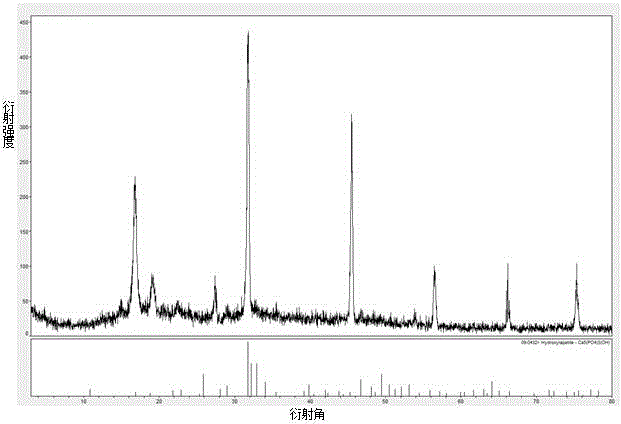

Polylactic acid-hydroxyapatite whisker compound porous scaffold for bone tissue engineering and preparation method thereof

A technology of hydroxyapatite and bone tissue engineering, applied in the field of biomedical materials, can solve problems such as lower requirements, and achieve the effects of improving mechanical strength, excellent biocompatibility, and good osteoconductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

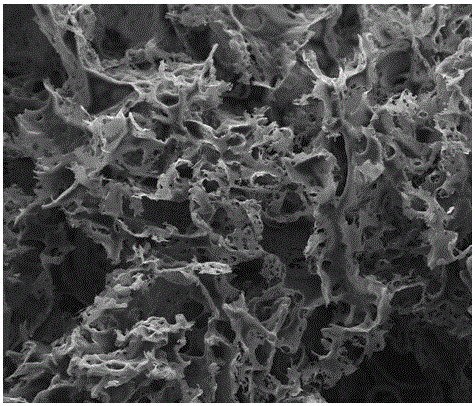

[0029] The polylactic acid / hydroxyapatite whisker composite porous scaffold for bone tissue engineering described in this example, the hydroxyapatite whisker accounts for 0.5wt% of the total amount of polylactic acid and hydroxyapatite whisker, the pores of the composite porous scaffold The ratio is 91.1%, and the diameter of the irregular through-holes is 100-500 μm.

[0030] The preparation method of the polylactic acid / hydroxyapatite whisker composite porous scaffold for bone tissue engineering in this example, the specific steps are as follows:

[0031] (1) According to the ratio of pore-forming agents sodium chloride and potassium chloride to 92% of the total volume of sodium chloride, potassium chloride and polylactic acid, add the mixture of pore-forming agents sodium chloride and potassium chloride to polylactic acid In the organic solvent of chloroform, fully stir to make it uniformly dispersed, wherein the particle size of sodium chloride and potassium chloride is 10...

Embodiment 2

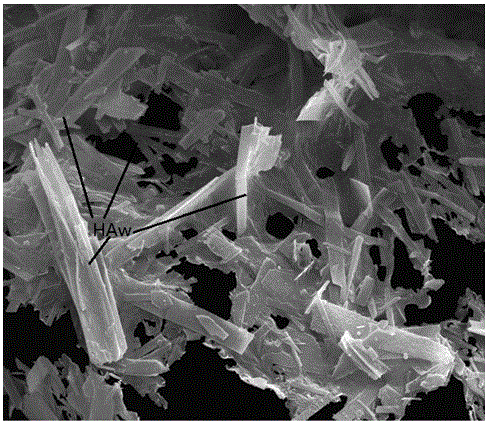

[0043] The polylactic acid / hydroxyapatite whisker composite porous scaffold for bone tissue engineering described in this embodiment, the hydroxyapatite whisker accounts for 10wt% of the total amount of polylactic acid and hydroxyapatite whisker, the porosity of the composite porous scaffold It is 80.0%, and the diameter of the irregular through hole is 50-400μm.

[0044] The preparation method of the polylactic acid / hydroxyapatite whisker composite porous scaffold for bone tissue engineering in this example, the specific steps are as follows:

[0045] (1) According to the ratio of the pore-forming agent potassium chloride to 80.5% of the total volume of potassium chloride and polylactic acid, the pore-forming agent potassium chloride is added to the mixed solvent of dichloromethane and chloroform of polylactic acid, fully Stir to disperse evenly, wherein the particle size of potassium chloride is 50-400 μm;

[0046] (2) Add hydroxyapatite whiskers to the mixture prepared in ...

Embodiment 3

[0052] The polylactic acid / hydroxyapatite whisker composite porous scaffold for bone tissue engineering described in this embodiment, the hydroxyapatite whisker accounts for 50wt% of the total amount of polylactic acid and hydroxyapatite whisker, the porosity of the composite porous scaffold It is 45.8%, and the diameter of the irregular through hole is 100-600μm.

[0053] The preparation method of the polylactic acid / hydroxyapatite whisker composite porous scaffold for bone tissue engineering in this embodiment, the specific steps include the following:

[0054] (1) According to the ratio of the pore-forming agent calcium sulfate to 50% of the total volume of calcium sulfate and polylactic acid, add the pore-forming agent to the carbon tetrachloride organic solvent of polylactic acid, stir well to disperse it evenly, and calcium sulfate The particle size is 100-600μm;

[0055] (2) Add hydroxyapatite whiskers to the mixture prepared in step (1) according to the proportion of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com