a spherical ti 2 nb 10 o 29 Materials and methods of making the same

A spherical, certain amount of technology, applied in the direction of chemical instruments and methods, hybrid/electric double layer capacitor manufacturing, niobium compounds, etc., can solve the problem of long diffusion path of lithium ions, low electrochemical rate performance, large particle size of titanium niobate, etc. problems, to achieve the effect of easy control of product size, high rate cycle performance, and uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (a) dissolving niobium pentachloride in a certain amount of glacial acetic acid, then adding titanium sulfate according to the atomic ratio titanium / niobium=0.18 under stirring conditions, wherein the concentration of niobium ions is 0.26mol / L;

[0031] (b) Put the mixed solution obtained in step (a) into a stainless steel reaction kettle lined with polytetrafluoroethylene, place it in a constant temperature drying oven, and react at 260° C. for 36 hours;

[0032] (c) naturally cooling to room temperature, washing the obtained precipitate three times with deionized water and ethanol respectively, and then vacuum-drying at 75° C. to obtain a powder;

[0033] (d) Calcining the powder obtained in step (c) at 1230°C for 30 hours to obtain spherical Ti 2 Nb 10 o 29 Material.

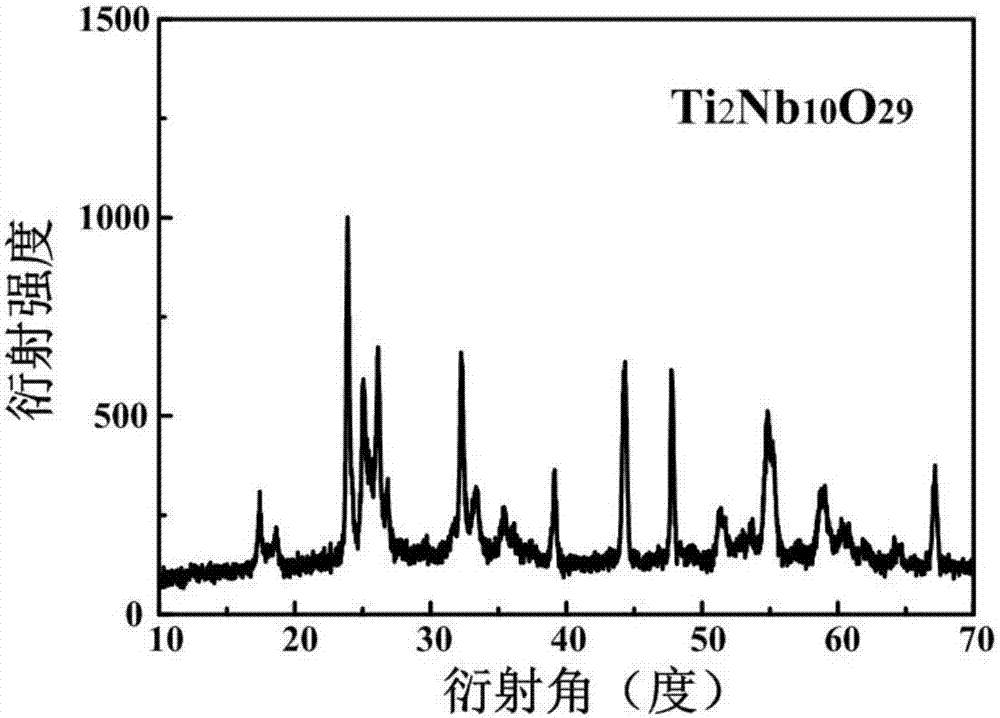

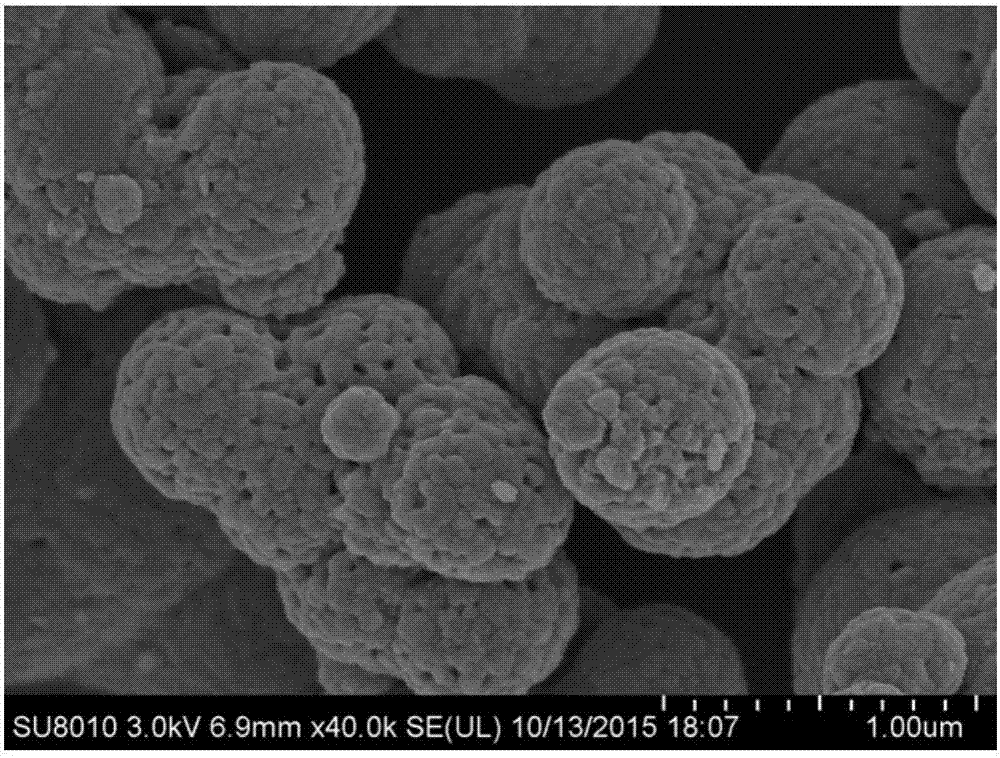

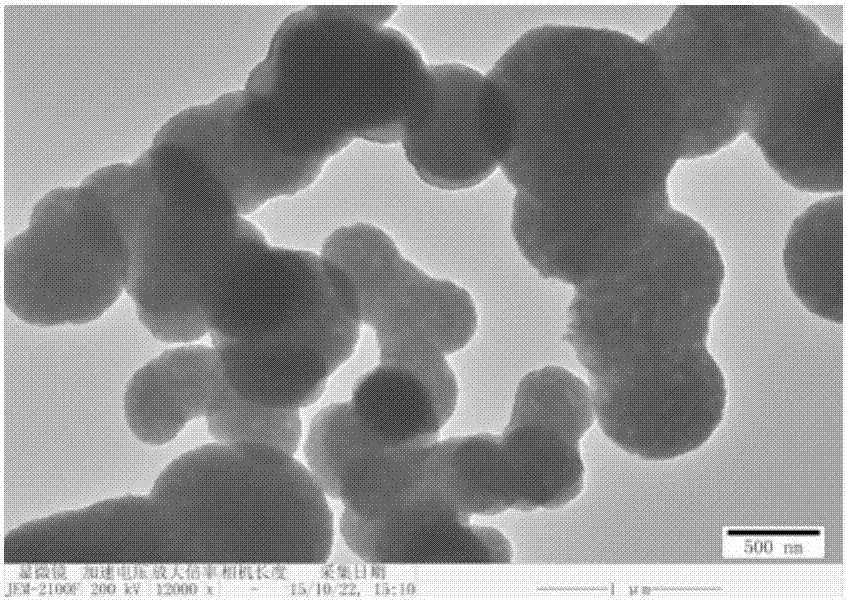

[0034] Spherical Ti prepared by Example 1 2 Nb 10 o 29 The XRD pattern of the material is shown in figure 1 As shown, the diffraction peak of the sample is the same as that of Ti in the standard...

Embodiment 2

[0036] (a) dissolving niobium ethanol in a certain amount of glacial acetic acid, and then adding butyl titanate according to the atomic ratio titanium / niobium=0.23 under stirring conditions, wherein the concentration of niobium ions is 2.1mol / L;

[0037] (b) Put the mixed solution obtained in step (a) into a stainless steel reaction kettle lined with polytetrafluoroethylene, place it in a constant temperature drying oven, and react at 120° C. for 72 hours;

[0038] (c) naturally cool to room temperature, wash the obtained precipitate three times with deionized water and ethanol, and then vacuum-dry at 70° C. to obtain a powder;

[0039] (d) Calcining the powder obtained in step (c) at 1110°C for 40 hours to obtain spherical Ti 2 Nb 10 o 29Material.

Embodiment 3

[0041] (a) dissolving niobium oxalate in a certain amount of glacial acetic acid, then adding titanium sulfate according to the atomic ratio titanium / niobium=0.21 under stirring conditions, wherein the concentration of niobium ions is 0.0015mol / L;

[0042] (b) Put the mixed solution obtained in step (a) into a stainless steel reaction kettle lined with polytetrafluoroethylene, place it in a constant temperature drying oven, and react at 280° C. for 30 hours;

[0043] (c) naturally cooling to room temperature, washing the obtained precipitate three times with deionized water and ethanol respectively, and then vacuum-drying at 96° C. to obtain a powder;

[0044] (d) Calcining the powder obtained in step (c) at 710°C for 60 hours to obtain spherical Ti 2 Nb 10 o 29 Material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com