Preparation method of porous spherical biological carbon and application

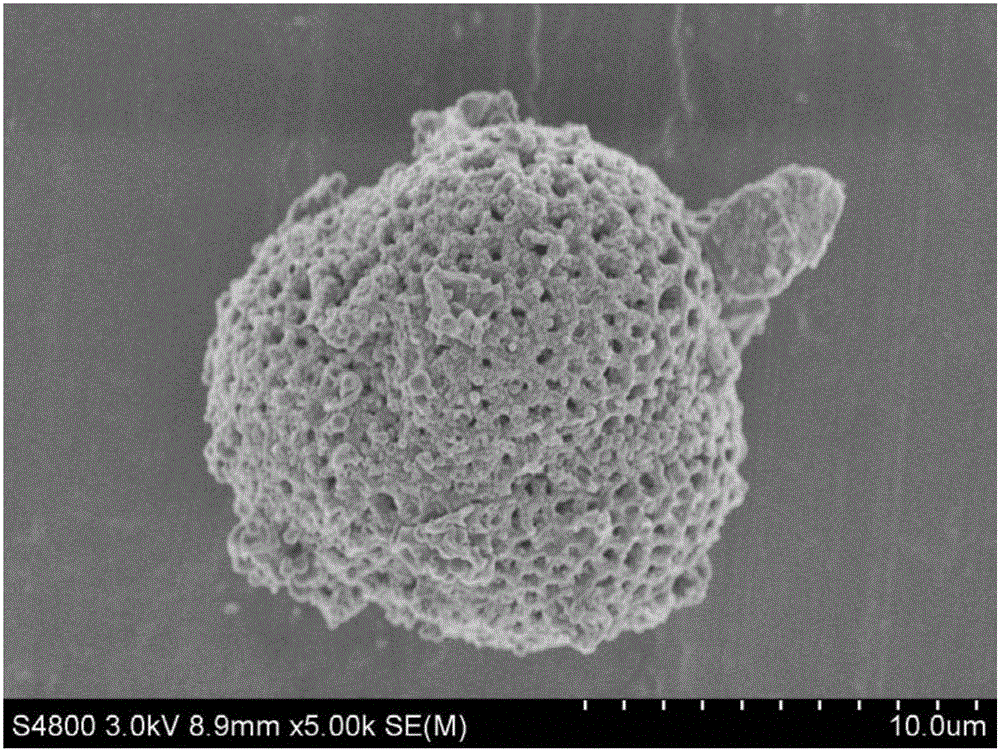

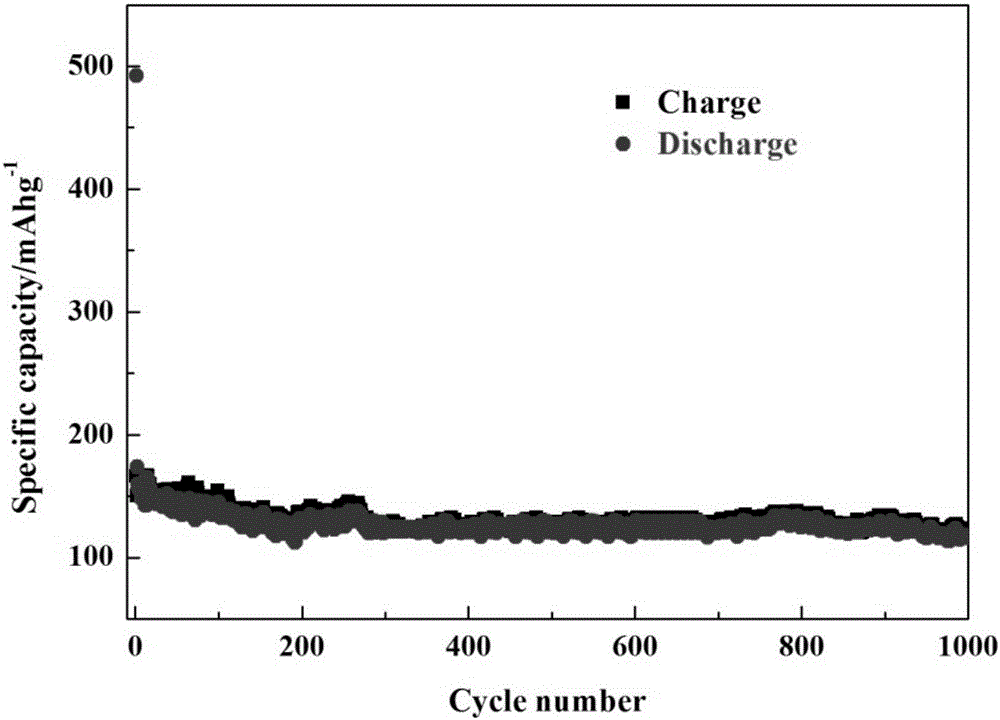

A bio-carbon and spherical technology, which is applied in the manufacture of hybrid/electric double-layer capacitors, electrical components, battery electrodes, etc., to achieve the effects of easy industrial production, excellent electrochemical performance, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A method for preparing porous spherical biochar, comprising the following steps:

[0024] Step 1: Weigh 0.5-2g of rapeseed pollen and place it in the lining of a hydrothermal kettle, add 30-50mL of deionized water and stir for 5-20min, then add 5-20mL of concentrated sulfuric acid and continue stirring for 30-60min until the pollen is completely dissolved. Described concentrated sulfuric acid, also can replace with concentrated nitric acid, concentrated hydrochloric acid, phosphoric acid etc.

[0025] Step 2: Install the inner lining of the hydrothermal kettle with prepared rapeseed pollen solution in the outer lining, fix it and place it in a homogeneous reactor, and heat up from room temperature at a rate of 5-10°C / min. Raise the temperature to 120-200° C., adjust the filling ratio of the hydrothermal reaction to 30%-80%, and react for 12-36 hours.

[0026] Step 3: Suction filter the solution after the hydrothermal reaction, wash with deionized water for 2 to 5 times...

Embodiment 1

[0033] Step 1: Weigh 0.5g of rapeseed pollen and place it in the lining of a hydrothermal kettle, add 30mL of deionized water and stir for 5min, then add 5mL of concentrated sulfuric acid and continue stirring for 30min until the pollen is completely dissolved.

[0034] Step 2: Install the inner lining of the hydrothermal kettle equipped with the prepared rape pollen solution in the outer lining, fix it and place it in a homogeneous reactor, and raise the temperature from room temperature to 120°C, adjust the filling ratio of the hydrothermal reaction to 80%, and react for 12 hours.

[0035] Step 3: Suction filter the solution after the hydrothermal reaction, first wash twice with deionized water, and then wash twice with absolute ethanol to remove impurities generated during the reaction. Then, the rapeseed pollen washed and suction-filtered was dried at a temperature of 60° C. for 12 hours.

[0036] Step 4: Put the dried rapeseed pollen in the quartz tube of the tube atmosp...

Embodiment 2

[0039] Step 1: Weigh 1g of rapeseed pollen and place it in the lining of a hydrothermal kettle, add 50mL of deionized water and stir for 10min, then add 10mL of concentrated sulfuric acid and continue stirring for 40min until the pollen is completely dissolved.

[0040] Step 2: Install the inner lining of the hydrothermal kettle equipped with the prepared rape pollen solution in the outer lining, fix it and place it in a homogeneous reactor, and raise the temperature from room temperature to 180°C, adjust the filling ratio of the hydrothermal reaction to 50%, and react for 24 hours.

[0041] Step 3: Suction filter the solution after the hydrothermal reaction, wash with deionized water for 3 times, and then wash with absolute ethanol for 3 times, so as to remove impurities generated during the reaction. Then, the washed and suction-filtered rapeseed pollen was dried at a temperature of 80° C. for 24 hours.

[0042] Step 4: Put the dried rapeseed pollen in the quartz tube of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com