MoS2/TiO2 two-dimensional composite nanometer photocatalyst and preparation method and application thereof

A nano-photocatalyst and nano-sheet technology, applied in the field of photocatalysis, can solve the problem of low quantum separation efficiency, and achieve the effects of enhanced photocatalytic performance, high production efficiency, and easy control of the preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

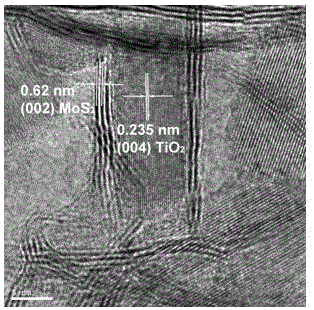

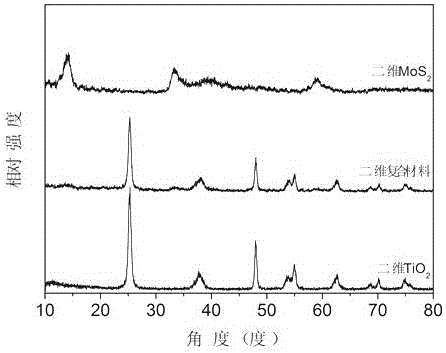

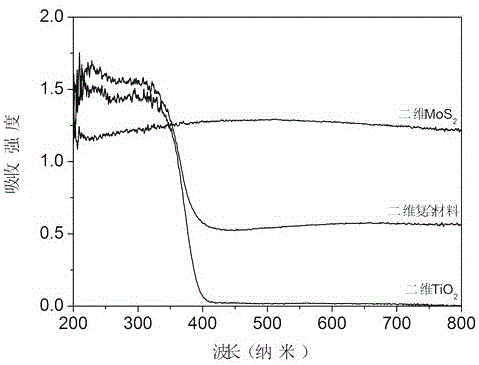

[0031] Mix tetrabutyl titanate and HF at a volume ratio of 10:1 to form a precursor solution, place the precursor solution in a hydrothermal reaction kettle for hydrothermal reaction, the temperature of the hydrothermal reaction is 160°C, and the constant temperature time is 15 hours; The solid-liquid mixture after the hydrothermal reaction is subjected to solid-liquid centrifugation, the liquid is discarded, the solid product is washed twice with deionized water, and then dried at 60°C for 6 hours; the dried product is ground into powder to obtain {001} facet exposed TiO 2 Nanoparticles; TiO with {001} faces exposed 2 Nanoparticles, sodium molybdate and thiourea were mixed into a precursor solution according to the mass ratio of 100:3:6, and placed in a hydrothermal reaction kettle for hydrothermal reaction. The temperature of the hydrothermal reaction was 150 ° C, and the constant temperature time was 15 hours; The solid-liquid mixture after the hydrothermal reaction is sub...

Embodiment 2

[0033]Tetrabutyl titanate and HF were mixed into a precursor solution at a volume ratio of 10:2, and the precursor solution was placed in a hydrothermal reaction kettle for hydrothermal reaction. The temperature of the hydrothermal reaction was 170°C, and the constant temperature time was 18 hours; The solid-liquid mixture after the hydrothermal reaction is subjected to solid-liquid centrifugation, the liquid is discarded, the solid product is washed 3 times with deionized water, and then dried at 70°C for 7 hours; the dried product is ground into powder to obtain {001} facet exposed TiO 2 Nanoparticles; TiO with {001} faces exposed 2 Nanoparticles, sodium molybdate and thiourea were mixed into a precursor liquid according to the mass ratio of 100:6:12, and placed in a hydrothermal reaction kettle for hydrothermal reaction. The hydrothermal reaction temperature was 160°C, and the constant temperature time was 20 hours; The solid-liquid mixture after the hydrothermal reaction ...

Embodiment 3

[0035] Tetrabutyl titanate and HF were mixed into a precursor solution at a volume ratio of 10:3, and the precursor solution was placed in a hydrothermal reaction kettle for hydrothermal reaction. The hydrothermal reaction temperature was 180°C, and the constant temperature time was 24 hours; The solid-liquid mixture after thermal reaction is subjected to solid-liquid centrifugal separation, the liquid is discarded, the solid product is washed 4 times with deionized water, and then dried at 80°C for 8 hours; the dried product is ground into powder to obtain { 001} facet exposed TiO 2 Nanoparticles; TiO with {001} faces exposed 2 Nanoparticles, sodium molybdate and thiourea were mixed into a precursor solution according to the mass ratio of 100:15:30, and placed in a hydrothermal reaction kettle for hydrothermal reaction. The hydrothermal reaction temperature was 170°C, and the constant temperature time was 25 hours; The solid-liquid mixture after the hydrothermal reaction is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com