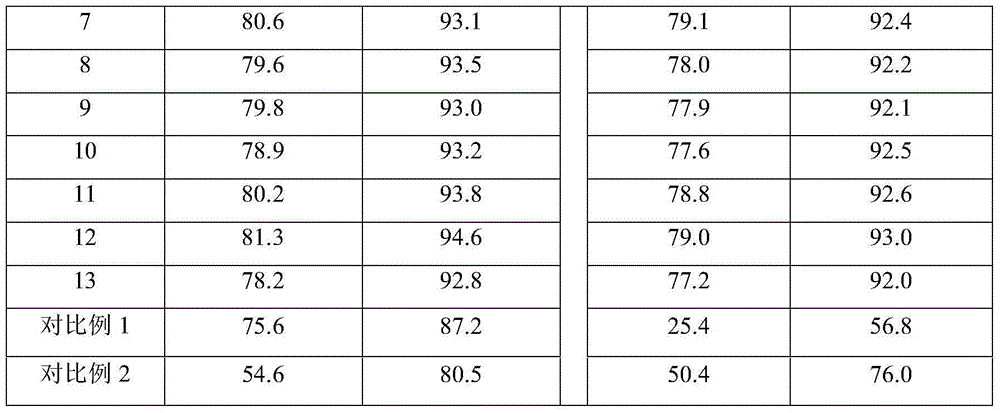

Examples

Embodiment 1

[0038] (1) First, grind the used metal precursor A chromium nitrate 1200g, B cobalt nitrate 29g, C calcium chloride 44g, D tungsten trioxide 7g into 50 mesh microspheres; secondly, metal precursor A chromium nitrate by 60 % and 40% are divided into two parts of 720g and 480g, and cobalt nitrate, magnesium chloride, nickel nitrate are mixed evenly;

[0039] (2) configure 20L0.45mol / L ferric nitrate solution, under stirring condition, earlier 163g copper nitrate is added in the ferric nitrate solution gradually, react for 40 minutes, then slowly add the mixture of cobalt nitrate, magnesium chloride, nickel nitrate, react After 90 minutes, slowly add 109g of zinc nitrate, and add 100g of methylcellulose after 40 minutes of reaction;

[0040] (3) After stirring for 30 minutes, add 20% ammonia water dropwise to the slurry to adjust the pH value of the slurry to 9.0;

[0041] (4) thermally modifying the slurry at a constant temperature of 85° C. for 90 minutes;

[0042] (5) Wash t...

Embodiment 2

[0045] Catalyst preparation process is according to embodiment 1, configures 20L0.6mol / L ferric nitrate solution, the metal precursor is ground into 100 mesh microspheres, precursor A is divided into two parts of 60% and 40%, add the metal precursor two intervals The reaction time was 70 minutes and 60 minutes respectively, and the dosage of each metal precursor was: 1190 g of zinc nitrate, 45 g of nickel nitrate, 80.8 g of magnesium chloride, and 10 g of tungsten trioxide. After reacting for 40 minutes, 94 g of scallop powder was added. After stirring for 30 minutes, 15% ammonia water was added dropwise to the slurry to adjust the pH of the slurry to 8.0, and the slurry was thermally modified at a constant temperature of 80° C. for 90 minutes. The slurry was washed with tap water to bring the pH of the slurry to 7.5. Filter the slurry, and bake the filter cake at 160° C. for 10 hours for modification. Calcination modification was carried out at 280°C for 6 hours, at 370°C f...

Embodiment 3

[0047] Catalyst preparation process is according to embodiment 1, configures 20L0.3mol / L ferric nitrate solution, the metal precursor is ground into 80 mesh microspheres, precursor A is divided into two parts of 65% and 35%, add the metal precursor two intervals The reaction time is 50 minutes and 70 minutes respectively, and the dosage of each metal precursor is: copper sulfate 622g, manganese sulfate 34g, barium oxide 104g, tungsten trioxide 2.5g. After reacting for 40 minutes, 70 g of polyacrylamide was added. After stirring for 30 minutes, 25% ammonia water was added dropwise to the slurry to adjust the pH value of the slurry to 8.5, and the slurry was thermally modified at a constant temperature of 90° C. for 90 minutes. Wash the slurry with desalinated water to make the pH of the slurry reach 7.2. Filter the slurry, and bake the filter cake at 140° C. for 12 hours for modification. Calcination modification at 220°C for 12 hours, calcining modification at 340°C for 2 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com