Method for preparing coalbed methane hydrate

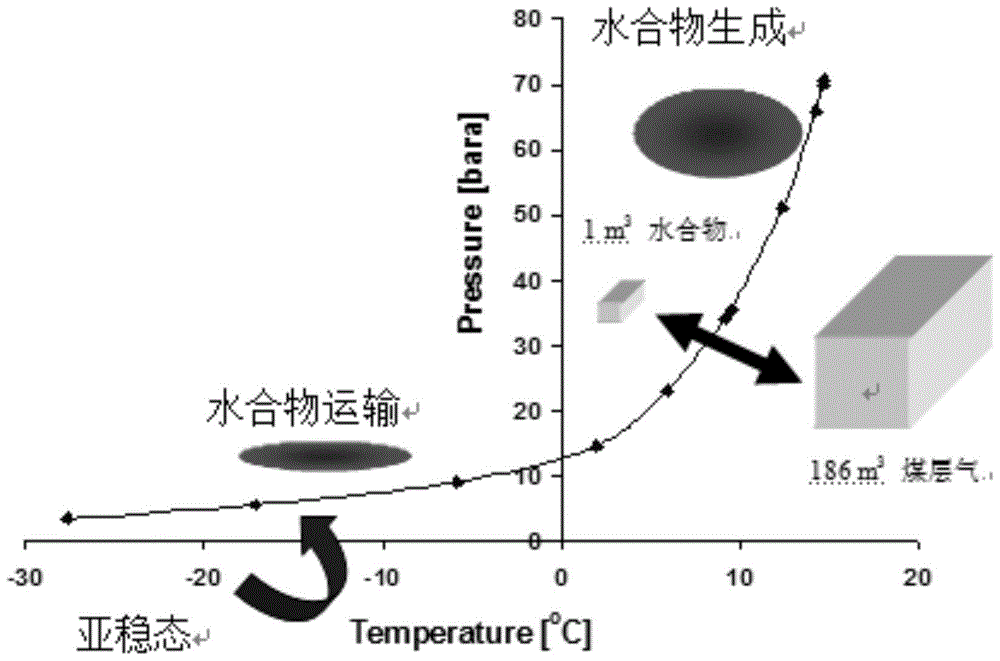

A technology of coalbed methane and hydrate, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of violent fluctuations in the production process, difficulty in control, and different pipeline pressures, so as to improve separation efficiency and production efficiency, promote rapid production, The effect of increasing the gas content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

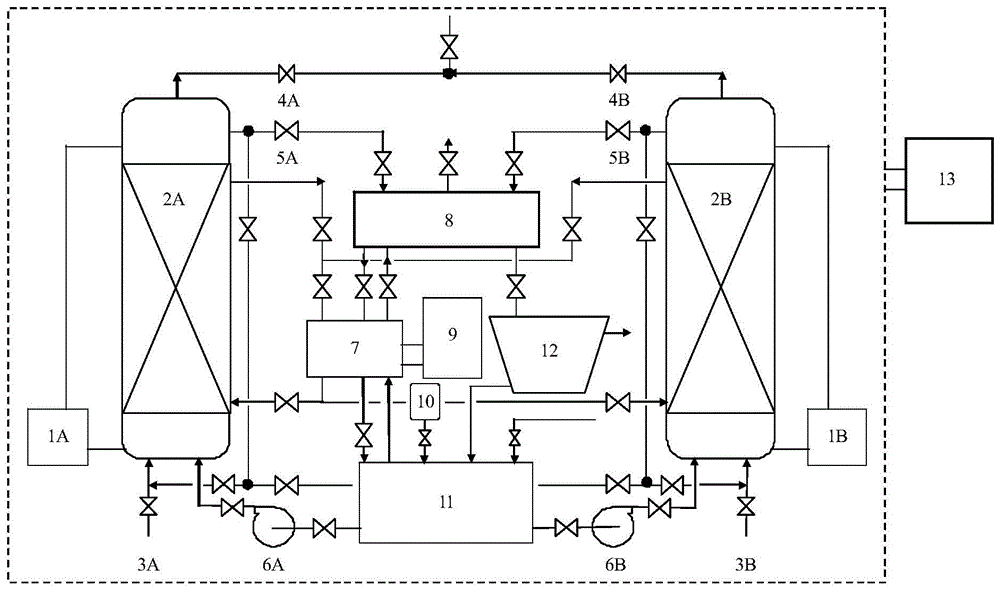

[0085] Start the cold storage unit 9 and the refrigeration unit 7, supply chilled water to the heat exchange mechanism set in the water tank 11 and the intermediate storage tank 8, and control the temperature in the entire internal circulation flow reactor 2 at 4 ° C; start the water pump 6 and The central control system 13 pumps water equipped with additives into the reaction unit of the reactor. When the water level at the top of the reactor exceeds the top of the internal circulator and reaches the designated liquid level, open the discharge valve 5 at the outlet of the bypass pipe, adjust the opening degree of the valve and the displacement of the transfer pump 6, so that the water passes through the discharge valve 5 and the intermediate storage tank 8. The separator 12 and the water tank 11 form a stable water cycle; after that, 98% of the coal bed gas enters the tube side 24 of the internal circulation flow reactor 2 through the flow regulating valve and the gas nozzle, ...

Embodiment 2

[0088] Adopt the technological process of embodiment 1, but the pressure in the reaction tower is 7.3MPa, and the temperature in the tower is 6.5 ℃. The reaction produces a viscous colloidal hydrate slurry, and the gas content of methane in the hydrate reaches 174V / V.

Embodiment 3

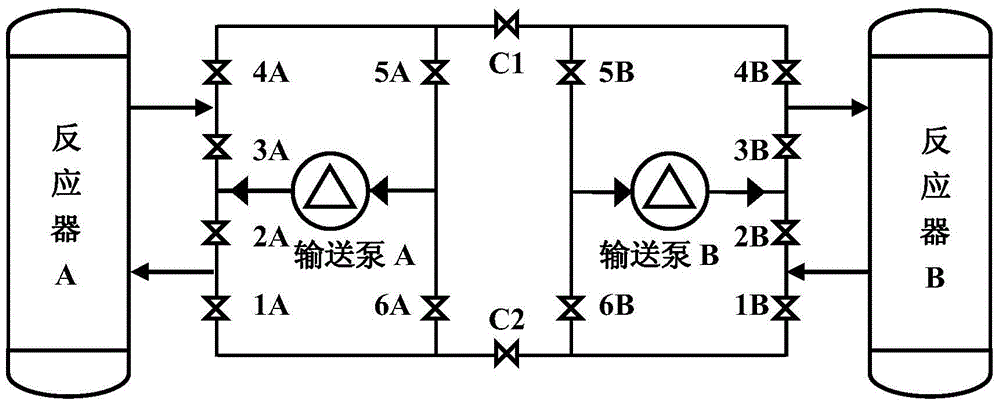

[0090] Adopt the technological process of embodiment 1, but the pressure in the reaction tower is 7.3MPa, and the temperature in the tower is 6 ℃. The raw material concentration of coalbed methane is about 50%, according to the process conversion unit figure 2 The control logic controls the process to form a multi-stage countercurrent hydration reaction process, and the reaction produces a viscous colloidal hydrate slurry, and the methane gas content in the hydrate reaches about 160V / V. This method has remarkable economy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com