Anti-ultraviolet spectacle lens and preparation process thereof

An anti-ultraviolet and preparation process technology, applied in the field of glasses, can solve the problems of not improving the anti-ultraviolet performance of spectacle lens materials, poor biocompatibility of anti-ultraviolet materials, easy falling off of anti-ultraviolet materials, etc., achieves good photochemical stability, improves anti-ultraviolet Excellent effect of aging ability and structural stability, anti-oxidation ability and anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

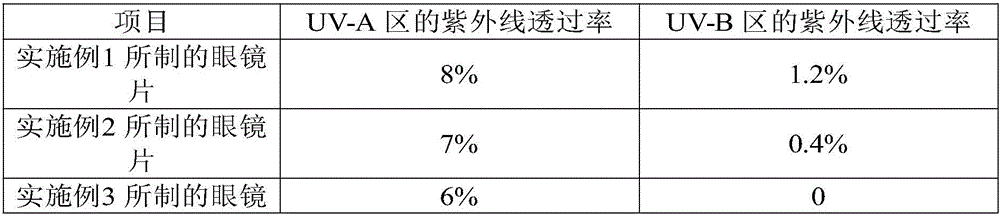

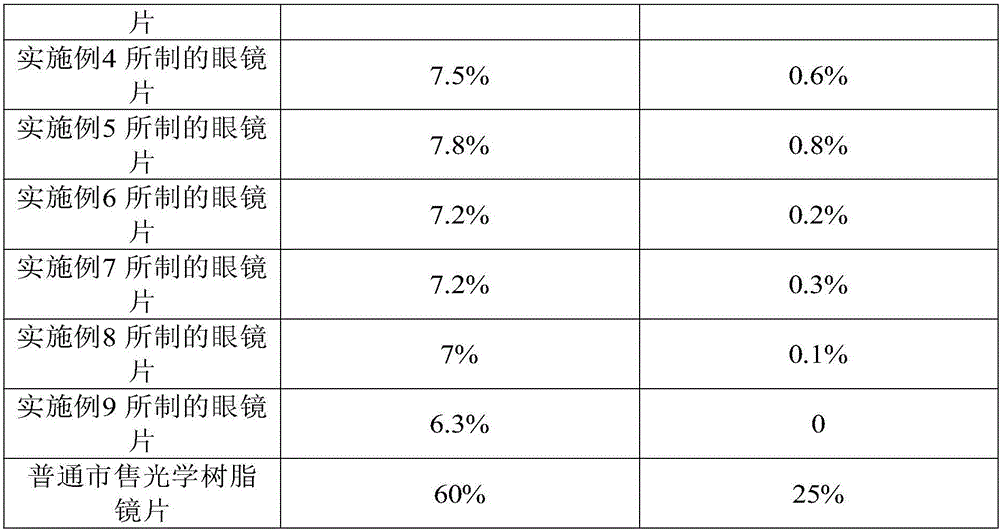

Embodiment 1

[0028] An anti-ultraviolet spectacle lens, the raw materials and weight percentages thereof for preparing the anti-ultraviolet spectacle lens are:

[0029] Poly(hydroxyethyl acrylate) 99.0%;

[0030] Light shielding agent: titanium dioxide 0.25%;

[0031] UV absorber: oxazoline ring 0.30%;

[0032] Free radical scavenger: Tetramethylpyridine 0.20%;

[0033] Compatibilizer: Oxazoline 0.25%.

Embodiment 2

[0035] An anti-ultraviolet spectacle lens, the raw materials and weight percentages thereof for preparing the anti-ultraviolet spectacle lens are:

[0036] Polymethacrylate 99.1%;

[0037] Light shielding agent: magnesium oxide 0.11%, neodymium oxide 0.11%;

[0038] UV absorber: nickelocene 0.28%;

[0039] Free radical scavenger: Tetramethylpyridine 0.16%;

[0040] Compatibilizer: Oxazoline 0.24%.

Embodiment 3

[0042] An anti-ultraviolet spectacle lens, the raw materials and weight percentages thereof for preparing the anti-ultraviolet spectacle lens are:

[0043] Poly-p-chlorostyrene 99.2%;

[0044] Light shielding agent: samarium oxide 0.10%, silicon dioxide 0.10%;

[0045] UV absorber: oxazoline ring 0.29%;

[0046] Free radical scavenger: Tetramethylpyridine 0.17%;

[0047] Compatibilizer: Oxazoline 0.14%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com