Novel thermal-insulated pipeline material and preparation method thereof

A thermal insulation pipeline and a new type of technology, applied in the field of materials, can solve the problems of rising economic losses and rising costs in the power and heat production industry, and achieve the effects of high service temperature, good flame retardancy and low thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

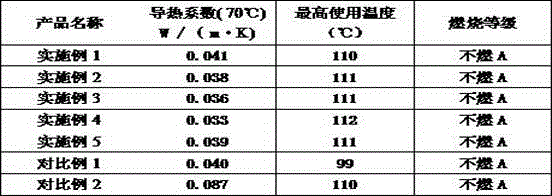

Examples

Embodiment 1

[0017] A new type of thermal insulation pipe material, prepared from the following ingredients in parts by weight: 30 parts of polybutene, 10 parts of bisphenol A epoxy resin, 10 parts of isopropanol, 0.1 part of magnolol, 1 part of polyethylene wax, 0.5 part of dibutyltin maleate, 0.2 part of dioctyltin oxide, 1 part of nano silicon dioxide, 1 part of sodium lauryl sulfate, 0.5 part of sodium dioctyl succinate sulfonate, 0.1 part of propylene glycol alginate, trihard 0.5 part of fatty acid glyceride, 0.1 part of kojic acid palmitate, 1 part of polypropylene fiber, 0.5 part of silane coupling agent KH-5600, and 1 part of phenyltriethoxysilane.

[0018] The preparation method of the above-mentioned new thermal insulation pipeline material is as follows: (1) Mix nano-silica, silane coupling agent KH-560, phenyltriethoxysilane, isopropanol and water, and use a magnetic stirrer at a speed of 80r / min Stir for 40 minutes and then ultrasonically disperse for 20 minutes; (2) Filter an...

Embodiment 2

[0020] A new type of thermal insulation pipe material, prepared from the following ingredients in parts by weight: 35 parts of polybutene, 15 parts of bisphenol A epoxy resin, 15 parts of isopropanol, 0.15 parts of magnolol, 1.5 parts of polyethylene wax, 0.75 parts of dibutyltin maleate, 0.35 parts of dioctyltin oxide, 1.5 parts of nano silicon dioxide, 1.5 parts of sodium lauryl sulfate, 0.75 parts of sodium dioctyl succinate sulfonate, 0.15 parts of propylene glycol alginate, trihard 0.75 parts of fatty acid glyceride, 0.15 parts of kojic acid palmitate, 1.5 parts of polypropylene fiber, 0.75 parts of silane coupling agent KH-5600, and 1.5 parts of phenyltriethoxysilane.

[0021] The preparation method of the above-mentioned new thermal insulation pipeline material is as follows: (1) Mix nano-silica, silane coupling agent KH-560, phenyltriethoxysilane, isopropanol and water, and use a magnetic stirrer at a speed of 90r / min Stir for 50 minutes and then ultrasonically dispers...

Embodiment 3

[0023] A new type of thermal insulation pipe material, prepared from the following ingredients in parts by weight: 40 parts of polybutene, 20 parts of bisphenol A epoxy resin, 20 parts of isopropanol, 0.2 parts of magnolol, 2 parts of polyethylene wax, 1 part of dibutyltin maleate, 0.5 part of dioctyltin oxide, 2 parts of nano silicon dioxide, 2 parts of sodium lauryl sulfate, 1 part of sodium dioctyl succinate sulfonate, 0.2 part of propylene glycol alginate, trihard 1 part of fatty acid glyceride, 0.2 part of kojic acid palmitate, 2 parts of polypropylene fiber, 1 part of silane coupling agent KH-5601, 2 parts of phenyltriethoxysilane.

[0024] The preparation method of the above-mentioned new thermal insulation pipeline material is as follows: (1) Mix nano-silica, silane coupling agent KH-560, phenyltriethoxysilane, isopropanol and water, and use a magnetic stirrer at a speed of 100r / min Stir for 60 minutes and ultrasonically disperse for 30 minutes; (2) Filter and put in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com