Air-resistant antibacterial biological film, and preparation method and application thereof

A biofilm and gas-barrier technology, applied in the field of polymer materials, can solve the problems of lack of versatility and achieve excellent antibacterial properties, excellent gas-barrier properties, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the gas barrier and antibacterial biofilm of the present embodiment comprises the following steps:

[0031] (1) The TEMPO chemically pretreated nanocellulose is formulated into a dispersion liquid with a content of 1% (w / w) of cellulose evenly dispersed;

[0032] (2) dissolving chitosan with 2% acetic acid to prepare a solution with a chitosan content of 1% (w / w);

[0033] (3) the cellulose dispersion and the chitosan solution are evenly mixed, the weight ratio of the cellulose dispersion and the chitosan solution is 1: 0.1, the stirring speed is 1000rpm, the stirring time is 30 minutes, and the degassing is complete;

[0034] (4) Dewatering by model casting and coating, drying at 35°C to obtain a gas-barrier antibacterial biofilm with a film weight of 20 g / m 2 .

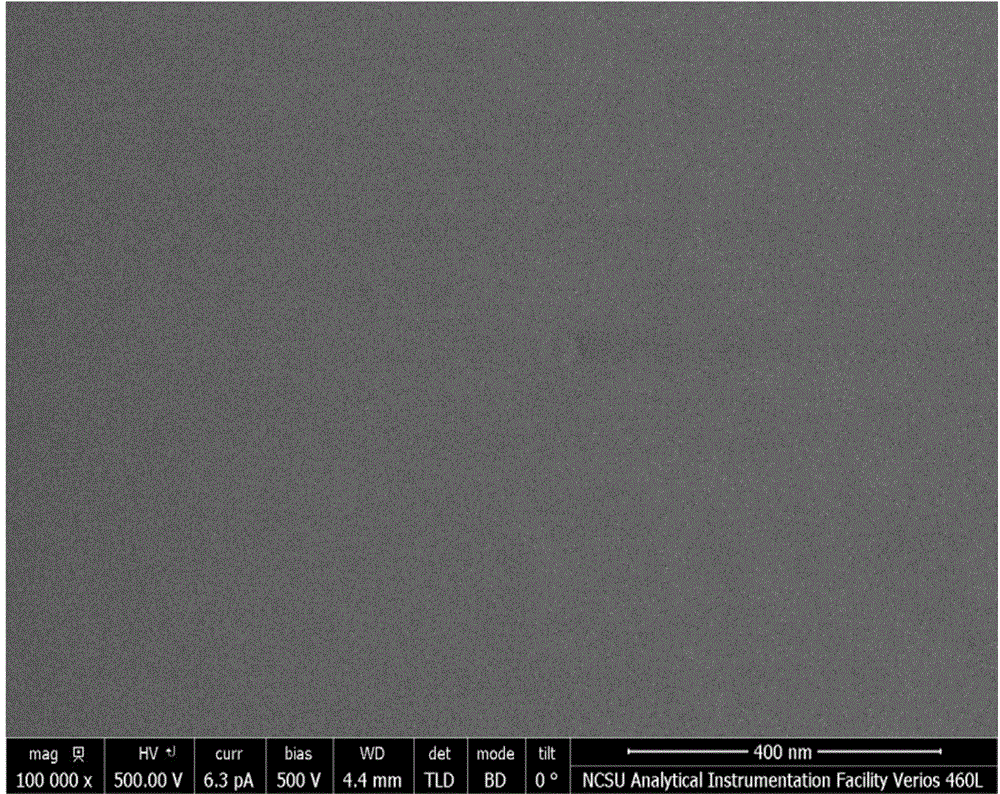

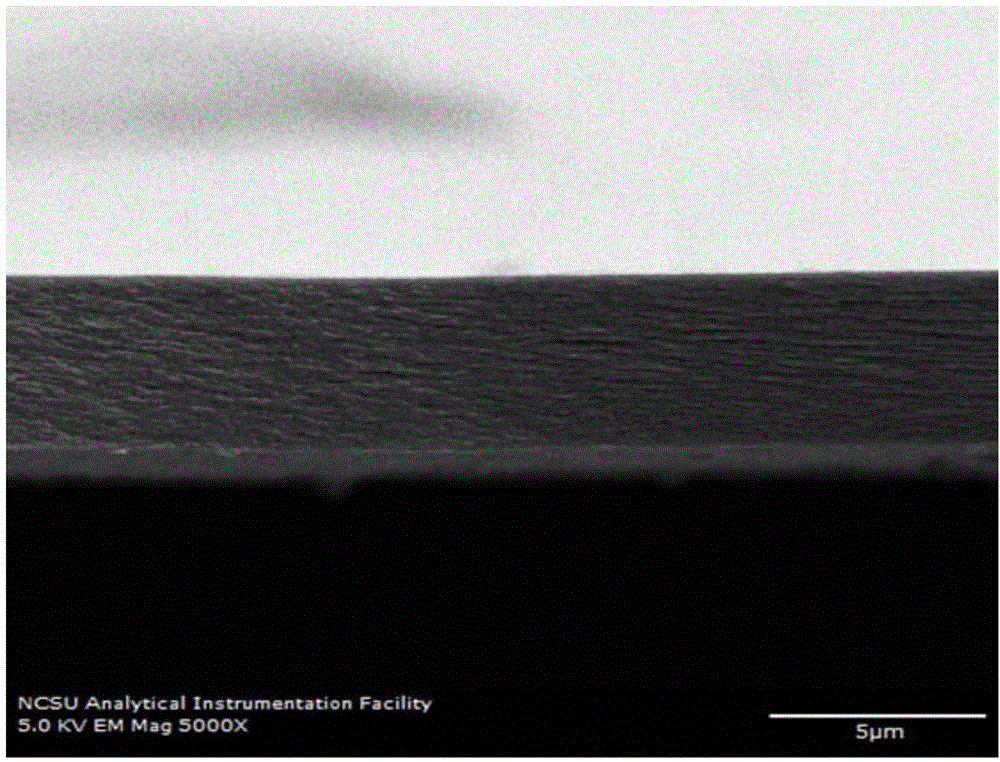

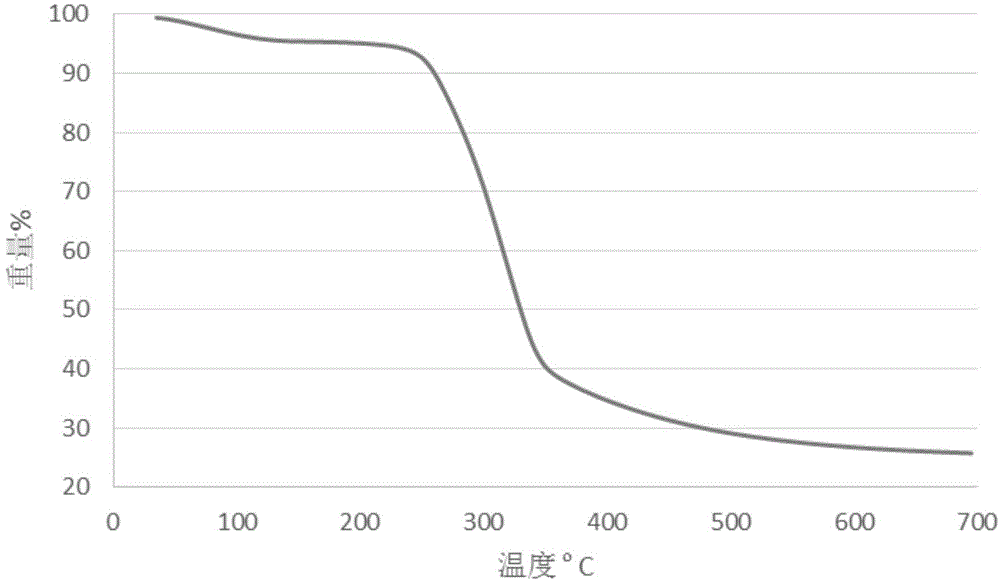

[0035] The morphology of the prepared gas-barrier antibacterial biofilm is as follows: figure 1 and figure 2 shown, by figure 1 and figure 2 It can be seen that the prepared ...

Embodiment 2

[0037] The preparation method of the gas barrier and antibacterial biofilm of the present embodiment includes the following steps:

[0038] (1) The nanocellulose pretreated with biological enzyme is formulated into a dispersion liquid with a content of 1% (w / w) of cellulose evenly dispersed;

[0039] (2) dissolving chitosan with 0.01mol / L hydrochloric acid to prepare a solution with a chitosan content of 1% (w / w);

[0040] (3) the cellulose dispersion and the chitosan solution are evenly mixed, the weight ratio of the cellulose dispersion and the chitosan solution is 1: 0.1, the stirring speed is 1000rpm, the stirring time is 30 minutes, and the degassing is complete;

[0041] (4) Dewatering by casting coating method of microporous membrane cushion layer, drying at 35°C, to obtain gas-barrier antibacterial biofilm, the membrane weight is 2g / m 2 .

[0042] The gas barrier results of the prepared gas barrier and antibacterial biofilms are shown in Table 1, and the antibacteria...

Embodiment 3

[0044] The preparation method of the gas barrier and antibacterial biofilm of the present embodiment includes the following steps:

[0045] (1) The TEMPO chemically pretreated nanocellulose is formulated into a dispersion liquid with a content of 1% (w / w) of cellulose evenly dispersed;

[0046] (2) dissolving chitosan with 2% acetic acid to prepare a solution with a chitosan content of 1% (w / w);

[0047] (3) the cellulose dispersion and the chitosan solution are evenly mixed, the weight ratio of the cellulose dispersion and the chitosan solution is 1: 0.05, the stirring speed is 1000rpm, the stirring time is 30 minutes, and the degassing is complete;

[0048] (4) Dehydration by pressure dehydration method, drying at 40°C, to obtain a gas-barrier antibacterial biofilm with a film weight of 20g / m 2 .

[0049] The gas barrier results of the prepared gas barrier and antibacterial biofilms are shown in Table 1, and the antibacterial results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com