Anti-corrosion and anti-radiation coating and preparation method thereof

A technology of anti-radiation coatings and raw materials, applied in the field of coatings, can solve problems such as insufficient adhesion, difficult construction, and insufficient functions, and achieve the effects of simple operation, excellent anti-corrosion, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

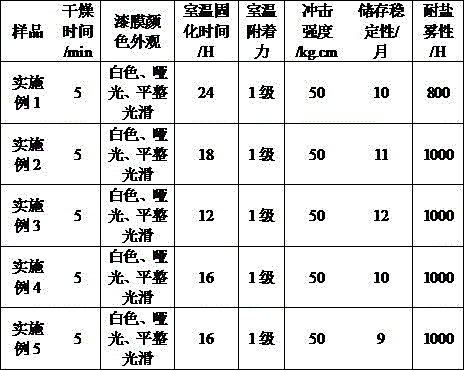

Examples

Embodiment 1

[0018] Embodiment 1 of the present invention provides an anti-corrosion and radiation-proof coating, which includes the following raw materials in parts by weight: 20 parts of novolak epoxy resin, 10 parts of expanded graphite, 5 parts of carbon nanotubes, 1 part of titanium dioxide, and hydroxypropyl methyl fiber 0.5 parts of plain powder, 8 parts of glass powder, 5 parts of talcum powder, 15 parts of mica powder, 10 parts of perlite, 1 part of dicyclopentenyloxyethyl acrylate and 10 parts of water, wherein each raw material in this embodiment is for industrial grade.

[0019] Preparation method: Under the condition of 40°C, uniformly mix novolac epoxy resin, expanded graphite and water to form the first mixed solution; add glass powder, talc powder, perlite and mica powder to the first mixed solution , and ultrasonically dispersed for 30 minutes to obtain a second mixed solution; adding carbon nanotubes, titanium dioxide, hydroxypropyl methylcellulose and dicyclopentenyloxye...

Embodiment 2

[0021] Embodiment 2 of the present invention provides an anti-corrosion and radiation-proof coating, which includes the following raw materials in parts by weight: 23 parts of novolak epoxy resin, 12 parts of expanded graphite, 7 parts of carbon nanotubes, 2 parts of titanium dioxide, hydroxypropyl methyl fiber 1 part of plain powder, 10 parts of glass powder, 7 parts of talcum powder, 17 parts of mica powder, 11 parts of perlite, 2 parts of dicyclopentenyloxyethyl acrylate and 13 parts of water, wherein each raw material in this embodiment is for industrial grade.

[0022] Preparation method: Under the condition of 50°C, uniformly mix novolac epoxy resin, expanded graphite and water to form the first mixed solution; add glass powder, talc powder, perlite and mica powder to the first mixed solution , and ultrasonically dispersed for 30 minutes to obtain a second mixed solution; adding carbon nanotubes, titanium dioxide, hydroxypropyl methylcellulose and dicyclopentenyloxyethyl...

Embodiment 3

[0024] Embodiment 3 of the present invention provides an anti-corrosion and radiation-proof coating, which includes the following raw materials in parts by weight: 25 parts of novolac epoxy resin, 13 parts of expanded graphite, 8 parts of carbon nanotubes, 3 parts of titanium dioxide, hydroxypropyl methyl fiber 1.5 parts of plain powder, 11 parts of glass powder, 8 parts of talcum powder, 18 parts of mica powder, 13 parts of perlite, 2 parts of dicyclopentenyloxyethyl acrylate and 15 parts of water, wherein each raw material in this embodiment is for industrial grade.

[0025] Preparation method: Under the condition of 60°C, uniformly mix novolac epoxy resin, expanded graphite and water to form the first mixed solution; add glass powder, mica powder, perlite and talc powder to the first mixed solution , and ultrasonically dispersed for 35 minutes to obtain a second mixed solution; carbon nanotubes, titanium dioxide, hydroxypropyl methylcellulose and dicyclopentenyloxyethyl acr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com