A kind of preparation method of reactive asphalt modifier, modified asphalt and asphalt mixture

A technology of asphalt modifier and modified asphalt, which is used in building thermal insulation materials, climate change adaptation, building components, etc. It can solve the problems of separation of asphalt and modifier, affecting the performance of modified asphalt, energy consumption and time consumption. , to achieve the effect of reducing pavement maintenance, improving impact resistance and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

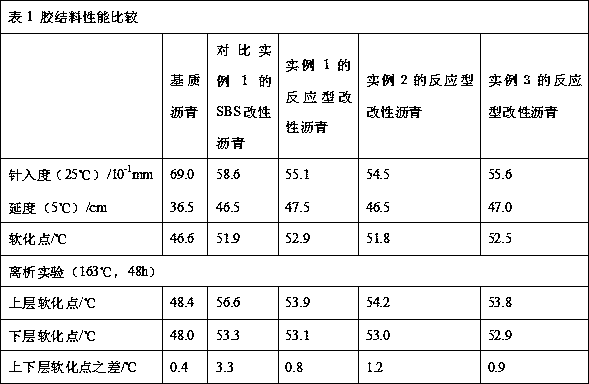

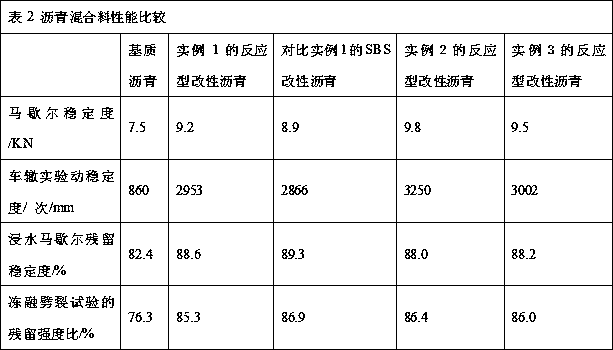

[0026] The invention provides a preparation method of reactive modified asphalt, comprising the steps of:

[0027] (1) Precisely measure coumarone resin, rosin resin and flexible unsaturated polyester into the reactor, heat to 140-150°C, stir for 15 minutes, then add low-temperature modifier, continue stirring for 15 minutes, cool down to 50°C, and Component A is obtained by granulation;

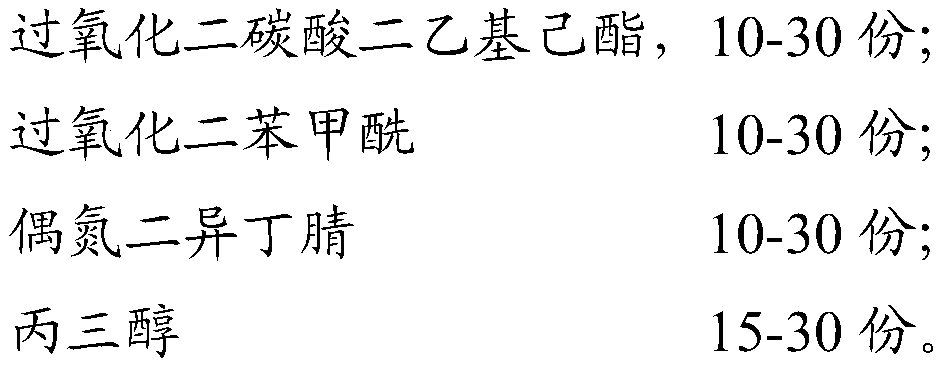

[0028] (2) Put glycerol into the reaction kettle and turn on the stirring device, and add diethylhexyl peroxydicarbonate, dibenzoyl peroxide, and azobisisobutyronitrile respectively, stir for 15 minutes, and control the temperature at 20- 40°C, to obtain component B;

[0029] (3) Mix component A of the reactive asphalt modifier obtained in step (1) with base asphalt at 130-140°C and stir for 15-20 minutes, then add the reactive asphalt obtained in step (2) Component B of the modifier is uniformly stirred at 130-140°C for 10-20 minutes to obtain reactive modified asphalt.

[0030] Componen...

Embodiment 1

[0038] Preparation of reactive modified asphalt (take the preparation of 100kg of reactive modified asphalt component A, 100kg of reactive modified asphalt component B, and one ton of reactive modified asphalt as a standard example):

[0039] (1) Heat 40kg of coumarone resin, 20kg of rosin resin, and 35kg of linseed oil-type unsaturated polyester to 140°C respectively, put them into the reaction kettle according to accurate measurement, and keep stirring for 15 minutes. Add 5kg of low molecular weight polyethylene and keep stirring for 15 minutes. Cool down to below 50°C, granulate for later use; wherein, the above-mentioned maintenance stirring speed is: rotation 75±5 revolutions / minute, revolution 45±5 revolutions / minute; stirring temperature: when the material is stirred, the temperature is maintained at 140-150°C.

[0040] (2) Put 30kg of glycerol into the reaction kettle, put in 20kg of diethylhexyl peroxydicarbonate, 20kg of dibenzoyl peroxide, and 30kg of azobisisobutyr...

Embodiment 2

[0047] Preparation of reactive modified asphalt (take the preparation of 100kg of reactive modified asphalt component A, 100kg of reactive modified asphalt component B, and one ton of reactive modified asphalt as a standard example):

[0048] (1) Heat 20kg of coumarone resin, 40kg of rosin resin, and 39kg of dicyclopentadiene-modified unsaturated polyester to 140°C respectively, put them into the reaction kettle according to precise measurement, and keep stirring for 15 minutes. 1 kg of aliphatic hydrocarbon resin was added and stirring was maintained for 15 minutes. Cool down to below 50°C, granulate for later use; wherein, the above-mentioned maintenance stirring speed is: rotation 75±5 revolutions / minute, revolution 45±5 revolutions / minute; stirring temperature: when the material is stirred, the temperature is maintained at 140-150°C.

[0049] (2) Put 15kg of glycerol into the reaction kettle, put in 30kg of diethylhexyl peroxydicarbonate, 30kg of dibenzoyl peroxide, and 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com