Method for producing chitinase through fermentation of thermobifida fusca

A chitinase and thermal cracking technology, applied in the field of bioengineering, can solve the problem of not many high-yield and high-temperature resistant chitinase, and achieve the effects of wide tolerance range, easy cultivation and short fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Preliminary experiment of brown thermobifidafusca (Thermobifidafusca) producing chitinase

[0033]The production of chitinase by Thermobista spp. was confirmed by the plate transparent circle method. The selection medium for producing the transparent circle is 5g of casein, 2g of water-soluble chitin, 7ml of 5% dipotassium hydrogen phosphate, 5ml of magnesium sulfate 1 / 10,000, 20g of agar and 1000ml of distilled water. Spot the test strains on a plate (diameter 9cm), spot 6 strains per plate, and observe whether a transparent circle is formed after culturing at 30°C for 5-7 days. Serratia marcescens known to produce chitinase was used as Control strain. The bacterial strains that produced transparent circles on the chitin plate were collected on the same plate and spot-connected, and the colonies and transparent circles were observed after 7 days. The results are shown in figure 1 .

Embodiment 2

[0034] Embodiment 2: the method for producing chitinase by fermentation of brown thermobifidafusca (Thermobifidafusca)

[0035] Put Thermophilia brown into a 50mL Erlenmeyer flask containing 10mL of enriched medium, cultivate it at 55°C and 220r / min for 24h, and transfer the first-grade seed liquid into the flask with 3% inoculum In a 250mL Erlenmeyer flask with 100mL of enriched medium, culture at 55°C and 220r / min for about 24h to prepare the secondary seed solution. The secondary seed solution was introduced into the fermentation medium with an inoculation amount of 2.5%, and cultured at 55° C. and 220 r / min for 52 hours to obtain a chitinase product.

[0036] Enriched medium components are in mass percent, including NaCl1.20%, (NH 4 ) 2 SO 4 2.49%, KH 2 PO 4 0.72%, Na 2 HPO 4 7.30%, EDTA0.02%, MgSO 4 ·7H 2 O0.08%, FeSO 4 ·7H 2 O0.008%, MnSO 4 .7H 2 O0.006%, CaCl 2 .2H 2 O0.005%, biotin 0.00008%, ammonium sulfate 0.00008%, yeast powder 0.016%, and adjust the ...

Embodiment 3

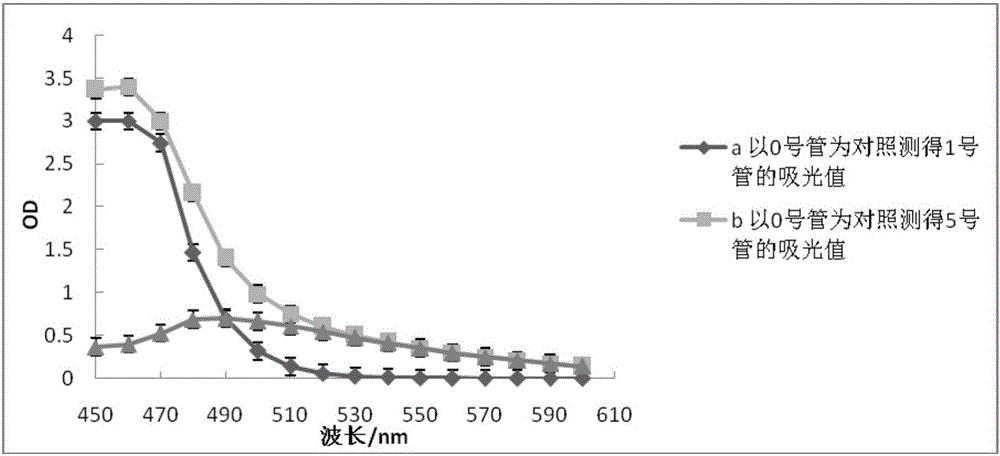

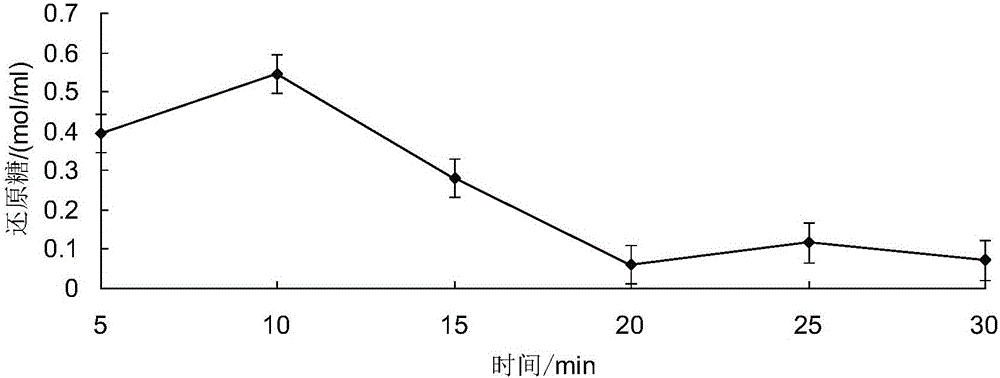

[0038] Embodiment 3: wavelength selection and standard curve drawing

[0039] Accurately weigh 0.258 g of glucosamine hydrochloride dried at 100°C to constant weight, add distilled water to dissolve and make the volume to 100 ml, and prepare a standard solution with a concentration of 12 μmol / mL. According to Table 1, add the solution to each 25ml graduated tube, develop the color in a boiling water bath for 5min, add distilled water to make the volume to 25ml after cooling. Firstly, with No. 0 tube (distilled water) as a reference, scan the absorbance wavelength curves of No. 0 tube and any other tube (No. 5 tube is selected in this experiment), and determine the measured absorption wavelength according to the maximum difference or maximum peak value of the absorption value. .

[0040] For the drawing of the standard curve, select tube No. 1 as a reference, scan the absorption wavelengths of tubes 2 to 7, and obtain the standard curve and linear correlation coefficient at di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com