Dielectric ceramic material with giant dielectric constant and low dielectric loss and method for preparing dielectric ceramic material

A technology of giant dielectric constant and ceramic materials, applied in the field of information functional materials, can solve the problems of large dielectric loss and limitation, and achieve the effects of low dielectric loss, suppression of relaxation, excellent temperature and frequency stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

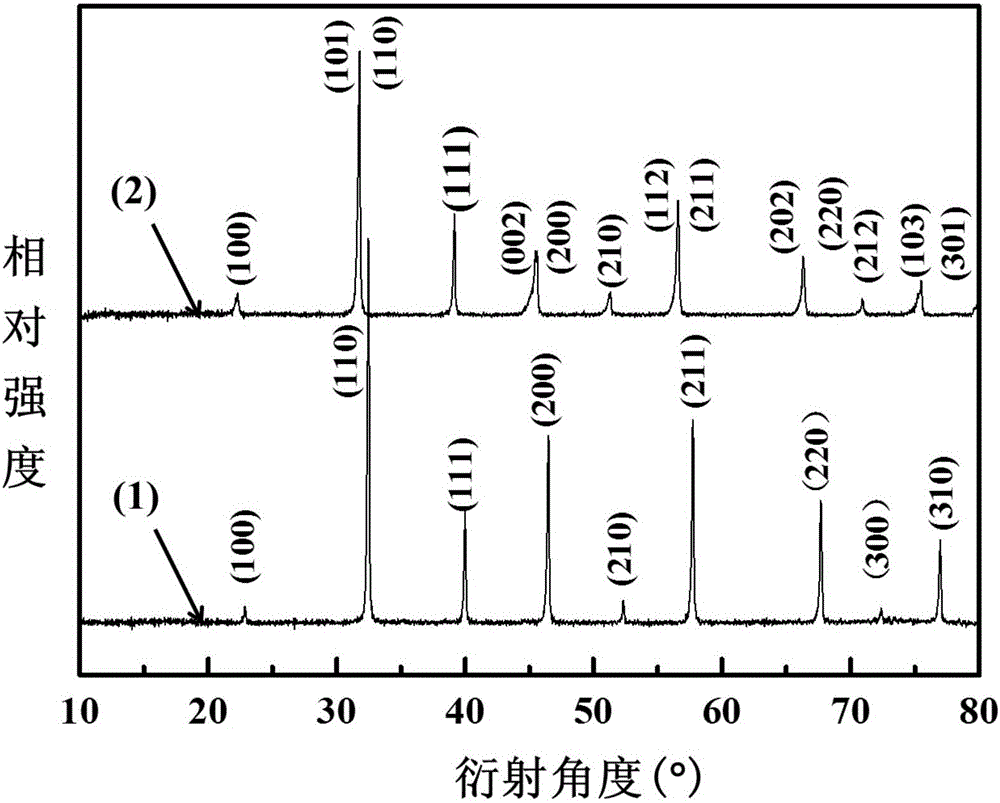

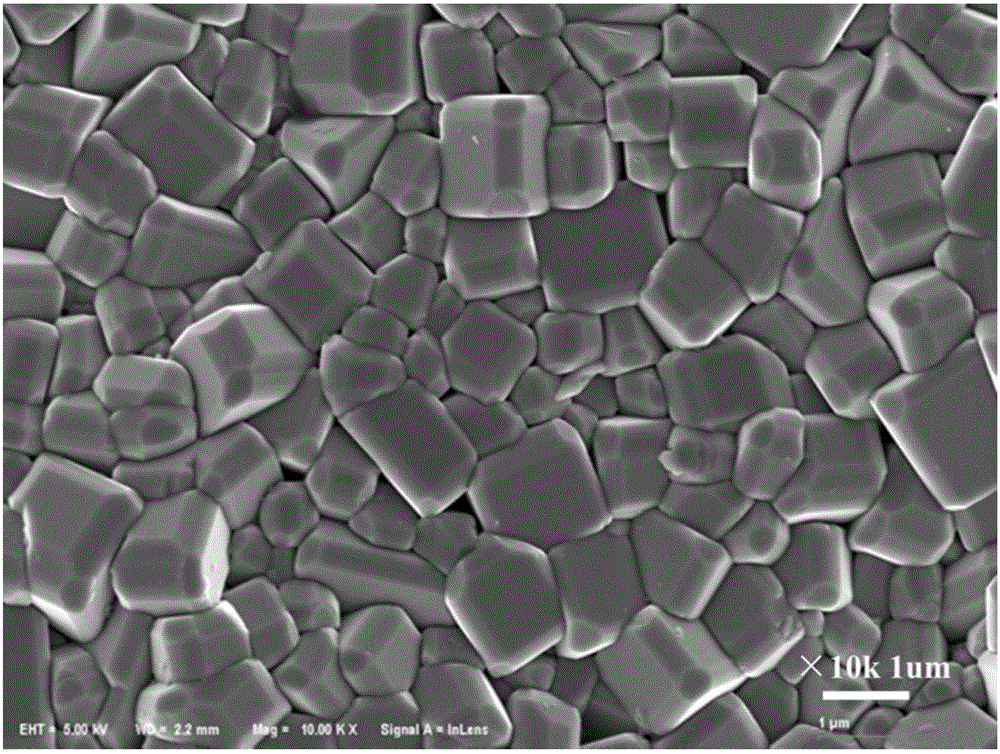

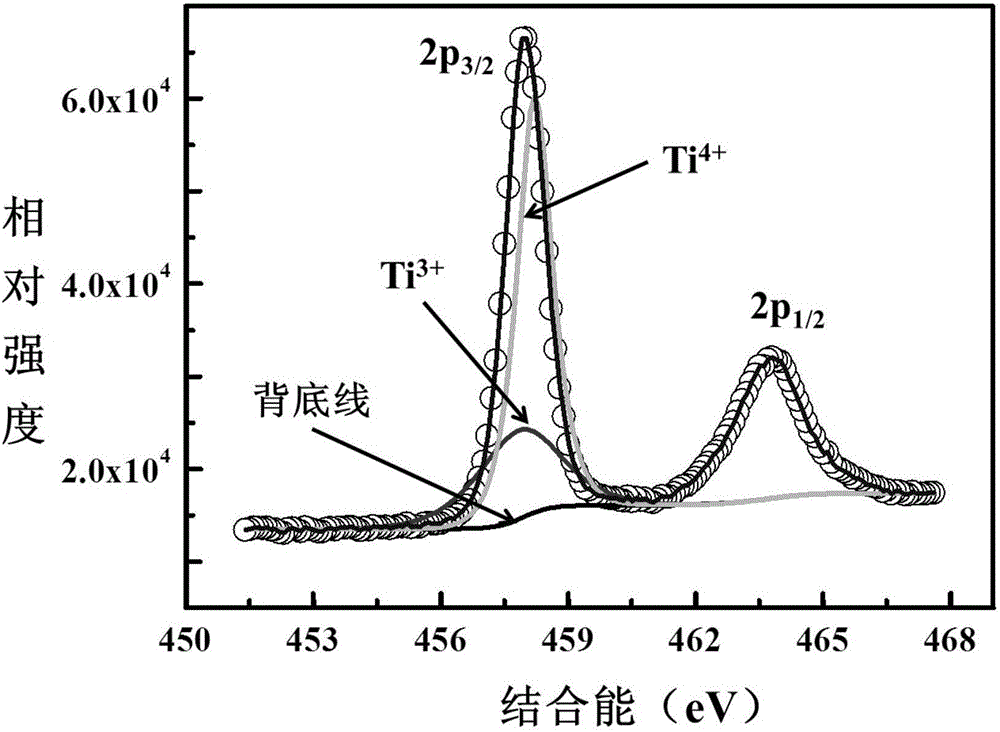

[0039] A dielectric ceramic material (Ba 0.2 Sr 0.77 SM 0.02 TiO 3 , label is BSST-28), its preparation method comprises the steps:

[0040] 1) with BaCO 3 , SrCO 3 、Sm 2 o 3 and TiO 2 As raw material, according to Ba 0.2 Sr 0.77 SM 0.02 TiO 3 The stoichiometric ratio of each raw material is selected, a total of 30g, the resulting mixed raw materials are put into a ball mill jar, and zirconium balls and absolute ethanol are used as the medium, and the ball milling rate is 900r / min. After ball milling for 24 hours, put it into a drying oven for drying , the oven temperature is set to 100°C, and the drying time is 24 hours;

[0041] 2) After drying, the mixture obtained was pre-fired at 1150° C. in an air atmosphere for 2 hours, and the pre-fired powder was subjected to secondary ball milling to obtain a pre-fired powder. The secondary ball milling process was consistent with the ball milling process described in step 1);

[0042] 3) Add the calcined powder to a bin...

Embodiment 2

[0048] A dielectric ceramic material (Ba 0.4 Sr 0.57 SM 0.02 TiO 3 , label is BSST-46), its preparation method is roughly the same as Example 1, and the difference is: by Ba 0.4 Sr 0.57 SM 0.02 TiO 3 The stoichiometric ratio of (BSST-46) selects each raw material; the ball milling time is 30 hours, the ball milling speed is 800r / min; the drying oven temperature is set at 100°C, and the drying time is 30 hours; Hours; the second ball milling time is 30h, the ball milling speed is 800r / min; the uniaxial pressure is 10MPa; after repeated vacuuming the pipeline in the sintering furnace for 4 times, the nitrogen gas flow is continued, and the nitrogen flow rate is 100mL / min; the sintering process The temperature system is as follows: first raise the temperature to 1000°C at a heating rate of 6°C / min, then raise the temperature to 1450°C at a heating rate of 3°C / min and keep it for 3 hours, and then cool down to 3°C / min during the sintered ceramic cooling process. After 1000°...

Embodiment 3

[0051] A dielectric ceramic material (Ba 0.1 Sr 0.87 SM 0.02 TiO 3 , label is BSST-19), and its preparation method is roughly the same as Example 1, except that: press Ba 0.1 Sr 0.87 SM 0.02 TiO 3 The stoichiometric ratio of (BSST-19) selects each raw material; the ball milling time is 18 hours, and the ball milling speed is 1000r / min; the pre-burning temperature is 1180°C, and the time is 2.5 hours; the secondary ball milling time is 18h, and the ball milling speed is 1000r / min; In the gas washing process before nitrogen-assisted sintering, the nitrogen gas was continuously pumped and vacuumed 8 times, and nitrogen gas was continuously passed through the entire pipeline at a rate of 50mL / min, and the ceramic green body was sintered in a nitrogen atmosphere; the sintering process The specific temperature system is as follows: first raise the temperature to 1000°C at a heating rate of 8°C / min, then raise the temperature to 1550°C at a heating rate of 5°C / min and keep it f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com