Bismuth vanadate photo-anode as well as preparation method and application thereof

A technology of bismuth vanadate and photoanode, which is applied in the fields of clean energy and photoelectrochemistry, can solve the problems of slow photoanode water oxidation reaction kinetics, and achieve the effects of fast water oxidation kinetics, high photocurrent density, and easy-to-obtain reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

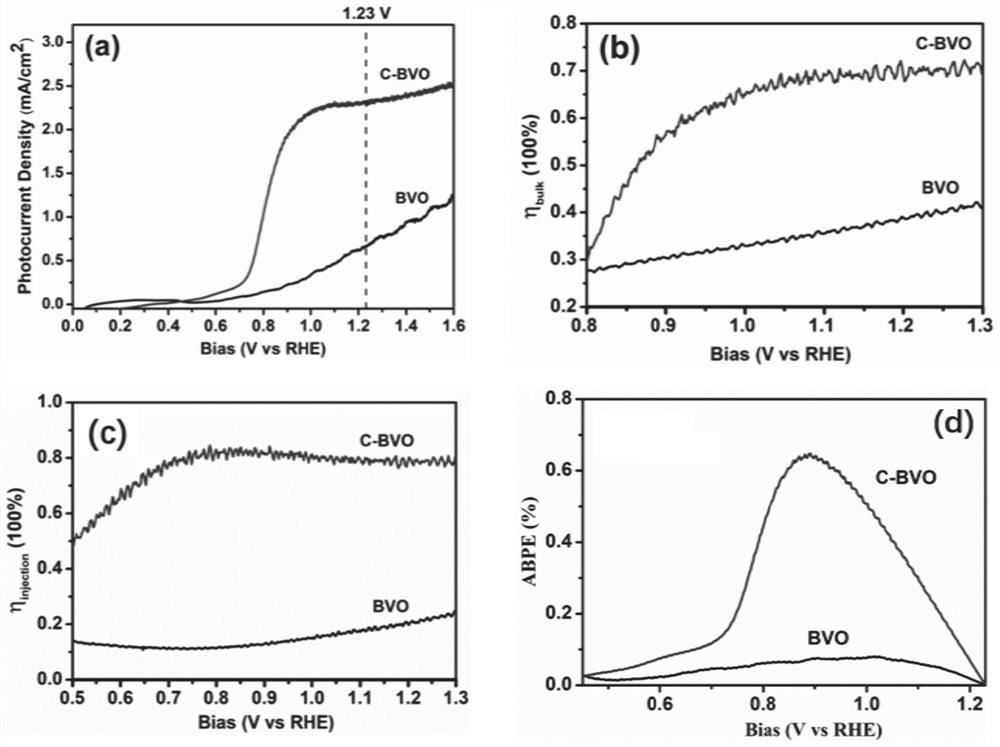

[0049] The third embodiment of the present invention provides an application of the above-mentioned bismuth vanadate photoanode in photoelectrocatalytic decomposition of water to produce hydrogen and oxygen.

[0050] The fourth embodiment of the present invention provides a photoelectrochemical electrolysis cell, including a photoanode and a photocathode, and the photoanode is the above-mentioned bismuth vanadate photoanode.

[0051] In order to enable those skilled in the art to understand the technical solution of the present invention more clearly, the technical solution of the present invention will be described in detail below in conjunction with specific examples and comparative examples.

[0052] The test materials used in the following examples are all conventional test materials in the art, and can be purchased through commercial channels.

Embodiment 1

[0054] A BVO photoanode with a fast water oxidation rate and a preparation method thereof, comprising the steps of:

[0055] (1) Ultrasonic cleaning of FTO conductive glass:

[0056] First cut with a glass cutter to obtain FTO conductive glass with a size of 3cm×4cm, then ultrasonically clean with acetone, ethanol and isopropanol for 30 minutes, and finally store in isopropanol solvent.

[0057] (2) Synthesis of carbon spheres by hydrothermal method:

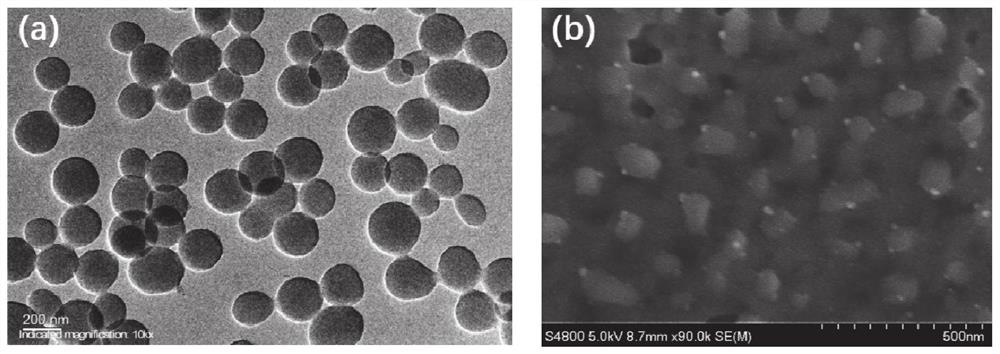

[0058] Dissolve 4 g of glucose in 50 mL of deionized water and stir for 15 min to obtain a clear solution. Then the solution was transferred to a reaction kettle with a 100 ml polytetrafluoroethylene liner, and subjected to hydrothermal reaction at 180° C. for 3.5 hours to obtain a brown solution. Then the brown solution was centrifuged three times with pure water and ethanol at 12000rpm / 3 minutes to obtain carbon spheres with a relatively uniform size, which were dispersed in the ethanol solution for later use.

[0059] (3) ...

Embodiment 2

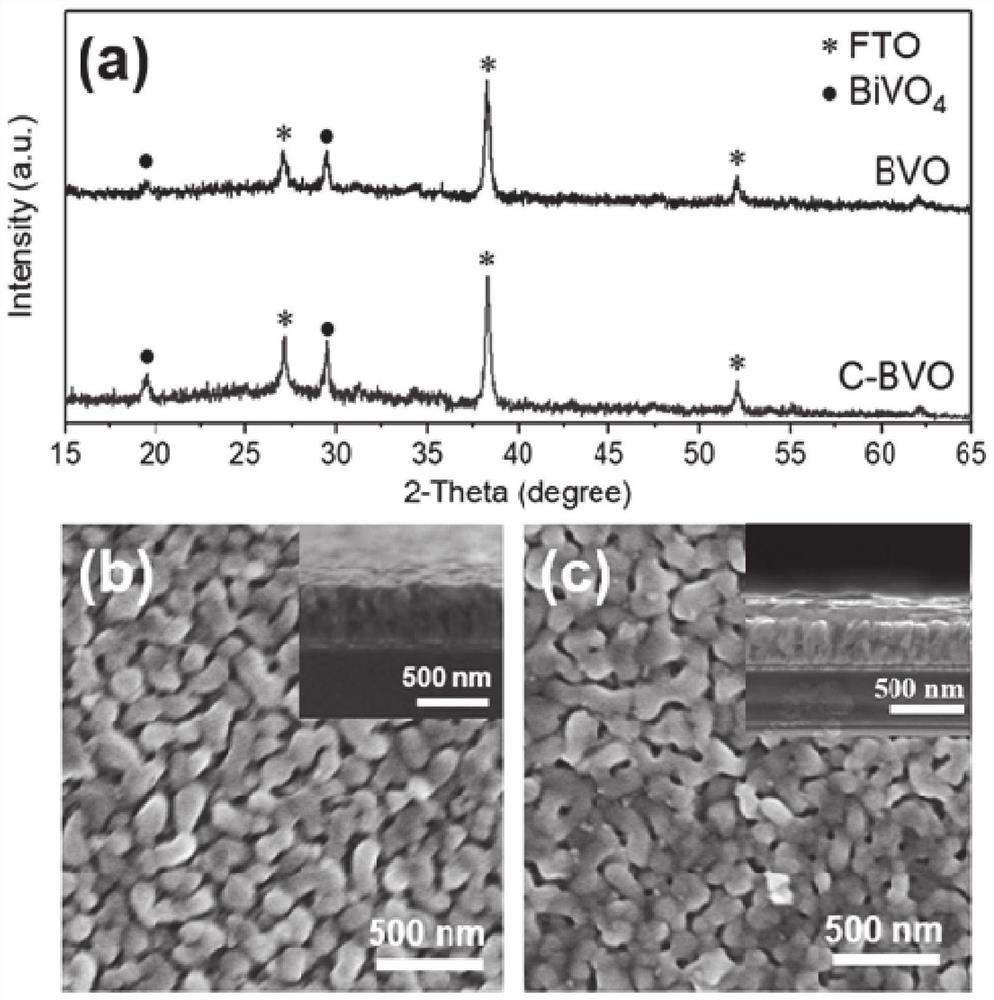

[0068] This example prepares composite BVO photoanodes with different contents of carbon spheres, the preparation method is the same as in Example 1, the difference is that the concentrations of the carbon spheres used in the spin coating in step (5) are respectively: 0.25C, 0.5C, 1C, 2C, The prepared photoanodes are marked as 0.25C-BVO, 0.5C-BVO, C-BVO, 2C-BVO, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Photocurrent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com